| Last Modified: 09-02-2025 | 6.11:8.1.0 | Doc ID: RM100000001FHO1 |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - ] |

| Title: A25A-FKS (FUEL): FUEL SENDER GAUGE ASSEMBLY (w/ Canister Pump Module): INSPECTION; 2019 - 2025 MY RAV4 [11/2018 - ] | ||

INSPECTION

PROCEDURE

PROCEDURE

1. INSPECT FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

(a) Check that the float moves smoothly between F and E.

(b) Check the fuel sender gauge assembly voltage.

|

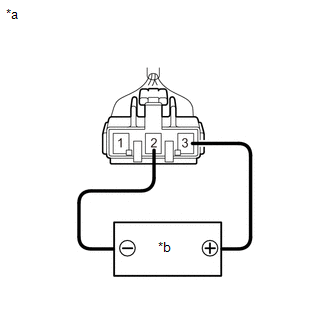

(1) Apply 5 V between terminals 2 and 3. NOTICE:

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. |

|

|

(2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

*: The output voltage changes depending on the voltage applied to the terminals. Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals) Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals) If the result is not as specified, replace the fuel sender gauge assembly. |

|

2. INSPECT NO. 2 FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

(a) Check that the float moves smoothly between F and E.

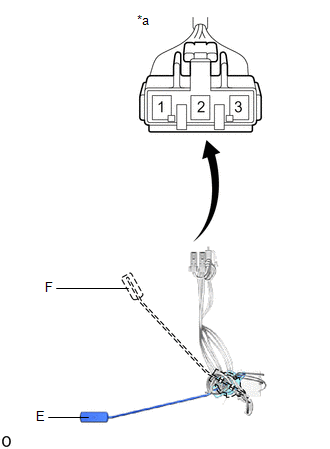

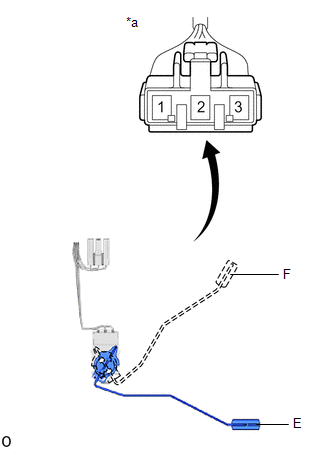

(b) Check the No. 2 fuel sender gauge assembly voltage.

|

(1) Apply 5 V between terminals 2 and 3. NOTICE:

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. |

|

|

(2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

*: The output voltage changes depending on the voltage applied to the terminals. Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals) Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals) If the result is not as specified, replace the No. 2 fuel sender gauge assembly. |

|

|

|

|