|

Last Modified: 01-30-2024 |

6.11:8.1.0 |

Doc ID: RM100000001G22E |

|

Model Year Start: 2019 |

Model: RAV4 |

Prod Date Range: [11/2018 -

] |

|

Title: THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): Power Source Mode does not Change to ON (IG and ACC); 2019 - 2024 MY RAV4 [11/2018 - ] |

|

Power Source Mode does not Change to ON (IG and ACC)

|

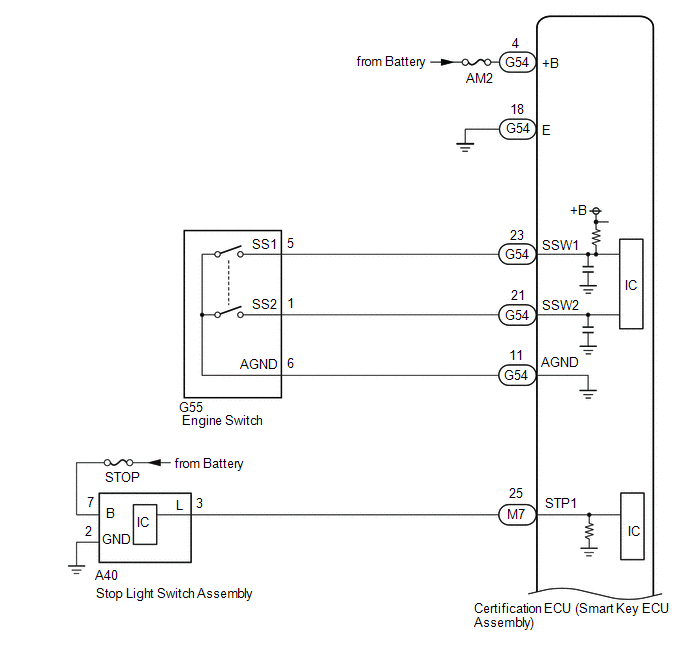

DESCRIPTION

When the engine switch cannot be turned on (ACC) or on (IG), there may be a malfunction in interior certification, or the ACC relay or IG relay system. If interior certification does not succeed, the certification ECU (smart key ECU assembly) may be malfunctioning, or communication may not be possible between the No. 1 indoor electrical key antenna assembly (front floor) or No. 2 indoor electrical key antenna assembly (rear floor), the electrical key transmitter sub-assembly, and the door control receiver.

When the electrical key transmitter sub-assembly is brought into the cabin, the key ID code sent from the electrical key transmitter sub-assembly and the key ID code stored in the certification ECU (smart key ECU assembly) are certified. If these codes do not match and certification fails, the engine switch cannot be turned on (ACC) or on (IG).

When the door is unlocked and the electrical key transmitter sub-assembly is brought into the cabin, the certification ECU (smart key ECU assembly) activates the indoor electrical key antenna and forms a detection area. When the electrical key transmitter sub-assembly is recognized inside the detection area, it returns the key ID code. This is received by the door control receiver, which then sends it to the certification ECU (smart key ECU assembly).

Related Data List and Active Test Items

|

Problem Symptom

|

Data List and Active Test

|

|

Power source mode does not change to on (IG) or on (ACC)

|

Power Source Control

-

Start Switch1

-

Start Switch2

-

IG Relay Monitor (Inside)

-

ACC Relay Monitor

-

IG Relay Monitor (Outside)

