| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001EFC3 |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - 08/2020] |

| Title: POWER DISTRIBUTION: MAIN BODY ECU: INSTALLATION; 2019 - 2020 MY RAV4 RAV4 HV [11/2018 - 08/2020] | ||

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

When installing the main body ECU (multiplex network body ECU), always replace it with a new one.

PROCEDURE

1. INSTALL MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

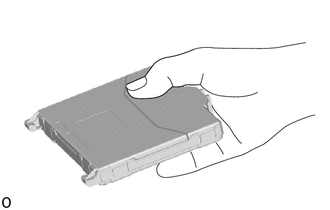

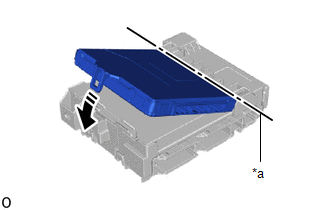

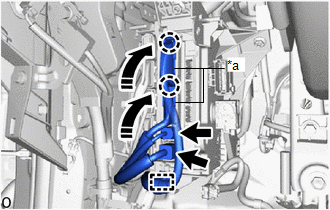

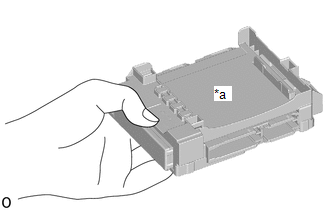

(a) Hold the main body ECU (multiplex network body ECU) with your dominant hand.

NOTICE:

- Do not touch the connector.

- Make sure foreign matter does not enter the terminals.

|

*a |

Connector |

|

(b) Hold the instrument panel junction block assembly with your other hand. NOTICE: Make sure there is no foreign matter in the fitting surface. |

|

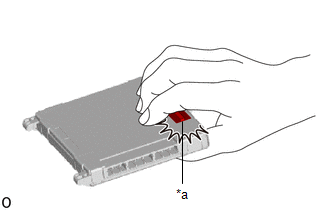

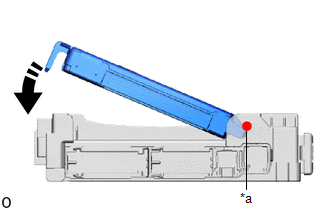

(c) Set the guide of the main body ECU (multiplex network body ECU) against the housing sidewall.

HINT:

Make sure the angle between the instrument panel junction block assembly and the main body ECU (multiplex network body ECU) is 20° or more.

|

*a |

20° or more |

|

Install in this Direction |

|

Housing Sidewall |

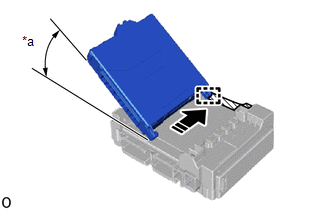

(d) Slide the guide of the main body ECU (multiplex network body ECU) along the housing sidewall in the direction indicated by the arrow.

|

Install in this Direction |

|

Housing Sidewall |

(e) Slide it until it contacts side A.

|

Install in this Direction |

|

Side A |

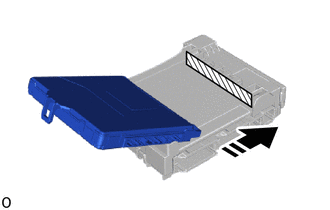

(f) Contact side A.

NOTICE:

Do not contact side A with the main body ECU (multiplex network body ECU) too hard.

|

Install in this Direction |

(g) While pressing the main body ECU (multiplex network body ECU) against side A (center of rotation) of the instrument panel junction block assembly, rotate it until it enters the lock of the instrument panel junction block assembly.

HINT:

The center of rotation is the one that contacts surface A.

