| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001G227 |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - 08/2020] |

| Title: THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): B279986; Engine Immobiliser System Signal (Some Circuit Quantity, Reported via Serial Data) Invalid; 2019 - 2020 MY RAV4 [11/2018 - 08/2020] | ||

|

DTC |

B279986 |

Engine Immobiliser System Signal (Some Circuit Quantity, Reported via Serial Data) Invalid |

DESCRIPTION

w/o Occupant Classification System:

- If there is a communication malfunction between the ECM and ID code box (immobiliser code ECU), or when the communication ID codes do not match, the ECM stores this DTC.

w/ Occupant Classification System:

- If there is a communication malfunction between the ECM and certification ECU (smart key ECU assembly), or when the communication ID codes do not match, the ECM stores this DTC.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Note |

|---|---|---|---|---|

|

B279986 |

Engine Immobiliser System Signal (Some Circuit Quantity, Reported via Serial Data) Invalid |

Either of the following conditions is met (1 trip detection logic*): w/o Occupant Classification System:

w/ Occupant Classification System:

|

w/o Occupant Classification System

w/ Occupant Classification System

|

DTC output confirmation operation (Perform either of the following):

|

- *: Only output while a malfunction is present.

Vehicle Condition and Fail-safe Operation when Malfunction Detected

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

Engine cannot be started |

- |

Related Data List and Active Test

|

DTC No. |

Data List and Active Test |

|---|---|

|

B279986 |

- |

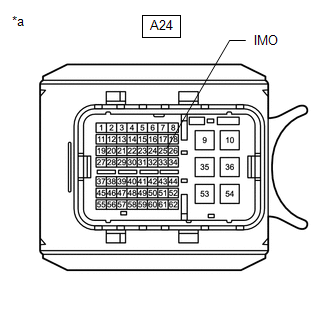

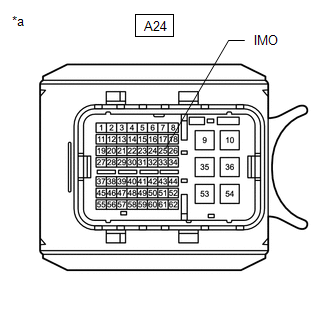

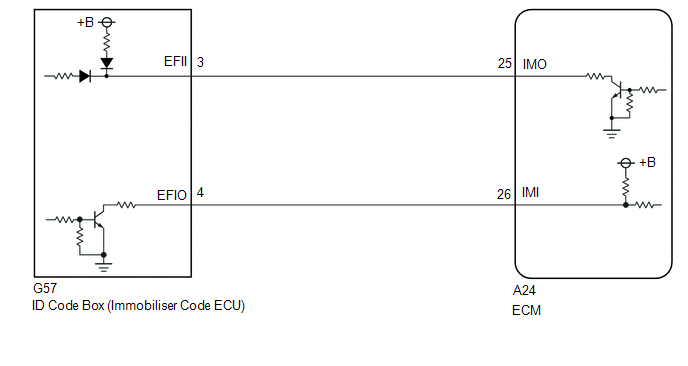

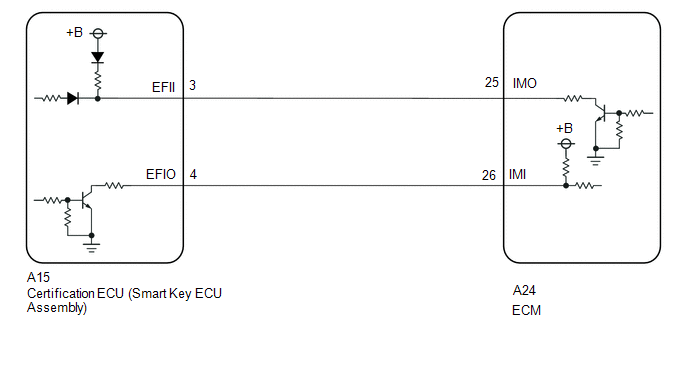

WIRING DIAGRAM

w/o Occupant Classification System:

w/ Occupant Classification System:

CAUTION / NOTICE / HINT

NOTICE:

- When using the Techstream with the engine switch off, connect the Techstream to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the Techstream and the vehicle begins. Then select the vehicle type under manual mode and enter the following menus: Body Electrical / Smart Key. While using the Techstream, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the Techstream and the vehicle.

- The smart key system (for Start Function) uses the LIN communication system and CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the smart key system (for Start Function) after confirming that the communication systems are functioning properly.

- Before replacing the ECM, ID code box (immobiliser code ECU)*1 or certification ECU (smart key ECU assembly)*2, refer to the Registration.

-

After repair, confirm that no DTCs are output by performing "DTC Output Confirmation Operation".

- *1: w/o Occupant Classification System

- *2: w/ Occupant Classification System

HINT:

When DTC B279986 and a certification ECU (smart key ECU assembly) DTC are output simultaneously, first perform troubleshooting for the certification ECU (smart key ECU assembly) DTC.