-

Latch Circuit

-

Power Supply Condition

|

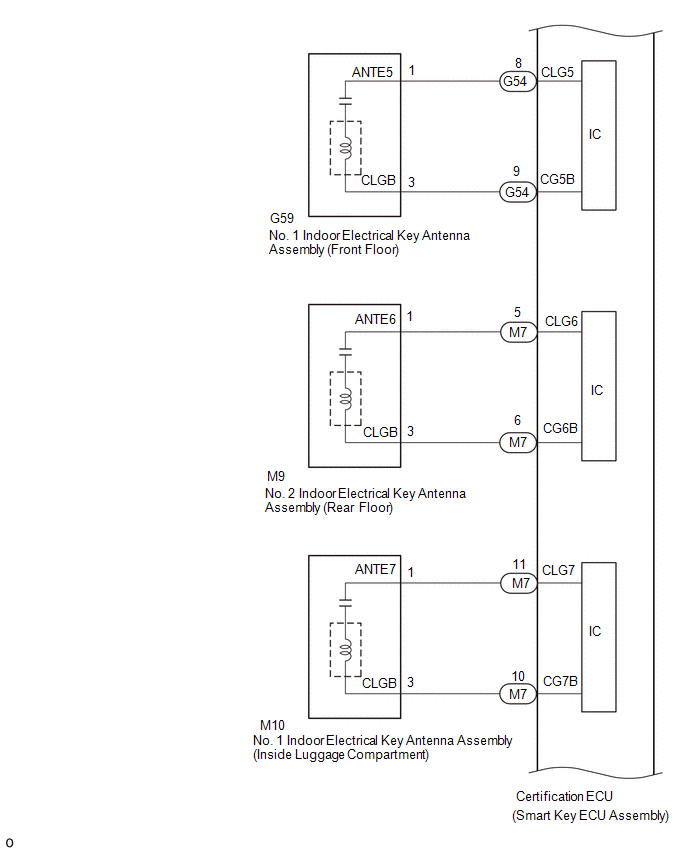

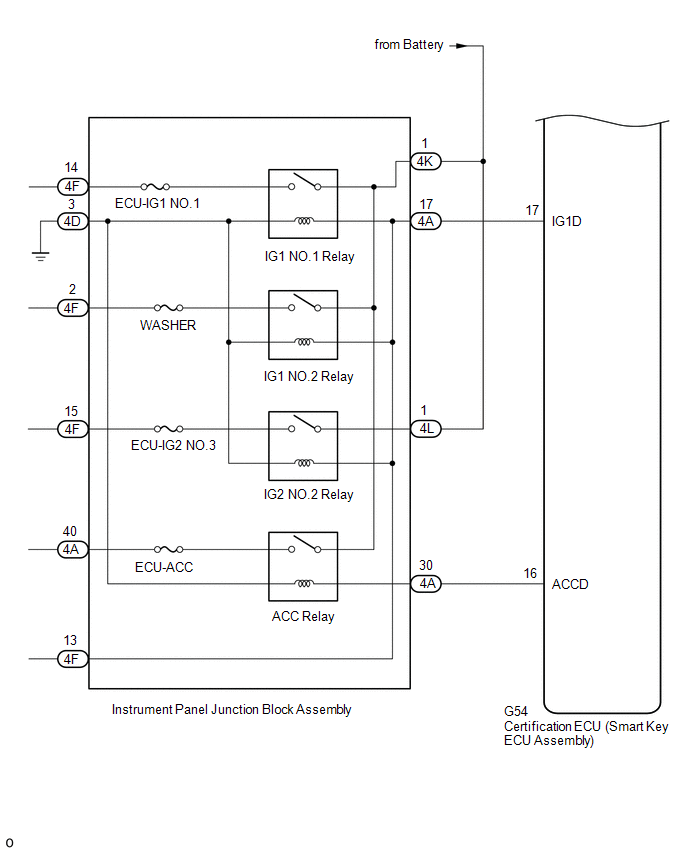

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

-

If interior certification does not succeed, the History of Reason for Operation may remain in the certification ECU (smart key ECU assembly).

-

If the operation history remains, refer to the history table to determine the conditions and narrow down any trouble areas.

Body Electrical > Smart Key > Utility

|

Tester Display

|

|

Operation History

|

PROCEDURE

|

1.

|

CHECK PUSH-BUTTON START FUNCTION

|

(a) Get into the vehicle while carrying the electrical key transmitter sub-assembly that has already been registered.

(b) Change the shift state to park (P).

(c) Check that the power source mode changes when the engine switch is pressed without depressing the brake pedal.

Click here

![2019 - 2021 MY RAV4 [11/2018 - 12/2021]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): OPERATION CHECK](/t3Portal/stylegraphics/info.gif)

![2022 - 2024 MY RAV4 [12/2021 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): OPERATION CHECK](/t3Portal/stylegraphics/info.gif)

|

Result

|

Proceed to

|

|

Power source mode does not change when the electrical key transmitter sub-assembly is inside the push-button start function operation range only for the front side

|

A

|

|

Power source mode does not change when the electrical key transmitter sub-assembly is inside the push-button start function operation range only for the rear side

|

B

|

|

Power source mode does not change when the electrical key transmitter sub-assembly is inside the push-button start function operation range only for the luggage compartment

|

C

|

|

Power source mode does not change when the electrical key transmitter sub-assembly is inside any push-button start function operation range

|

D

|

|

A

|

|

|

|

2.

|

CHECK WAVE ENVIRONMENT

|

(a) Install the transmitter battery to the electrical key transmitter sub-assembly.

Click here

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; MAINTENANCE: TRANSMITTER BATTERY(w/ Smart Key System): REMOVAL](/t3Portal/stylegraphics/info.gif)

(b) Bring the electrical key transmitter sub-assembly near the No. 1 indoor electrical key antenna assembly (front floor) and perform an smart key system check.

