| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001FH9A |

| Model Year Start: 2019 | Model: RAV4 HV | Prod Date Range: [11/2018 - 08/2020] |

| Title: HYBRID / BATTERY CONTROL: INVERTER WITH CONVERTER (for 2WD): INSTALLATION; 2019 - 2020 MY RAV4 HV [11/2018 - 08/2020] | ||

INSTALLATION

PROCEDURE

1. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the wire harness clamp bracket to the inverter with converter assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) Install the wire harness clamp bracket to the inverter with converter assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(c) Install the 2 wire harness clamp brackets to the inverter with converter assembly with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

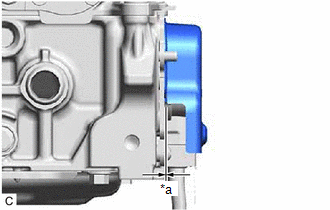

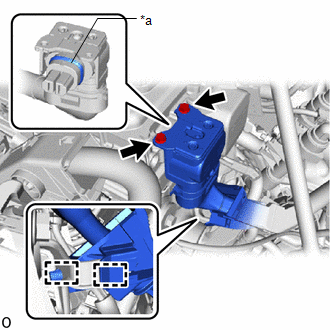

2. INSTALL NO. 2 INVERTER BRACKET

NOTICE:

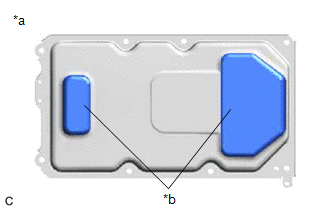

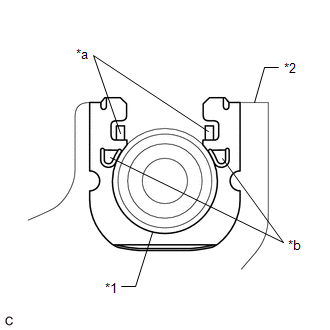

Make sure to support the inverter with converter assembly at the positions shown in the illustration, otherwise it may be damaged.

|

*a |

Bottom of Inverter with Converter Assembly |

|

*b |

Support |

|

(a) Set the inverter with converter assembly on wooden blocks. |

|

(b) Temporarily install the No. 2 inverter bracket to the inverter with converter assembly with the 2 bolts.

(c) Fully tighten the 2 bolts in the order shown in the illustration.

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

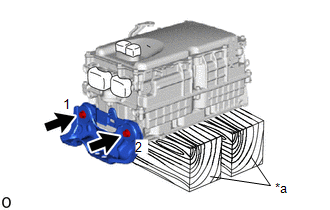

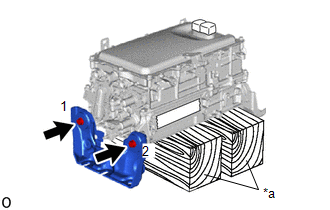

3. INSTALL NO. 1 INVERTER BRACKET

|

(a) Temporarily install the No. 1 inverter bracket to the inverter with converter assembly with the 2 bolts. |

|

(b) Fully tighten the 2 bolts in the order shown in the illustration.

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

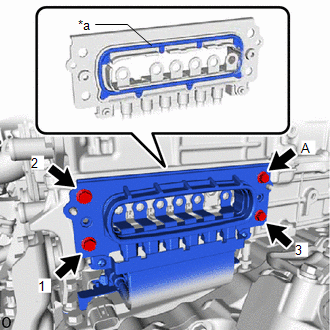

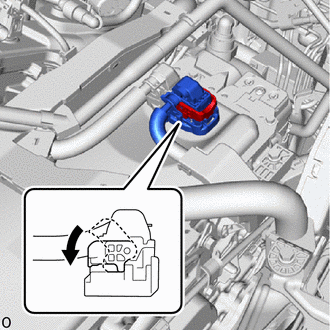

4. INSTALL INVERTER WITH CONVERTER ASSEMBLY

CAUTION:

Be sure to wear insulated gloves.

(a) Temporarily install the inverter with converter assembly with the 5 bolts and 2 nuts.