|

*a |

Center of Rotation (Contacts Surface A) |

|

Rotate in this Direction |

|

*a |

Center of Rotation (Contacts Surface A) |

|

Rotate in this Direction |

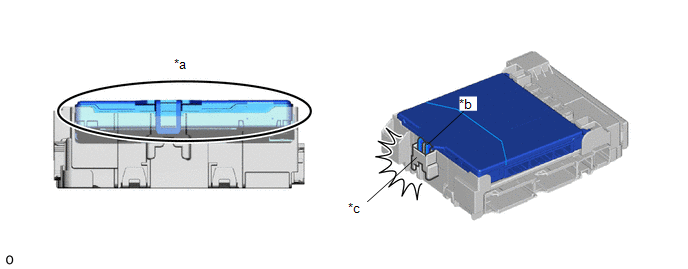

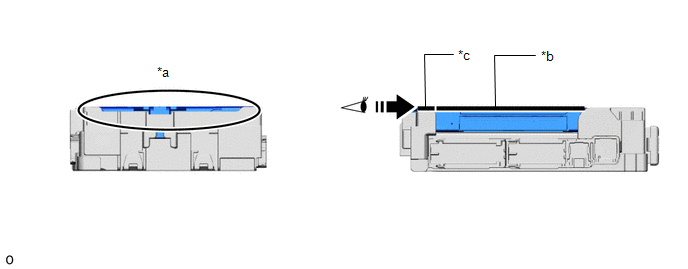

(h) Rotate it until it enters the lock of the instrument panel junction block assembly.

|

*a |

Before Locking |

*b |

Main Body ECU (Multiplex Network Body ECU) Lock |

|

*c |

Instrument Panel Junction Block Assembly Lock |

- |

- |

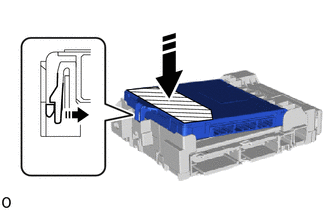

(i) Press the pressing area of the main body ECU (multiplex network body ECU).

|

Install in this Direction |

|

Pressing Area |

NOTICE:

-

Press it in one of the following ways.

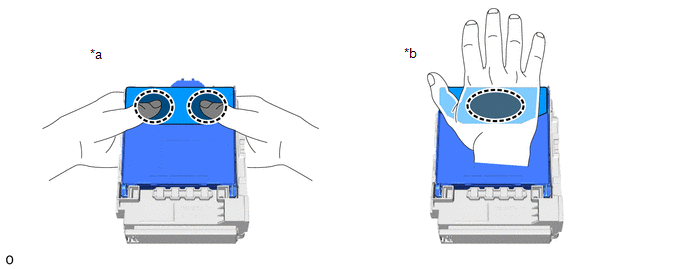

*a

Press the 2 sides of the main body ECU (multiplex network body ECU) with both hands.

*b

Press the center of the main body ECU (multiplex network body ECU) with one hand.

Place fingers or the palm of your hand here

-

-

- Do not hit on or put your weight on the main body ECU (multiplex network body ECU) when engaging the main body ECU (multiplex network body ECU).

- Check the engagement of the main body ECU (multiplex network body ECU) and the instrument panel junction block assembly by the locking sound.

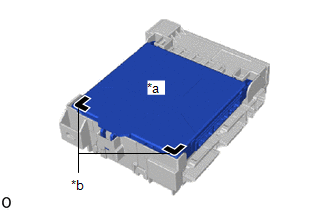

(j) Check that the back side of the main body ECU (multiplex network body ECU) and the rib surrounding the instrument panel junction block assembly are the same height.

|

*a |

Back Side of Main Body ECU (Multiplex Network Body ECU) |

|

*b |

Rib Surrounding Instrument Panel Junction Block Assembly |

|

*a |

After Locking (Height Matches) |

*b |

Back Side of Main Body ECU (Multiplex Network Body ECU) |

|

*c |

Rib Surrounding Instrument Panel Junction Block Assembly |

- |

- |

|

Confirm Visually |

- |

- |

|

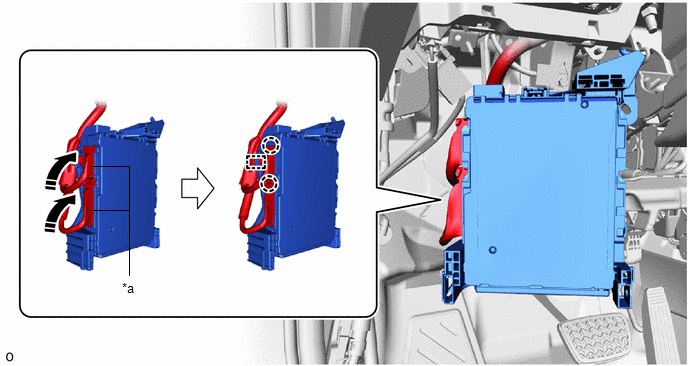

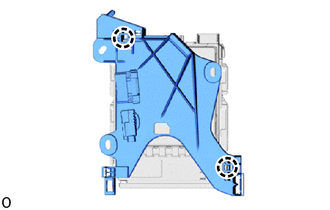

(k) Attach the claw to install the junction block bracket to the instrument panel junction block assembly. |

