| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001EXIU |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - 02/2019] |

| Title: PARKING BRAKE: ELECTRIC PARKING BRAKE SYSTEM (w/o Vacuum Brake Booster): C13A6; Open or Short Circuit in Motor; 2019 MY RAV4 RAV4 HV [11/2018 - 02/2019] | ||

|

DTC |

C13A6 |

Open or Short Circuit in Motor |

DESCRIPTION

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Memory |

Note |

|---|---|---|---|---|---|

|

C13A6 |

Open or Short Circuit in Motor |

One of the following conditions are met: Detection conditions (1)

Detection conditions (2)

Detection conditions (3)

|

|

Yes |

An electric parking brake system malfunction is displayed on the multi-information display. |

DTC Detection Condition Combination Table: C13A6

|

Vehicle Condition |

|||||

|

Pattern 1 |

Pattern 2 |

Pattern 3 |

Pattern 4 |

||

|

Diagnosis Condition |

Electric parking brake switch (integration control and panel assembly) is operated to lock side with power switch off |

○ |

- |

- |

- |

|

Power switch on (IG) |

- |

○ |

- |

- |

|

|

Power switch off |

- |

- |

○ |

- |

|

|

With the power switch on (IG) and an overcurrent malfunction being continuously detected, the parking brake is locked and released |

- |

- |

- |

○ |

|

|

Malfunction Status |

Parking brake motor circuit malfunction when power supply voltage and +B voltage are normal |

○ |

○ |

- |

- |

|

An overcurrent malfunction is continuously detected |

- |

- |

○ |

- |

|

|

Detection Time |

Approximately 1 to 2 seconds |

Approximately 1 to 2 seconds |

1 second or more |

3 times |

|

|

Trip Count |

1 trip |

1 trip |

1 trip |

1 trip |

|

HINT:

If the conditions match either of these patterns, a DTC will be output.

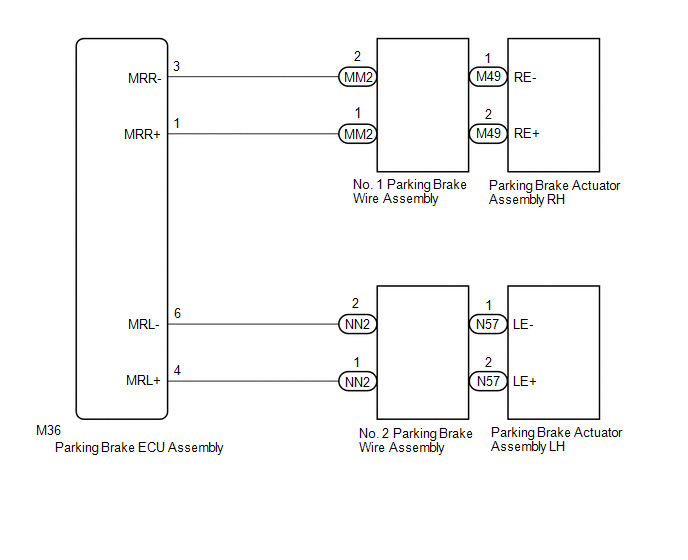

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- The electric parking brake may still operate up to 20 seconds after the power switch is turned off. Before disconnecting connectors or fuses, turn the power switch off and wait 20 seconds or more.

- When replacing the parking brake ECU assembly, operate the electric parking brake switch (integration control and panel assembly) from the lock side to the release side, as the parking brake indicator light blinks when the power switch is first turned on (IG).

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (RH ACTUATOR CURRENT STATUS / LH ACTUATOR CURRENT STATUS) |

(a) Turn the power switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the power switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Electric Parking Brake / Data List.

(f) Read the Data List according to the display on the Techstream.