PROCEDURE

|

1. |

CHECK VEHICLE TYPE |

(a) Check vehicle condition.

| w/ Occupant Classification System |

|

|

|

2. |

REGISTER ECU COMMUNICATION ID (ID CODE BOX (IMMOBILISER CODE ECU) - ECM) |

(a) Register the communication ID codes.

HINT:

Refer to Registration.

|

|

3. |

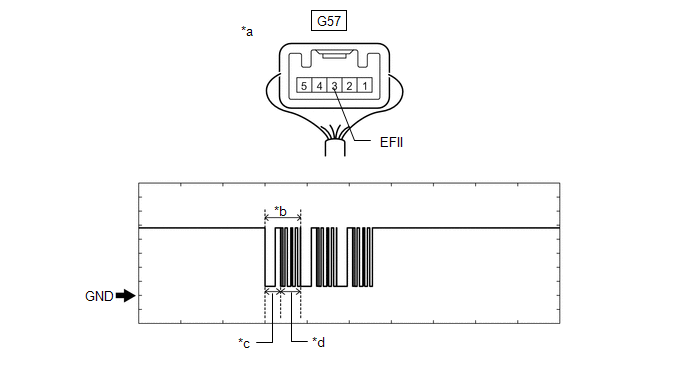

CHECK ECM (TERMINAL EFII) |

(a) Using an oscilloscope, check the waveform.

|

*a |

Component with harness connected (ID Code Box (Immobiliser Code ECU)) |

*b |

Waveform |

|

*c |

Approximately 160 ms. |

*d |

Approximately 270 ms. |

Measurement Condition:

|

Tester Connection |

Condition |

Tool Setting |

Specified Condition |

|---|---|---|---|

|

G57-3 (EFII) - Body ground |

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform) |

|

Result |

Proceed to |

|---|---|

|

Normal waveform |

A |

|

Terminal EFII stuck low (2.4 V or less) |

B |

|

Waveform length or shape is abnormal, or EFII terminal stuck at Hi (12 V) |

C |

| B |

|

| C |

|

|

|

4. |

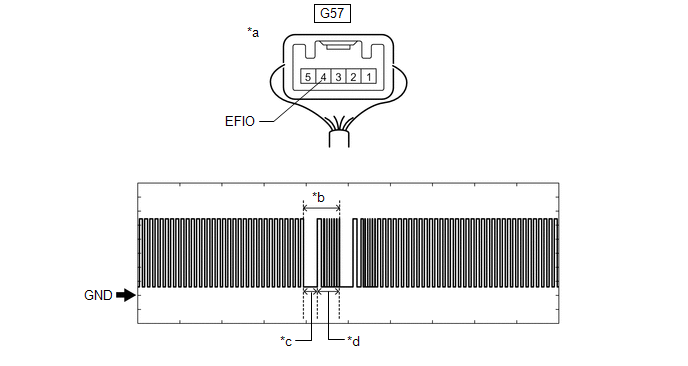

CHECK ID CODE BOX (IMMOBILISER CODE ECU) (TERMINAL EFIO) |

(a) Using an oscilloscope, check the waveform.

|

*a |

Component with harness connected (ID Code Box (Immobiliser Code ECU)) |

*b |

Waveform |

|

*c |

Approximately 160 ms. |

*d |

Approximately 270 ms. |

Measurement Condition:

|

Tester Connection |

Condition |

Tool Setting |

Specified Condition |

|---|---|---|---|

|

G57-4 (EFIO) - Body ground |

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform) |

| NG |

|

|

|

5. |

REGISTER ECU COMMUNICATION ID (ID CODE BOX (IMMOBILISER CODE ECU) - ECM) |

(a) Register the ECU communication ID codes.

HINT:

Refer to Registration.

|

|

6. |

CHECK WHETHER ENGINE STARTS |

(a) Check that the engine starts.

|

Result |

Proceed to |

|---|---|

|

Engine was started |

A |

|

Engine was not started |

B |

| A |

|

END (ECU COMMUNICATION ID HAS NOT BEEN REGISTERED) |

| B |

|

|

7. |

CHECK ECM (TERMINAL IMO) |

|

(a) Disconnect the ECM connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A24-25 (IMO) - Body ground |

Engine switch turned on (IG) using registered electrical key transmitter sub-assembly |

Terminal IMO stuck low (2.4 V or less) |

|

Terminal IMO stuck high (12 V) |

|

Result |

Proceed to |

|---|---|

|

Terminal IMO stuck low (2.4 V or less) |

A |

|

Terminal IMO stuck high (12 V) |

B |

| B |

|

|

|

8. |

CHECK HARNESS AND CONNECTOR (ID CODE BOX (IMMOBILISER CODE ECU) - ECM) |

(a) Disconnect the G57 ID code box (immobiliser code ECU) connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G57-3 (EFII) - A24-25 (IMO) |

Always |

Below 1 Ω |

|

G57-3 (EFII) or A24-25 (IMO) - Other terminals and body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

9. |

REGISTER ECU COMMUNICATION ID (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ECM) |

(a) Register the communication ID codes.

