|

Last Modified: 01-30-2024 |

6.11:8.1.0 |

Doc ID: RM100000001G20R |

|

Model Year Start: 2019 |

Model: RAV4 HV |

Prod Date Range: [11/2018 -

] |

|

Title: THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, HV Model): B2278; Engine/Power Switch Malfunction; 2019 - 2024 MY RAV4 HV [11/2018 - ] |

|

DTC

|

B2278

|

Engine/Power Switch Malfunction

|

DESCRIPTION

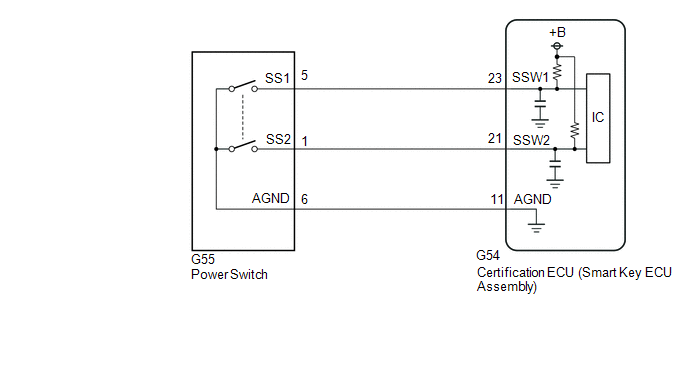

This DTC is stored when the SSW1 contact signal and SSW2 contact signal, which are detected when the power switch is operated, do not match.

|

DTC No.

|

Detection Item

|

DTC Detection Condition

|

Trouble Area

|

Note

|

|

B2278

|

Engine/Power Switch Malfunction

|

When the power switch is operated, the SSW1 contact signal and SSW2 contact signal do not match (1-trip detection logic*).

|

-

Power switch

-

Certification ECU (smart key ECU assembly)

-

Harness or connector

|

DTC Output Confirmation Operation:

-

Turn the power switch on (IG).

|

-

*: Only detected while a malfunction is present.

Vehicle Condition and Fail-safe Function when Malfunction Detected

|

Vehicle Condition when Malfunction Detected

|

Fail-safe Function when Malfunction Detected

|

|

If either the SSW1 contact signal or SSW2 contact signal is stuck on, the power source mode cannot be changed by pressing the power switch. If either the SSW1 contact signal or SSW2 contact signal is stuck off, emergency stop by pressing and holding the power switch for 2 seconds or more cannot be operated.

|

-

|

Related Data List and Active Test Items

|

DTC No.

|

Data List and Active Test

|

|

B2278

|

Power Source Control

-

Starter Switch1

-

Starter Switch2

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

PROCEDURE

|

1.

|

READ VALUE USING TECHSTREAM (START SWITCH1, START SWITCH2)

|

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Power Source Control / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Power Source Control > Data List

|

Tester Display

|

Measurement Item

|

Range

|

Normal Condition

|

Diagnostic Note

|

|

Start Switch1

|

Power switch 1 status

|

OFF or ON

|

OFF: Power switch not pressed

ON: Power switch pressed

|

-

If the power switch is pressed for a short time, the display may not change.

-

Use this item to determine if the power switch input signal is malfunctioning.

|

|

Start Switch2

|

Power switch 2 status

|

OFF or ON

|

OFF: Power switch not pressed

ON: Power switch pressed

|

-

Backup for power switch 1. However, when the power switch is pressed and held, the power source mode can only be changed when both power switch 1 and 2 are normal.

-

Behaves the same way as power switch 1.

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

|

Start Switch1

|

|

Start Switch2

|

OK:

The Techstream display changes correctly in response to the power switch operation.

|

OK

|

|

|

|

2.

|

READ VALUE USING TECHSTREAM (START SWITCH1, START SWITCH2)

|

(a) According to the display on the Techstream, read the Data List while wiggling the wire harness.

Body Electrical > Power Source Control > Data List

|

Tester Display

|

Measurement Item

|

Range

|

Normal Condition

|

Diagnostic Note

|

|

Start Switch1

|

Power switch 1 status

|

OFF or ON

|

OFF: Power switch not pressed

ON: Power switch pressed

|

-

If the power switch is pressed for a short time, the display may not change.

-

Use this item to determine if the power switch input signal is malfunctioning.

|

|

Start Switch2

|

Power switch 2 status

|

OFF or ON

|

OFF: Power switch not pressed

ON: Power switch pressed

|

-

Backup for power switch 1. However, when the power switch is pressed and held, the power source mode can only be changed when both power switch 1 and 2 are normal.

-

Behaves the same way as power switch 1.

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

|

Start Switch1

|

|

Start Switch2

|

OK:

The Data List changes for both "Start Switch1" and "Start Switch2" when the push start switch is operated while jiggling the wire harness.

| OK |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR IN CIRCUIT CONNECTED TO POWER SOURCE

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

3.

|

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - POWER SWITCH)

|

(a) Disconnect the G54 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the G55 power switch connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

G54-23 (SSW1) - G55-5 (SS1)

|

Always

|

Below 1 Ω

|

|

G54-21 (SSW2) - G55-1 (SS2)

|

Always

|

Below 1 Ω

|

|

G54-11 (AGND) - G55-6 (AGND)

|

Always

|

Below 1 Ω

|

|

G54-23 (SSW1) or G55-5 (SS1) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

G54-21 (SSW2) or G55-1 (SS2) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

G54-11 (AGND) or G55-6 (AGND) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

(a) Remove the power switch.

Click here

![2019 - 2024 MY RAV4 HV [11/2018 - ]; A25A-FXS (STARTING): POWER SWITCH: REMOVAL](/t3Portal/stylegraphics/info.gif)

(b) Inspect the power switch.

Click here

![2019 - 2024 MY RAV4 HV [11/2018 - ]; A25A-FXS (STARTING): POWER SWITCH: INSPECTION](/t3Portal/stylegraphics/info.gif)

|