| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001FW70 |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - ] |

| Title: DOOR LOCK: POWER DOOR LOCK CONTROL SYSTEM: Only Back Door cannot be Opened; 2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ] | ||

|

Only Back Door cannot be Opened |

DESCRIPTION

The main body ECU (multiplex network body ECU) receives signals from the back door opener switch assembly. Then, the main body ECU (multiplex network body ECU) activates the back door lock motor.

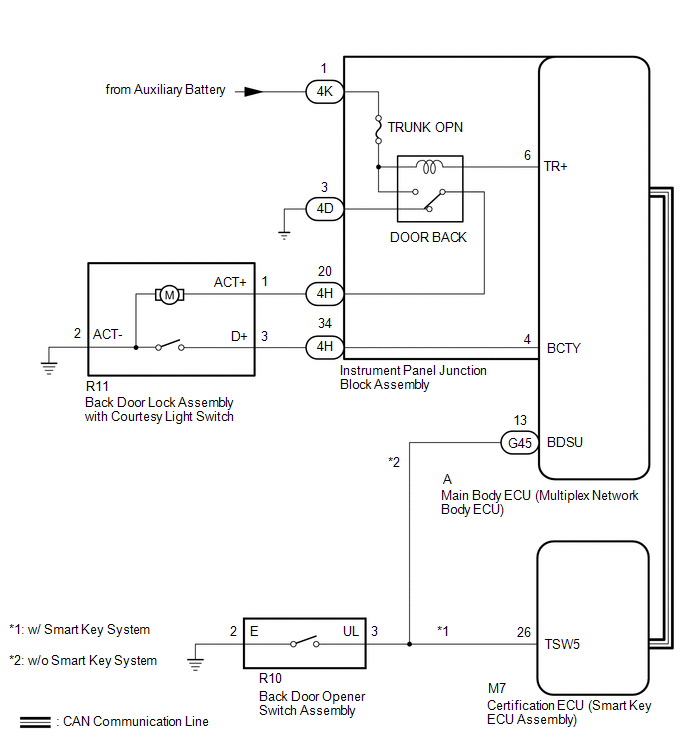

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When using the Techstream with the vehicle ignition switch off, connect the Techstream to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the Techstream and the vehicle begins.

- Inspect the fuses for circuits related to this system before performing the following procedure.

- The power door lock control system uses the CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the power door lock control system after confirming that the communication systems are functioning properly.

-

If the main body ECU (multiplex network body ECU) is replaced, refer to the Smart Key System (for start function).*

for HV Model:

for Gasoline Model:

*: w/ Smart Key System

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (Trunk and Back-Door Open) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Main Body > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Trunk and Back-Door Open |

Back door lock motor |

OFF/ON |

- |

Body Electrical > Main Body > Active Test

|

Tester Display |

|---|

|

Trunk and Back-Door Open |

OK:

The back door lock assembly with courtesy light switch unlatches when ON is selected.

|

Result |

Proceed to |

|---|---|

|

OK (w/ Entry Function) |

A |

|

OK (w/o Entry Function) |

B |

|

NG |

C |

| A |

|

GO TO SMART KEY SYSTEM (for Entry Function) for HV Model: for Gasoline Model: |

| C |

|

|

|

2. |

INSPECT BACK DOOR OPENER SWITCH ASSEMBLY |

(a) Remove the back door opener switch assembly.

(b) Inspect the back door opener switch assembly.

| NG |

|

|

|

3. |

CHECK HARNESS AND CONNECTOR (BACK DOOR OPENER SWITCH ASSEMBLY - MAIN BODY ECU [MULTIPLEX NETWORK BODY ECU] AND BODY GROUND) |

(a) Disconnect the R10 back door opener switch assembly connector.