NOTICE:

Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the No. 1 indoor electrical key antenna assembly (front floor).

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2021 MY RAV4 [08/2020 - 12/2021]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2022 MY RAV4 [12/2021 - 10/2022]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2023 - 2024 MY RAV4 [10/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

HINT:

-

As the effect of wave interference decreases by moving the electrical key transmitter sub-assembly close to each indoor electrical key antenna assembly, it may be possible to check whether wave interference is the cause of the problem.

-

If the inspection result is that the problem only occurs in certain locations or at certain times of day, the possibility of wave interference is high. Also, added vehicle components may cause wave interference. If installed, remove them and perform the operation check.

-

There may be wave interference if the vehicle is near broadcasting antennas, large video displays, wireless garage door opener systems, wireless security cameras, home security systems, etc. In this case, move the vehicle to a different location and check if there is any improvement.

OK:

The engine starts when the electrical key transmitter sub-assembly is held near each indoor electrical key antenna assembly and the engine switch is pressed with the brake pedal depressed.

| OK |

|

AFFECTED BY WAVE INTERFERENCE

|

|

NG

|

|

|

|

3.

|

CHECK KEY DIAGNOSTIC MODE

|

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Utility / Communication Check(Key Diag Mode).

|

(e) Check the No. 1 indoor electrical key antenna assembly (front floor).

When the electrical key transmitter sub-assembly is at either inspection point, check that the buzzer sounds.

HINT:

-

Select either channel 1 or channel 2 and perform the key diagnostic mode inspection for each channel.

-

If the buzzer sounds with [CH1] displayed but not with [CH2], the electrical key transmitter sub-assembly cannot be detected by channel 2 due to a malfunction, such as wave interference.

-

It is possible to check which No. 1 indoor electrical key antenna assembly (front floor) is operating by the sounding of the buzzer.

-

When the buzzer does not sound for No. 1 indoor electrical key antenna assembly (front floor), it can be judged that the certification ECU (smart key ECU assembly), which controls the No. 1 indoor electrical key antenna assembly (front floor), is malfunctioning.

|

|

Body Electrical > Smart Key > Utility

|

Tester Display

|

|

Communication Check(Key Diag Mode)

|

|

Result

|

Proceed to

|

|

The buzzer sounds

|

A

|

|

The buzzer does not sound

|

B

|

| B |

|

AFFECTED BY WAVE INTERFERENCE

|

|

A

|

|

|

|

4.

|

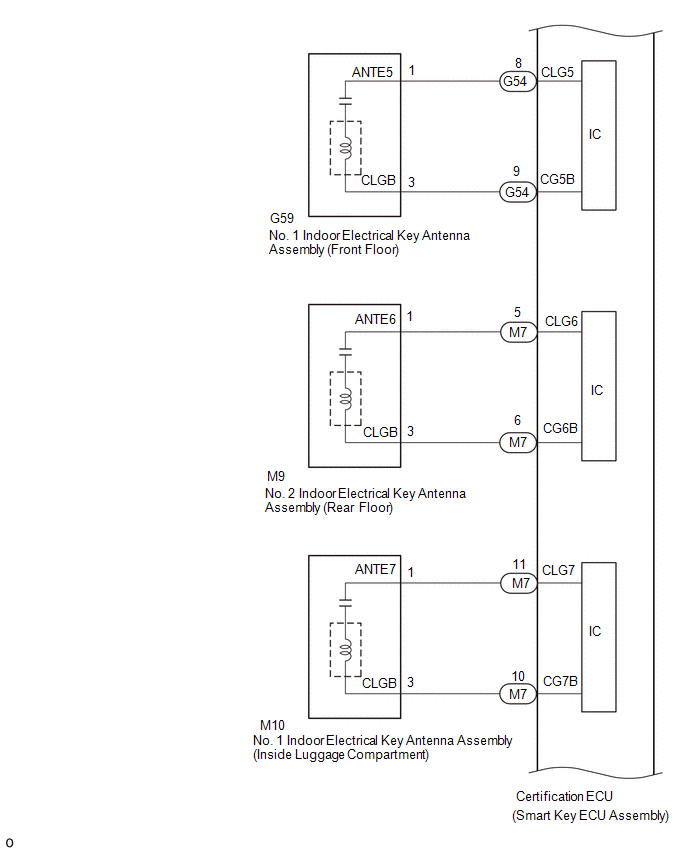

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (FRONT FLOOR))

|

(a) Disconnect the G54 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the G59 No. 1 indoor electrical key antenna assembly (front floor) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