NOTICE:

- When installing the inverter with converter assembly, be careful not to damage the parts around it.

- To prevent damage, do not hold the inverter with converter assembly by the connectors, brackets or cooling pipes.

- To prevent damage due to static electricity, do not touch the terminals of the disconnected connectors.

-

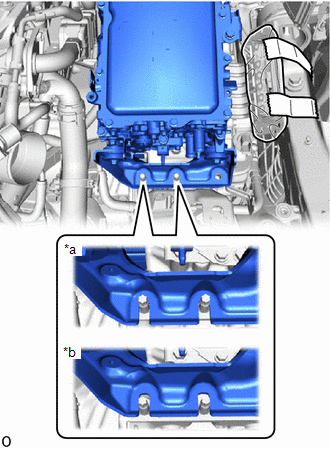

Make sure that the inverter with converter assembly is positioned so that the stud bolts are in contact with the base of the U-shaped portions of the No. 1 inverter bracket.

*a

Correct

*b

Incorrect

HINT:

If the bolts and nuts are not tightened appropriately, the inverter with converter assembly may make an abnormal noise.

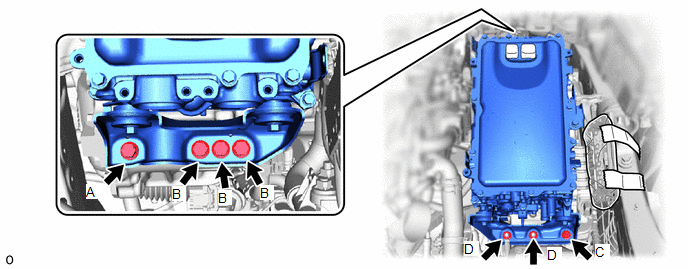

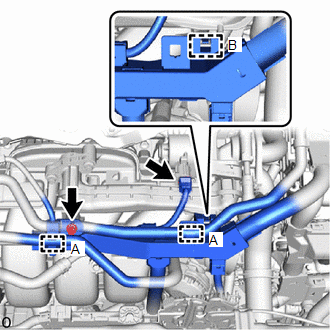

(b) Fully tighten the bolt (A).

Torque:

55 N·m {561 kgf·cm, 41 ft·lbf}

(c) Fully tighten the 3 bolts (B).

Torque:

55 N·m {561 kgf·cm, 41 ft·lbf}

(d) Fully tighten the bolt (C).

Torque:

55 N·m {561 kgf·cm, 41 ft·lbf}

(e) Fully tighten the 2 nuts (D).

Torque:

55 N·m {561 kgf·cm, 41 ft·lbf}

5. CONNECT MOTOR CABLE

CAUTION:

Be sure to wear insulated gloves.

NOTICE:

- Do not allow any foreign matter or water to enter the inverter with converter assembly.

- Adhere to the following installation procedure. Otherwise, the connector and the inverter with converter assembly may be damaged.

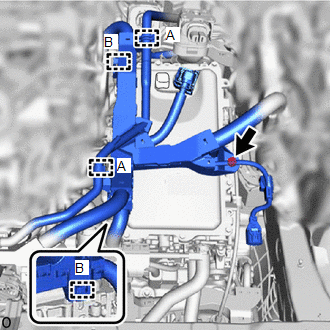

(a) Temporarily connect the motor cable to the inverter with converter assembly with the 4 bolts.

NOTICE:

- Do not touch the waterproof seal or terminals of the motor cable.

- Do not damage the terminals, connector housing or inverter with converter assembly during connection.

|

(b) Fully tighten the bolt (A). Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

(c) Fully tighten the 3 bolts in the order shown in the illustration to connect the motor cable to the inverter with converter assembly.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

|

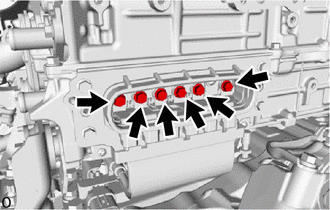

(d) Temporarily install the 6 bolts. NOTICE:

|

|

(e) Using an insulated tool, fully tighten the 6 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

NOTICE:

- Do not touch the waterproof seal or terminals of the motor cable.