|

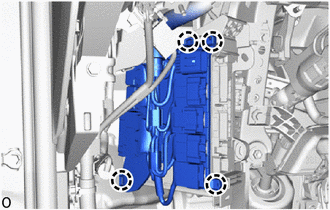

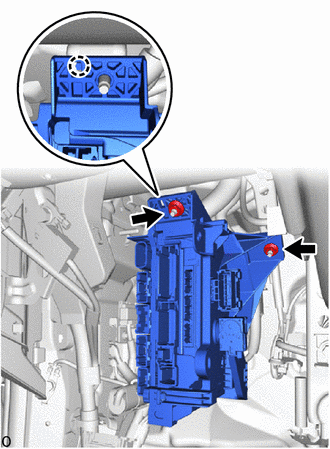

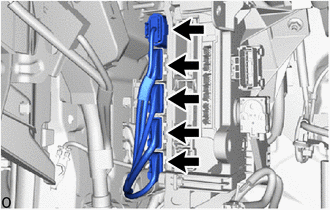

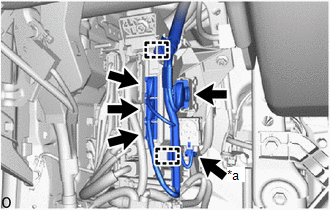

2. INSTALL INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

(a) Attach the wire harness clamp.

|

*a |

Lever Connector |

- |

- |

|

Rotate in this Direction |

- |

- |

(b) Attach the claw to connect the 2 lever connectors.

NOTICE:

Be sure to connect the connector securely.

|

(c) Attach the claw to install the instrument panel junction block assembly with main body ECU to the connector holder. |

|

|

(d) Attach the claw to install the instrument panel junction block assembly with main body ECU with the 2 nuts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

|

(e) Connect the 5 connectors. |

|

(f) Connect the 2 connectors.

|

*a |

Lever Connector |

|

Rotate in this Direction |

(g) Attach the wire harness clamp.

(h) Attach the claw to connect the 2 lever connectors.

NOTICE:

Be sure to connect the connector securely.

|

(i) w/ Clearance Warning System: (1) Connect the 5 connectors. |

|

(j) w/o Clearance Warning System:

(1) Connect the 4 connectors.

(k) Attach the 2 wire harness clamps.

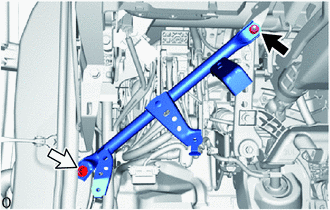

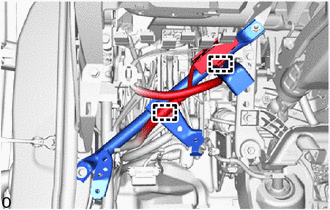

3. INSTALL NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY (for TMC Made)

(a) Install the No. 3 instrument panel to cowl brace sub-assembly with the nut and bolt.

|

Nut |

|

Bolt |

Torque:

Nut :

10 N·m {102 kgf·cm, 7 ft·lbf}

Bolt :

10 N·m {102 kgf·cm, 7 ft·lbf}

|

(b) Attach the 2 wire harness clamps. |

|

4. INSTALL CENTER INSTRUMENT PANEL BRACKET SUB-ASSEMBLY (for TMMC Made)

HINT:

Use the same procedure described as for the No. 3 instrument panel to cowl brace sub-assembly (for TMC Made).

5. INSTALL LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

6. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

7. INSTALL BATTERY HOLE COVER (for HV Model)

8. INSTALL REAR NO. 2 FLOOR BOARD (for HV Model)

9. INSTALL DECK BOARD ASSEMBLY (for HV Model)

10. PERFORM DIAGNOSTIC SYSTEM CHECK

11. CHECK SRS WARNING LIGHT

|

|

|

![2019 - 2020 MY RAV4 RAV4 HV [11/2018 - 08/2020]; SUPPLEMENTAL RESTRAINT SYSTEMS: KNEE AIRBAG ASSEMBLY: INSTALLATION](/t3Portal/stylegraphics/info.gif)