G54-8 (CLG5) - G59-1 (ANTE5)

|

Always

|

Below 1 Ω

|

|

G54-9 (CG5B) - G59-3 (CLGB)

|

Always

|

Below 1 Ω

|

|

G54-8 (CLG5) or G59-1 (ANTE5) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

G54-9 (CG5B) or G59-3 (CLGB) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

(d) Reconnect the G54 certification ECU (smart key ECU assembly) connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

5.

|

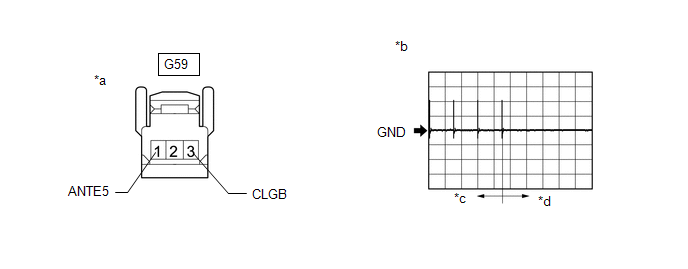

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (FRONT FLOOR))

|

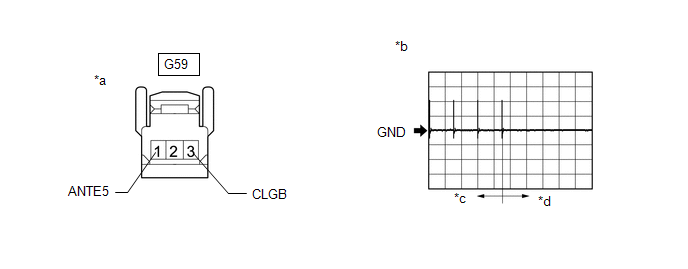

(a) Using an oscilloscope, check the waveform.

|

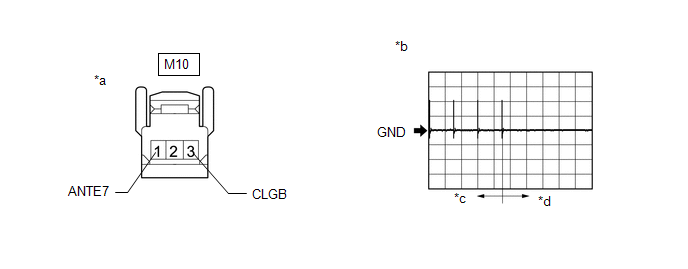

*a

|

Front view of wire harness connector

(to No. 1 Indoor Electrical Key Antenna Assembly (Front Floor))

|

*b

|

Waveform

|

|

*c

|

For 30 seconds after closing any door

|

*d

|

After 30 seconds or more have elapsed since any door closed

|

OK:

|

Tester Connection

|

Condition

|

Tool Setting

|

Specified Condition

|

|

G59-1 (ANTE5) - G59-3 (CLGB)

|

Procedure:

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

2 V/DIV., 500 ms./DIV.

|

Pulse generation

(See waveform)

|

|

6.

|

CHECK WAVE ENVIRONMENT

|

(a) Install the transmitter battery to the electrical key transmitter sub-assembly.

Click here

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; MAINTENANCE: TRANSMITTER BATTERY(w/ Smart Key System): REMOVAL](/t3Portal/stylegraphics/info.gif)

(b) Bring the electrical key transmitter sub-assembly near the No. 2 indoor electrical key antenna assembly (rear floor) and perform an smart key system check.

HINT:

Check that the customize setting "Ignition Available Area" is set to "All".

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): CUSTOMIZE PARAMETERS](/t3Portal/stylegraphics/info.gif)

![2021 - 2022 MY RAV4 [08/2020 - 10/2022]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): CUSTOMIZE PARAMETERS](/t3Portal/stylegraphics/info.gif)

![2023 - 2024 MY RAV4 [10/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): CUSTOMIZE PARAMETERS](/t3Portal/stylegraphics/info.gif)

NOTICE:

Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the center of the No. 2 indoor electrical key antenna assembly (rear floor).

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2021 MY RAV4 [08/2020 - 12/2021]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2022 MY RAV4 [12/2021 - 10/2022]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2023 - 2024 MY RAV4 [10/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

HINT:

-

As the effect of wave interference decreases by moving the electrical key transmitter sub-assembly close to each indoor electrical key antenna assembly, it may be possible to check whether wave interference is the cause of the problem.

-

If the inspection result is that the problem only occurs in certain locations or at certain times of day, the possibility of wave interference is high. Also, added vehicle components may cause wave interference. If installed, remove them and perform the operation check.

