- Wireless door lock control system (for HV model, with smart key system)

- Smart key system (for Entry function, HV model)

- Smart key system (for start function, HV model)

- Hybrid control system cannot be started

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001EFC2 |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - 02/2019] |

| Title: POWER DISTRIBUTION: MAIN BODY ECU: REMOVAL; 2019 MY RAV4 RAV4 HV [11/2018 - 02/2019] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the main body ECU (multiplex network body ECU) removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced (for HV Model)

|

Replaced Part or Performed Procedure |

Necessary procedures |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Disconnect cable from negative (-) auxiliary battery terminal |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Pre-collision system |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system (for HV model) |

|||

|

Reset back door close position |

Power back door system (for HV model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

Replacement of main body ECU (multiplex network body ECU) |

Code registration |

|

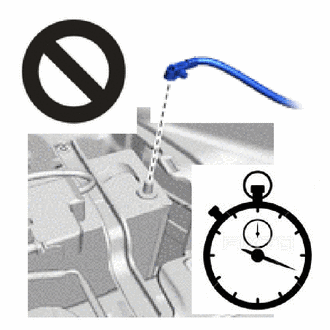

NOTICE:

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) auxiliary battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Auxiliary Battery Terminal

|

System Name |

See Procedure |

|---|---|

|

Vehicle enrolled in Toyota Entune system or safety connect system |

6 minutes |

|

Vehicle not enrolled in Toyota Entune system and safety connect system |

1 minute |

Necessary Procedure After Parts Removed/Installed/Replaced (for Gasoline Model)

|

Replaced Part or Performed Procedure |

Necessary procedures |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Disconnect cable from negative (-) auxiliary battery terminal |

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes) |

Stop and start system |

|

|

Perform steering sensor zero point calibration |

Lane control System |

||

|

Parking support brake system (for Gasoline model)* |

|||

|

Pre-collision System |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system (for Gasoline model) |

|||

|

Reset back door close position |

Power back door system (for Gasoline model) |

||

|

Back door lock initialization |

Power door lock control system |

||

w/ Smart Key System:

|

Code registration |

|

|

NOTICE:

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) auxiliary battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Auxiliary Battery Terminal

|

System Name |

See Procedure |

|---|---|

|

Vehicle enrolled in Toyota Entune system or safety connect system |

6 minutes |

|

Vehicle not enrolled in Toyota Entune system and safety connect system |

1 minute |

PROCEDURE

1. PRECAUTION

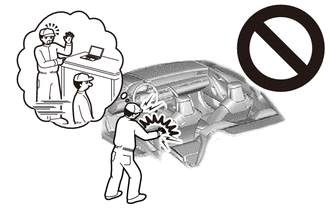

CAUTION:

Some of these service operations affect the SRS airbag system. Read the precautionary notices concerning the SRS airbag system before servicing.

NOTICE:

- After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

- Do not remove the main body ECU (multiplex network body ECU) except when replacing it.

- When removing the main body ECU (multiplex network body ECU), always replace it with a new one.

2. REMOVE DECK BOARD ASSEMBLY (for HV Model)

3. REMOVE REAR NO. 2 FLOOR BOARD (for HV Model)

4. REMOVE BATTERY HOLE COVER (for HV Model)

5. DISCONNECT CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL

- Wait at least 90 seconds after disconnecting the cable from the negative (-) auxiliary battery terminal to disable the SRS system.

- If the airbag deploys for any reason, it may cause a serious accident.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

6. REMOVE LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

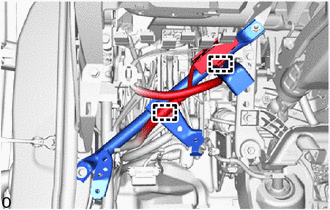

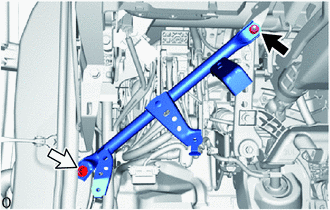

7. REMOVE NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY (for TMC Made)

|

(a) Detach the 2 wire harness clamps. |

|

(b) Remove the nut, bolt and No. 3 instrument panel to cowl brace sub-assembly.

|

Nut |

|

Bolt |

8. REMOVE CENTER INSTRUMENT PANEL BRACKET SUB-ASSEMBLY (for TMMC Made)

HINT:

Use the same procedure described as for the No. 3 instrument panel to cowl brace sub-assembly (for TMC Made).