Chassis > Electric Parking Brake > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

RH Actuator Current Status |

RH Actuator Current Status |

Valid or Inval |

Valid |

- |

|

LH Actuator Current Status |

LH Actuator Current Status |

Valid or Inval |

Valid |

- |

Chassis > Electric Parking Brake > Data List

|

Tester Display |

|---|

|

RH Actuator Current Status |

|

LH Actuator Current Status |

|

|

2. |

INSPECT PARKING BRAKE WIRE ASSEMBLY |

|

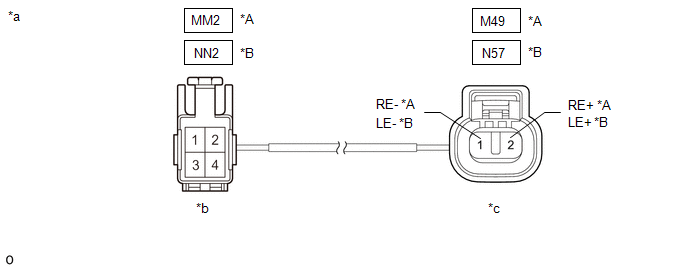

*A |

RH |

*B |

LH |

|

*a |

Front view of Parking Brake Wire Assembly |

*b |

(to Wire Harness Connector) |

|

*c |

(to Parking Brake Actuator Assembly) |

- |

- |

(a) Remove the parking brake wire assembly.

(b) Check the parking brake wire assembly for damage.

OK:

No damage.

HINT:

If damaged, there may be a short in the wire harness or a short to ground.

(c) Inspect the parking brake wire assembly.

Standard Resistance:

RH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

MM2-2 - M49-1 (RE-) |

Always |

Below 1 Ω |

|

MM2-2 - M49-2 (RE+) |

Always |

10 kΩ or higher |

|

MM2-2 or M49-1 (RE-) - Body ground |

Always |

10 kΩ or higher |

|

MM2-1 - M49-2 (RE+) |

Always |

Below 1 Ω |

|

MM2-1 - M49-1 (RE-) |

Always |

10 kΩ or higher |

|

MM2-1 or M49-2 (RE+) - Body ground |

Always |

10 kΩ or higher |

LH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

NN2-2 - N57-1 (LE-) |

Always |

Below 1 Ω |

|

NN2-2 - N57-2 (LE+) |

Always |

10 kΩ or higher |

|

NN2-2 or N57-1 (LE-) - Body ground |

Always |

10 kΩ or higher |

|

NN2-1 - N57-2 (LE+) |

Always |

Below 1 Ω |

|

NN2-1 - N57-1 (LE-) |

Always |

10 kΩ or higher |

|

NN2-1 or N57-2 (LE+) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPLACE PARKING BRAKE WIRE ASSEMBLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (PARKING BRAKE ECU ASSEMBLY - PARKING BRAKE ACTUATOR ASSEMBLY) |

(a) Turn the power switch off.

(b) Make sure the parking brake wire assembly is securely installed.

(c) Disconnect the M36 parking brake ECU assembly connector.

(d) Disconnect the M49 or N57 parking brake actuator assembly connector.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

RH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M36-1 (MRR+) - M49-2 (RE+) |

Always |

Below 1 Ω |

|

M36-3 (MRR-) - M49-1 (RE-) |

Always |

Below 1 Ω |

|

M36-1 (MRR+) or M49-2 (RE+) - Body ground |

Always |

10 kΩ or higher |

|

M36-3 (MRR-) or M49-1 (RE-) - Body ground |

Always |

10 kΩ or higher |

LH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M36-4 (MRL+) - N57-2 (LE+) |

Always |

Below 1 Ω |

|

M36-6 (MRL-) - N57-1 (LE-) |

Always |

Below 1 Ω |

|

M36-4 (MRL+) or N57-2 (LE+) - Body ground |

Always |

10 kΩ or higher |

|

M36-6 (MRL-) or N57-1 (LE-) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT PARKING BRAKE ACTUATOR ASSEMBLY |

(a) Remove the parking brake actuator assembly.

(b) Inspect the parking brake actuator assembly.

| OK |

|

| NG |

|

|

|

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; PARKING BRAKE: ELECTRIC PARKING BRAKE ACTUATOR: REMOVAL](/t3Portal/stylegraphics/info.gif)