|

Last Modified: 01-30-2024 |

6.11:8.1.0 |

Doc ID: RM100000001F70X |

|

Model Year Start: 2019 |

Model: RAV4 |

Prod Date Range: [11/2018 - 10/2019] |

|

Title: A25A-FKS (COOLING): FLOW SHUTTING VALVE(for Heater): REMOVAL; 2019 MY RAV4 [11/2018 - 10/2019] |

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during flow shutting valve (water by-pass hose assembly) removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure

|

Necessary Procedure

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Link

|

|

Battery terminal is disconnected/reconnected

|

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes)

|

Stop and start system

|

![2019 - 2021 MY RAV4 [11/2018 - 12/2021]; STOP AND START: STOP AND START SYSTEM: PRECAUTION](/t3Portal/stylegraphics/info.gif)

|

|

Perform steering sensor zero point calibration

|

Lane control system

|

![2019 - 2021 MY RAV4 RAV4 HV [11/2018 - 12/2021]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Parking support brake system (for Gasoline model)*

|

|

Pre-collision System

|

|

Memorize steering angle neutral point

|

Parking assist monitor system

|

![2019 - 2022 MY RAV4 RAV4 HV [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PARKING ASSIST MONITOR SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Panoramic view monitor system (for Gasoline Model)

|

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PANORAMIC VIEW MONITOR SYSTEM (for Gasoline Model): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Reset back door close position

|

Power back door system (for Gasoline model)

|

![2019 - 2023 MY RAV4 [11/2018 - 10/2023]; DOOR / HATCH: POWER BACK DOOR SYSTEM (for Gasoline Model): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Back door lock initialization

|

Power door lock control system

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; DOOR LOCK: POWER DOOR LOCK CONTROL SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM

|

Perform Vehicle Identification Number (VIN) or frame number registration

|

DTC P063051 is output

|

w/ Canister Pump Module:

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (ENGINE CONTROL): SFI SYSTEM (w/ Canister Pump Module): REGISTRATION](/t3Portal/stylegraphics/info.gif)

w/o Canister Pump Module:

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (ENGINE CONTROL): SFI SYSTEM (w/o Canister Pump Module): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Code registration

|

Engine start function

|

w/ Smart Key System:

![2019 MY RAV4 [11/2018 - 10/2019]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): REGISTRATION](/t3Portal/stylegraphics/info.gif)

w/o Smart Key System:

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; THEFT DETERRENT / KEYLESS ENTRY: IMMOBILISER SYSTEM (for Gasoline Model without Smart Key System): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for UB80E:

-

If transaxle compensation code read from ECM

-

Perform reset memory

-

Transfer transaxle compensation code

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

for Initialization:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for Registration:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for UB80E:

-

If transaxle compensation code not read from ECM

-

Perform reset memory

-

Reset transaxle compensation code

-

Perform road test to allow ECM to learn

|

for UB80F:

-

If transaxle compensation code read from ECM

-

Perform reset memory

-

Transfer transaxle compensation code

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

for Initialization:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for Registration:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for UB80F:

-

If transaxle compensation code not read from ECM

-

Perform reset memory

-

Reset transaxle compensation code

-

Perform road test to allow ECM to learn

|

NOTICE:

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Battery Terminal

|

System Name

|

See Procedure

|

|

Vehicle enrolled in Toyota Entune system or safety connect system

|

6 minutes

|

|

Vehicle not enrolled in Toyota Entune system and safety connect system

|

1 minute

|

PROCEDURE

1. REMOVE FLOW SHUTTING VALVE (NO. 1 WATER BY-PASS HOSE)

Click here

![2019 MY RAV4 [11/2018 - 10/2019]; A25A-FKS (COOLING): FLOW SHUTTING VALVE (for ATF): REMOVAL](/t3Portal/stylegraphics/info.gif)

2. REMOVE FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY)

|

(a) Detach the 2 clamps and disconnect the vacuum hose from the engine wire harness.

|

|

|

(b) Disconnect the 3 connectors.

|

|

(c) Detach the clamp and disconnect the engine wire harness from the water hose clamp bracket.

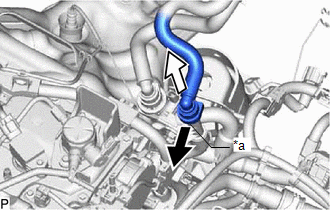

(d) Disconnect the outlet heater water hose connector from the No. 2 water by-pass pipe sub-assembly.

NOTICE:

Remove any foreign matter on the No. 2 water by-pass pipe sub-assembly and outlet heater water hose connector before performing this work.

(1) Pull out the retainer to detach the lock claws and pull off the outlet heater water hose connector.

|

*a

|

Retainer

|

|

Pull out

|

|

Pull off

|

(2) Check that there is no foreign matter on the sealing surfaces of the disconnected water lines. Clean them if necessary.

(3) Cover the disconnected No. 2 water by-pass pipe sub-assembly and outlet heater water hose connector with plastic bags to prevent damage and contamination.

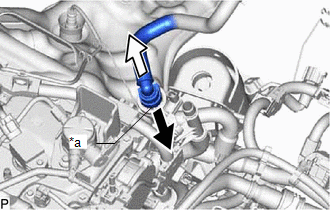

(e) Disconnect the inlet heater water hose connector from the flow shutting valve (water by-pass hose assembly).

NOTICE:

Remove any foreign matter on the flow shutting valve (water by-pass hose assembly) and inlet heater water hose connector before performing this work.

(1) Pull out the retainer to detach the lock claws and pull off the inlet heater water hose connector.

|

*a

|

Retainer

|

|

Pull out

|

|

Pull off

|

(2) Check that there is no foreign matter on the sealing surfaces of the disconnected water lines. Clean them if necessary.

(3) Cover the disconnected inlet heater water hose connector with a plastic bag to prevent damage and contamination.

|

(f) Remove the bolt to disconnect the No. 2 water by-pass pipe sub-assembly.

|

|

|

(g) Remove the bolt to disconnect the flow shutting valve (water by-pass hose assembly).

|

|

|

(h) Detach the 2 clamps and disconnect the wire harness.

|

|

|

(i) Remove the 2 bolts and the water hose clamp bracket.

|

|

|

(j) Slide the clip and disconnect the flow shutting valve (water by-pass hose assembly) from the water by-pass outlet sub-assembly.

HINT:

Use a container to catch any engine coolant which flows out of the flow shutting valve (water by-pass hose assembly) and water by-pass outlet sub-assembly.

|

|

|

(k) Slide the clip and disconnect the flow shutting valve (water by-pass hose assembly) from the transmission oil cooler.

HINT:

Use a container to catch any engine coolant which flows out of the flow shutting valve (water by-pass hose assembly) and transmission oil cooler.

|

|

|