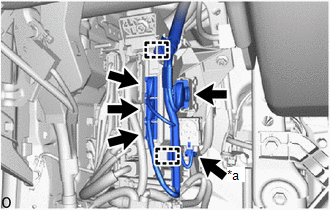

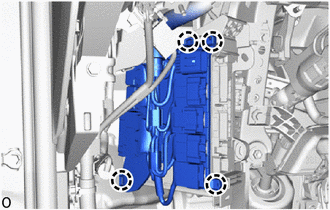

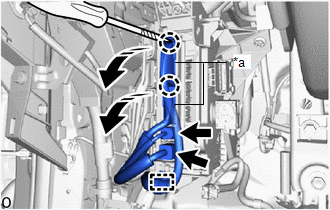

9. REMOVE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

|

(a) Detach the 2 wire harness clamps. |

|

(b) w/ Clearance Warning System:

(1) Disconnect the 5 connectors.

(c) w/o Clearance Warning System:

(1) Disconnect the 4 connectors.

(d) Using a thin-bladed screwdriver with its tip wrapped with protective tape, detach the claw and disconnect the 2 lever connectors.

|

*a |

Lever Connector |

|

Rotate in this Direction |

|

Protective Tape |

(e) Detach the wire harness clamp.

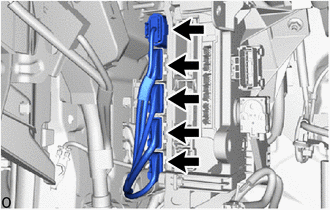

(f) Disconnect the 2 connectors.

|

(g) Disconnect the 5 connectors. |

|

|

(h) Remove the 2 nuts. |

|

(i) Detach the claw and disconnect the instrument panel junction block assembly with main body ECU.

|

(j) Detach the claw and remove the instrument panel junction block assembly with main body ECU from the connector holder. |

|

(k) Using a thin-bladed screwdriver with its tip wrapped with protective tape, detach the claw and disconnect the 2 lever connectors.

|

*a |

Lever Connector |

- |

- |

|

Rotate in this Direction |

|

Protective Tape |

(l) Detach the wire harness clamp and remove the instrument panel junction block assembly with main body ECU.

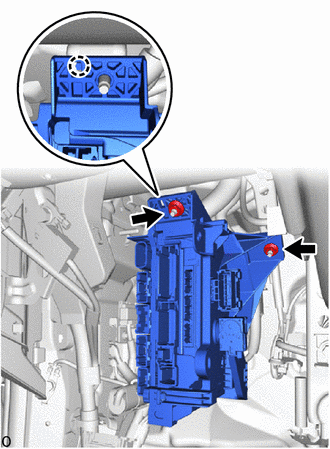

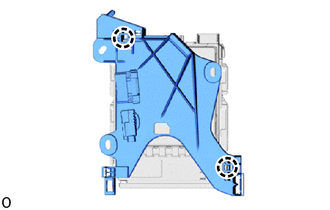

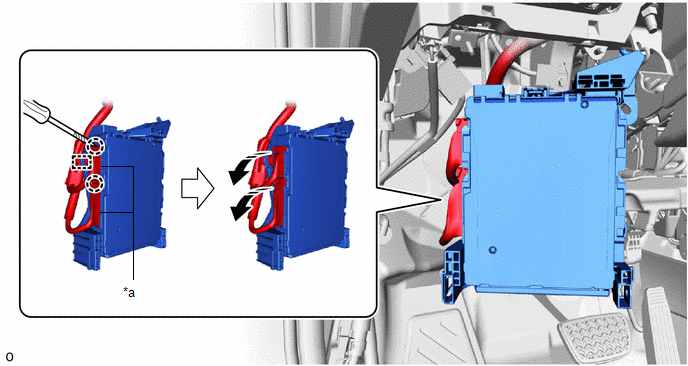

10. REMOVE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

|

(a) Detach the claw and remove the junction block bracket from the instrument panel junction block assembly with main body ECU. |

