- Cooling is poor.

- Takes time to cool down.

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001FPHP |

| Model Year Start: 2019 | Model: RAV4 HV | Prod Date Range: [11/2018 - 02/2019] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM (for HV Model): Cooling is Poor; 2019 MY RAV4 HV [11/2018 - 02/2019] | ||

|

Cooling is Poor |

DESCRIPTION

If the cooling air is poor (cooling air is discharged), the following causes are possible.

|

Malfunction Status |

Factor |

|---|---|

|

|

|

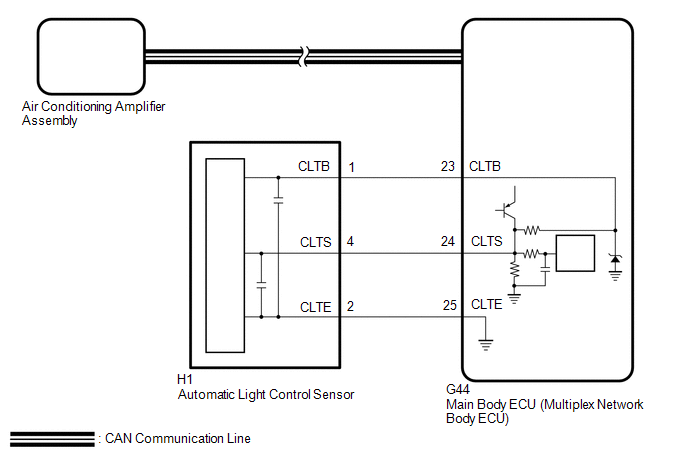

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK ECO DRIVE MODE OPERATION |

(a) Confirm setup of the ECO drive mode and turn it off if it is on.

HINT:

-

When ECO drive mode is on, the air conditioning amplifier assembly ensures a minimum level of air conditioning control based on certain conditions, thereby contributing to improved fuel efficiency. Accordingly, explain to customers that the air volume will be weaker in these situations.

Control

Control Summary

Airflow Control

Automatically switches the air inlet port to the internal air circulation mode when the outside air temperature is equal to or higher than a predetermined temperature and reduces the power consumption.

Air Inlet Control

Sets the blower level in AUTO mode lower than normal, and suppresses the power consumption.

- If integration control and panel assembly (ECO switch) is malfunctioning, perform diagnosis on the ECO switch circuit.

|

|

2. |

CHECK REFRIGERANT PRESSURE |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Regulator Pressure Sensor |

Air conditioner pressure sensor |

Min.: -456.6 kPaG (gauge) Max.: 3294.3 kPaG (gauge) |

Actual refrigerant pressure displayed |

|

Body Electrical > Air Conditioner > Data List

|

Tester Display |

|---|

|

Regulator Pressure Sensor |

(f) Install a manifold gauge set.

(g) Read the manifold gauge pressure when the following conditions are met.

(1) Prepare the vehicle according to the table below.

Measurement Condition:

|

Item |

Condition |

|---|---|

|

Vehicle Condition |

Power switch on (READY) |

|

Doors |

Fully closed (windows also fully closed) |

|

A/C Switch |

On |

|

Recirculation/fresh Control Switch |

Recirculation |

|

Set Temperature |

MAX COLD |

|

Blower Speed |

HI |

|

Air Conditioning Air Inlet Temperature |

25 to 35°C (77 to 95°F) |

Standard Pressure:

Low pressure side

150 to 250 kPa (1.5 to 2.5 kgf/cm2, 22 to 36 psi)

High pressure side

1370 to 1570 kPa (14 to 16 kgf/cm2, 199 to 228 psi)

(h) Compare the values displayed in the Data List and on the manifold gauge.

OK:

The values displayed in the Data List and on the manifold gauge match.

| NG |

|

CHARGE SYSTEM WITH REFRIGERANT |

|

|

3. |

PERFORM ACTIVE TEST USING TECHSTREAM (SERVO PULSE) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Check the operation by referring to the table below.

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Air Mix Servo Targ Pulse(D) |

No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 165 to 257 pulses |

|

Air Mix Servo Targ Pulse(P) |

No. 1 air conditioning radiator damper servo sub-assembly (front passenger side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 255 to 347 pulses |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Mix Servo Targ Pulse(D) |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Mix Servo Targ Pulse(P) |

OK:

Damper servo motor is operated.

| NG |

|

|

|

4. |

CHECK HARNESS AND CONNECTOR (AUTOMATIC LIGHT CONTROL SENSOR - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the H1 automatic light control sensor connector.

(b) Disconnect the G44 main body ECU (multiplex network body ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

H1-1 (CLTB) - G44-23 (CLTB) |

Always |

Below 1 Ω |

|

H1-2 (CLTE) - G44-25 (CLTE) |

Always |

Below 1 Ω |

|

H1-4 (CLTS) - G44-24 (CLTS) |

Always |

Below 1 Ω |

|

H1-1 (CLTB) or G44-23 (CLTB) - Other terminals and body ground |

Always |

10 kΩ or higher |

|

H1-2 (CLTE) or G44-25 (CLTE) - Other terminals and body ground |

Always |

10 kΩ or higher |

|

H1-4 (CLTS) or G44-24 (CLTS) - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT AUTOMATIC LIGHT CONTROL SENSOR |

(a) Remove the automatic light control sensor.

(b) Inspect the automatic light control sensor.

| OK |

|

| NG |

|

|

|

|

![2019 MY RAV4 HV [11/2018 - 02/2019]; HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM (for HV Model): ECO Switch Circuit](/t3Portal/stylegraphics/info.gif)