(b) Disconnect the G45 main body ECU (multiplex network body ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R10-3 (UL) - G45-13 (BDSU) |

Always |

Below 1 Ω |

|

R10- 2 (E) - Body ground |

Always |

Below 1 Ω |

|

R10-3 (UL) or G45-13 (BDSU) - Other terminals and body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

4. |

INSPECT BACK DOOR LOCK ASSEMBLY WITH COURTESY LIGHT SWITCH |

(a) Remove the back door lock assembly with courtesy light switch.

(b) Inspect the back door lock assembly with courtesy light switch.

| NG |

|

|

|

5. |

CHECK HARNESS AND CONNECTOR (BACK DOOR LOCK ASSEMBLY WITH COURTESY LIGHT SWITCH - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY AND BODY GROUND) |

(a) Disconnect the R11 back door lock assembly with courtesy light switch connector.

(b) Disconnect the 4H instrument panel junction block assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R11-1 (ACT+) - 4H-20 |

Always |

Below 1 Ω |

|

R11-3 (D+) - 4H-34 |

Always |

Below 1 Ω |

|

R11-2 (ACT-) - Body ground |

Always |

Below 1 Ω |

|

R11-1 (ACT+) or 4H-20 - Other terminals and body ground |

Always |

10 kΩ or higher |

|

R11-3 (D+) or 4H-34 - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

(a) Remove the instrument panel junction block assembly.

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

|

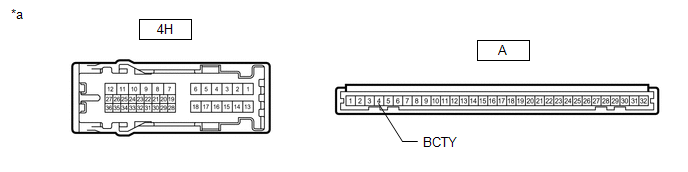

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A-4 (BCTY) - 4H-34 |

Always |

Below 1 Ω |

| NG |

|

|

|

7. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - BATTERY AND BODY GROUND) |

(a) Disconnect the instrument panel junction block assembly connectors.

|

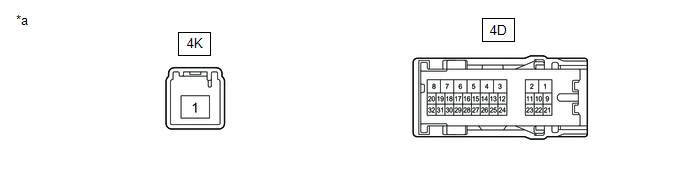

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

4K-1 - Body ground |

Ignition switch off |

11 to 14 V |

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4D-3 - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

8. |

CHECK INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY (DOOR BACK RELAY) |

(a) Remove the instrument panel junction block assembly.

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

|

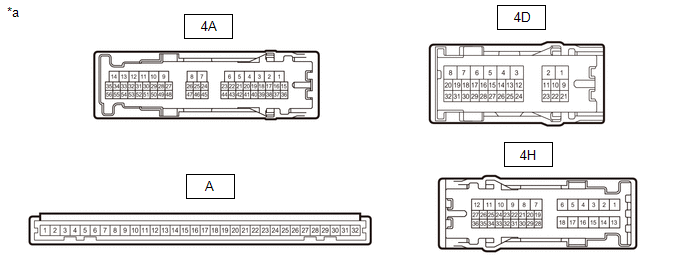

*a |

Front view of wire harness connector (to Instrument Panel Junction Block Assembly) |

- |

- |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4D-3 - 4H-20 |

Auxiliary battery voltage applied to terminals 4K-1 and A-6 |

10 kΩ or higher |

|

4D-3 - 4H-20 |

Auxiliary battery voltage not applied to terminals 4K-1 and A-6 |

Below 1 Ω |

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4H-20 - Auxiliary battery negative (-) terminal |

Auxiliary battery voltage applied to terminals 4K-1 and A-6 |

11 to 14 V |

| OK |

|

| NG |

|

|

|

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; DOOR LOCK: POWER DOOR LOCK CONTROL SYSTEM: HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)