|

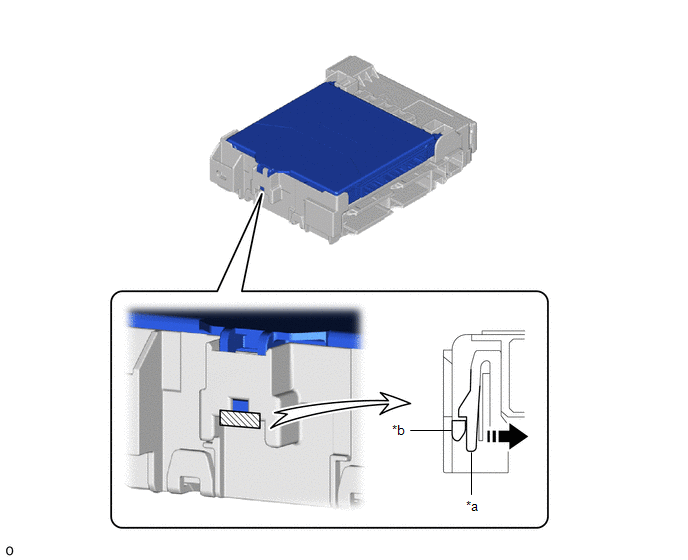

(b) Press the lock of the instrument panel junction block assembly and release the lock of the main body ECU (multiplex network body ECU) as shown in the illustration.

|

*a |

Instrument Panel Junction Block Assembly |

*b |

Main Body ECU (Multiplex Network Body ECU) |

|

Movement Direction |

|

Instrument Panel Junction Block Assembly Lock |

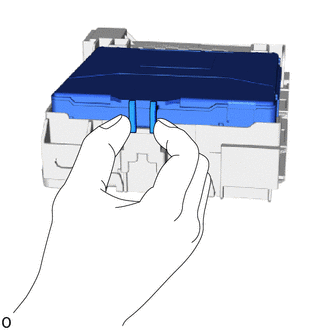

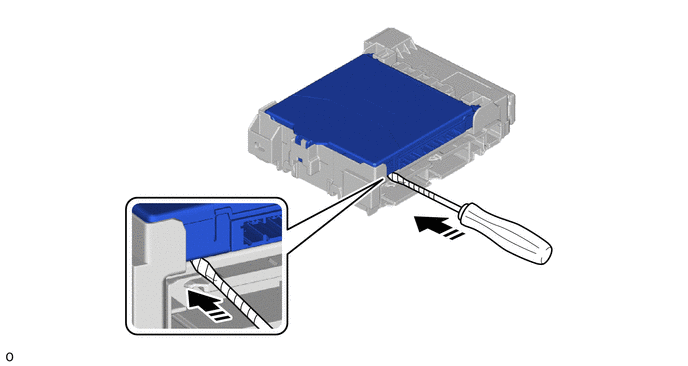

(c) While pressing the lock, horizontally insert a thin-bladed screwdriver with its tip wrapped with protective tape between the main body ECU (multiplex network body ECU) and instrument panel junction block assembly.

NOTICE:

Use a screwdriver with a diameter between 5.0 mm (0.197 in.) and 6.3 mm (0.248 in.) and a length of approximately 90 mm (3.54 in.).

|

Horizontally Insert a Thin-bladed Screwdriver |

|

Protective Tape |

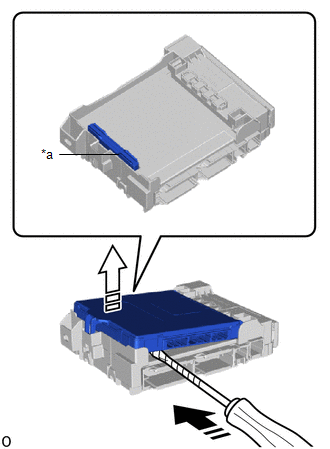

(d) When the thin-bladed screwdriver with its tip wrapped with protective tape is inserted, the internal connector lock is released.

|

*a |

Internal Connector |

|

Insert a Thin-bladed Screwdriver in this Direction |

|

Released in this Direction |

|

Protective Tape |

NOTICE:

- Do not twist the screwdriver to raise the main body ECU (multiplex network body ECU).

- Do not excessively insert the screwdriver. Otherwise, the internal connector terminals may become deformed or damaged.

- Replace the instrument panel junction block assembly when the connector terminal, the locking section, or the case is damaged or deformed.

|

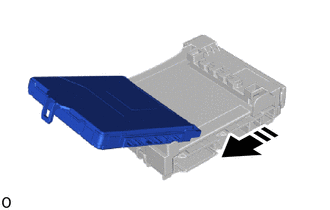

(e) Hold the rib of the main body ECU (multiplex network body ECU). |

|

(f) While rotating the main body ECU (multiplex network body ECU), completely release the lock.

|

Rotate in this Direction |

(g) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

|

Remove in this Direction |

|

|

|

![2019 - 2021 MY RAV4 RAV4 HV [11/2018 - 12/2021]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)