HINT:

Refer to Registration.

|

|

10. |

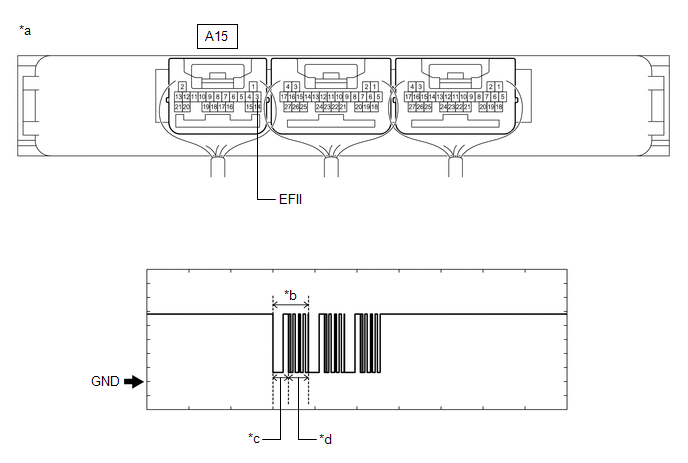

CHECK ECM (TERMINAL EFII) |

(a) Using an oscilloscope, check the waveform.

|

*a |

Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

*b |

Waveform |

|

*c |

Approximately 160 ms. |

*d |

Approximately 270 ms. |

Measurement Condition:

|

Tester Connection |

Condition |

Tool Setting |

Specified Condition |

|---|---|---|---|

|

A15-3 (EFII) - Body ground |

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform) |

|

Result |

Proceed to |

|---|---|

|

Normal waveform |

A |

|

Terminal EFII stuck low (2.4 V or less) |

B |

|

Waveform length or shape is abnormal, or EFII terminal stuck at Hi (12 V) |

C |

| B |

|

| C |

|

|

|

11. |

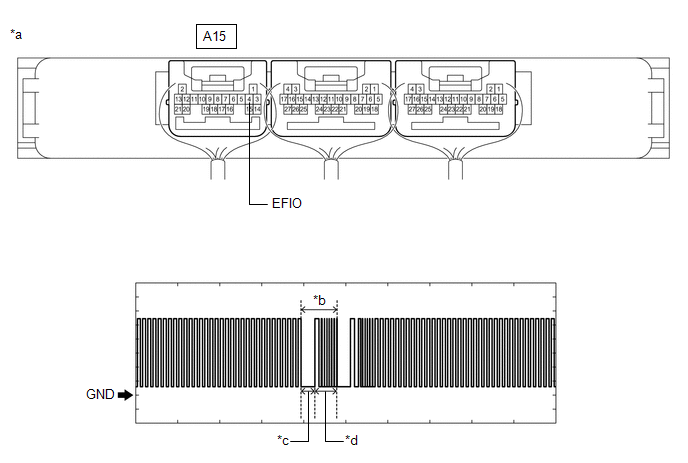

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (TERMINAL EFIO) |

(a) Using an oscilloscope, check the waveform.

|

*a |

Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

*b |

Waveform |

|

*c |

Approximately 160 ms. |

*d |

Approximately 270 ms. |

OK:

|

Tester Connection |

Condition |

Tool Setting |

Specified Condition |

|---|---|---|---|

|

A15-4 (EFIO) - Body ground |

Engine switch turned on (IG) using registered electrical key transmitter sub-assembly |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform) |

| NG |

|

|

|

12. |

REGISTER ECU COMMUNICATION ID |

(a) Register the ECU communication ID code.

HINT:

Refer to Registration.

|

|

13. |

CHECK WHETHER ENGINE STARTS |

(a) Check that the engine starts.

|

Result |

Proceed to |

|---|---|

|

Engine was started |

A |

|

Engine was not started |

B |

| A |

|

END (ECU COMMUNICATION ID HAS NOT BEEN REGISTERED) |

| B |

|

|

14. |

CHECK ECM (TERMINAL IMO) |

|

(a) Disconnect the ECM connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A24-25 (IMO) - Body ground |

Engine switch turned on (IG) using registered electrical key transmitter sub-assembly |

Terminal IMO stuck low (2.4 V or less) |

|

Terminal IMO stuck high (12 V) |

|

Result |

Proceed to |

|---|---|

|

Terminal IMO stuck low (2.4 V or less) |

A |

|

Terminal IMO stuck high (12 V) |

B |

| B |

|

|

|

15. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ECM) |

(a) Disconnect the A15 certification ECU (smart key ECU assembly) connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A15-3 (EFII) - A24-25 (IMO) |

Always |

Below 1 Ω |

|

A15-3 (EFII) or A24-25 (IMO) - Other terminals and body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)