- Do not damage the terminals, connector housing or inverter with converter assembly during connection.

- Be sure to use a torque wrench to tighten the bolts.

6. INSTALL INVERTER COVER

CAUTION:

Be sure to wear insulated gloves.

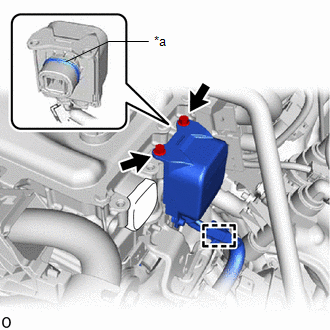

(a) Install the inverter cover to the inverter with converter assembly with the 2 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

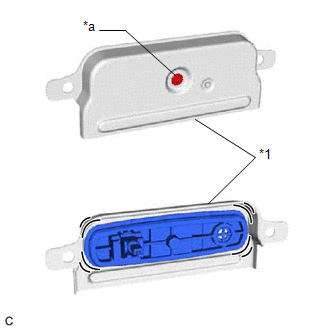

NOTICE:

- Visually confirm that the inverter cover waterproof seal is securely installed before installing the inverter cover.

- Do not touch the waterproof seal of the inverter cover.

- Make sure that the interlock is fully engaged.

- Do not damage the terminals, interlock connector or inverter with converter assembly during installation.

- Do not allow any foreign matter or water to enter the inverter with converter assembly.

-

Do not remove or excessively tighten the screw of the inverter cover.

*1

Inverter Cover

*a

Do not remove or excessively tighten the screw

- Although the inverter cover may feel loose, this is not due to a malfunction.

-

Push in the inverter cover until it contacts the inverter with converter assembly.

*a

No Gap

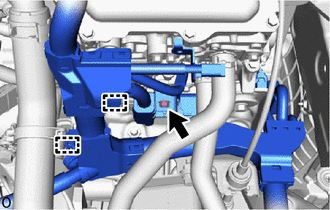

7. CONNECT NO. 4 INVERTER COOLING HOSE

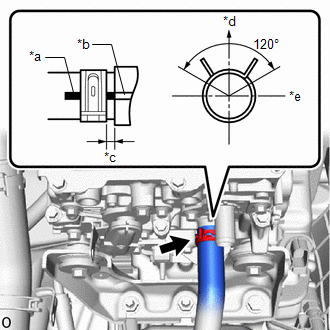

|

(a) Connect the No. 4 inverter cooling hose to the inverter with converter assembly and slide the clip to secure it. NOTICE:

HINT: Make sure that the clip is positioned as shown in the illustration. |

|

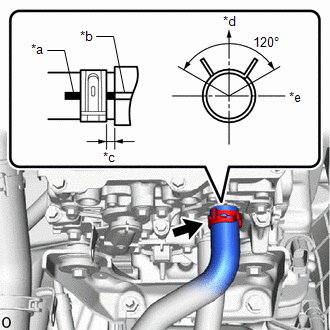

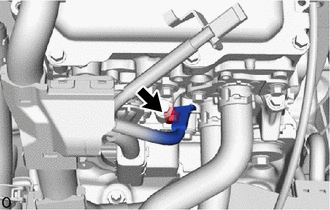

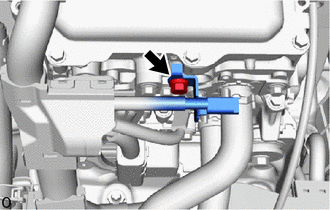

8. CONNECT NO. 1 INVERTER COOLING HOSE

|

(a) Connect the No. 1 inverter cooling hose to the inverter with converter assembly and slide the clip to secure it. NOTICE:

HINT: Make sure that the clip is positioned as shown in the illustration. |

|

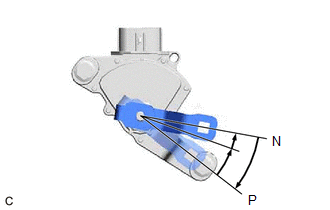

9. CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

(a) Connect the transmission control cable assembly to the inverter with converter assembly with the 3 bolts.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

|

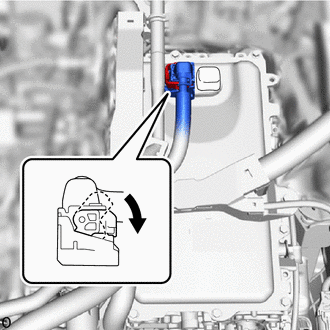

(b) Turn the control shaft lever clockwise until it stops, then turn it counterclockwise 2 notches. |

|

(c) Engage the 2 claws to install a new clip to the transmission control cable assembly.

|

(d) Using a screwdriver, engage the 4 claws and install the transmission control cable assembly to the No. 1 transmission control cable bracket. NOTICE:

|

|

(e) Connect the transmission control cable assembly to the control shaft lever with the nut.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

10. CONNECT ENGINE WIRE

CAUTION:

Be sure to wear insulated gloves.

NOTICE:

Do not allow any foreign matter or water to enter the inverter with converter assembly.

|

(a) Engage the 2 clamps and connect the engine wire to the inverter with converter assembly. |

|

(b) Temporarily install the nut.

NOTICE:

To prevent the threads from being damaged, temporarily tighten the nut by hand.

(c) Fully tighten the nut.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(d) Engage the 2 claws to close the engine wire terminal cover.

|

(e) Connect the engine wire to the inverter with converter assembly with the bolt. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

|

(f) Connect the engine wire to the inverter with converter assembly with the bolt. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

(g) Engage the 2 clamps.

(h) Engage the clamp.

(i) Confirm that no foreign matter or water has entered the connector of the generator temperature sensor, resolver (transmission fluid temperature sensor) and shift lever position sensor and connect the 3 connectors.

|

(j) Engage the clamp (B). |

|

(k) Connect the engine wire to the intake manifold with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(l) Engage the 2 clamps (A) and connect the No. 1 fuel vapor feed hose and No. 2 fuel vapor feed hose.

(m) Connect the EGR valve connector.

|

(n) Engage the 2 clamps (B). |

|

(o) Connect the engine wire to the inverter with converter assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(p) Engage the 2 clamps (A) and connect the No. 1 fuel vapor feed hose.

|

(q) Connect the inverter with converter assembly connector and move the lock lever to lock them. NOTICE:

|

|

11. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the wire harness clamp bracket to the inverter with converter assembly with the nut.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

12. CONNECT HV AIR CONDITIONING WIRE

CAUTION:

Be sure to wear insulated gloves.

|

(a) Engage the clamp and connect the HV air conditioning wire to the inverter with converter assembly. NOTICE:

|

|

(b) Install the 2 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

13. CONNECT HV FLOOR UNDER WIRE

CAUTION:

Be sure to wear insulated gloves.

|

(a) Engage the 2 clamps and connect the HV floor under wire to the inverter with converter assembly. NOTICE:

|

|

(b) Install the 2 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

14. CONNECT ENGINE ROOM MAIN WIRE

CAUTION:

Be sure to wear insulated gloves.

(a) Engage the clamp to connect the engine room main wire to the inverter with converter assembly.

(b) Install the bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

|

(c) Connect the inverter with converter assembly connector and move the lock lever to lock them. NOTICE:

|

|

15. INSTALL ECM

16. INSTALL AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE

17. INSTALL INLET AIR CLEANER ASSEMBLY

18. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

19. INSTALL SERVICE PLUG GRIP

20. ADD COOLANT (for Inverter)

21. INSPECT FOR COOLANT LEAK (for Inverter)

22. INSPECT SHIFT LEVER POSITION

23. ADJUST SHIFT LEVER POSITION

24. PERFORM INITIALIZATION

|

|

|

![2019 MY RAV4 HV [11/2018 - 02/2019]; A25A-FXS (ENGINE CONTROL): ECM: INSTALLATION](/t3Portal/stylegraphics/info.gif)