-

There may be wave interference if the vehicle is near broadcasting antennas, large video displays, wireless garage door opener systems, wireless security cameras, home security systems, etc. In this case, move the vehicle to a different location and check if there is any improvement.

OK:

The engine starts when the electrical key transmitter sub-assembly is held near each indoor electrical key antenna assembly and the engine switch is pressed with the brake pedal depressed.

| OK |

|

AFFECTED BY WAVE INTERFERENCE

|

|

NG

|

|

|

|

7.

|

CHECK KEY DIAGNOSTIC MODE

|

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Utility / Communication Check(Key Diag Mode).

|

(e) Check the No. 2 indoor electrical key antenna assembly (rear floor).

When the electrical key transmitter sub-assembly is at either inspection point, check that the buzzer sounds.

HINT:

-

Select either channel 1 or channel 2 and perform the key diagnostic mode inspection for each channel.

-

If the buzzer sounds with [CH1] displayed but not with [CH2], the electrical key transmitter sub-assembly cannot be detected by channel 2 due to a malfunction, such as wave interference.

-

It is possible to check which No. 2 indoor electrical key antenna assembly (rear floor) is operating by the sounding of the buzzer.

-

When the buzzer does not sound for No. 2 indoor electrical key antenna assembly (rear floor), it can be judged that the certification ECU (smart key ECU assembly), which controls the No. 2 indoor electrical key antenna assembly (rear floor), is malfunctioning.

|

|

Body Electrical > Smart Key > Utility

|

Tester Display

|

|

Communication Check(Key Diag Mode)

|

|

Result

|

Proceed to

|

|

The buzzer sounds

|

A

|

|

The buzzer does not sound

|

B

|

| B |

|

AFFECTED BY WAVE INTERFERENCE

|

|

A

|

|

|

|

8.

|

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - NO. 2 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (REAR FLOOR))

|

(a) Disconnect the M7 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the M9 No. 2 indoor electrical key antenna assembly (rear floor) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

M7-5 (CLG6) - M9-1 (ANTE6)

|

Always

|

Below 1 Ω

|

|

M7-6 (CG6B) - M9-3 (CLGB)

|

Always

|

Below 1 Ω

|

|

M7-5 (CLG6) or M9-1 (ANTE6) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

M7-6 (CG6B) or M9-3 (CLGB) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

(d) Reconnect the M7 certification ECU (smart key ECU assembly) connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

9.

|

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO NO. 2 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (REAR FLOOR))

|

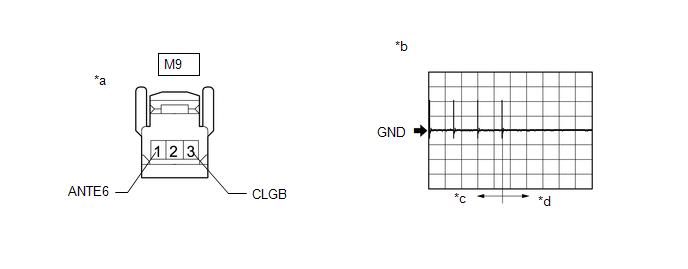

(a) Using an oscilloscope, check the waveform.

|

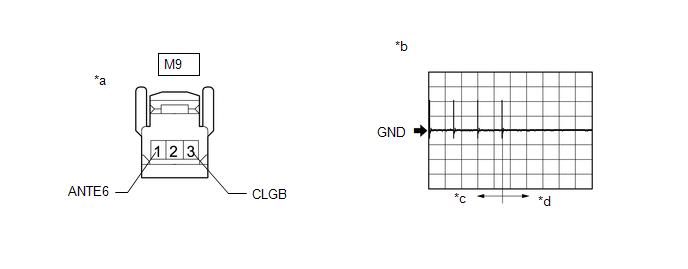

*a

|

Front view of wire harness connector

(to No. 2 Indoor Electrical Key Antenna Assembly (Rear Floor))

|

*b

|

Waveform

|

|

*c

|

For 30 seconds after closing any door

|

*d

|

After 30 seconds or more have elapsed since any door closed

|

OK:

|

Tester Connection

|

Condition

|

Tool Setting

|

Specified Condition

|

|

M9-1 (ANTE6) - M9-3 (CLGB)

|

Procedure:

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

2 V/DIV., 500 ms./DIV.

|

Pulse generation

(See waveform)

|

|

10.

|

CHECK WAVE ENVIRONMENT

|

(a) Install the transmitter battery to the electrical key transmitter sub-assembly.

Click here

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; MAINTENANCE: TRANSMITTER BATTERY(w/ Smart Key System): REMOVAL](/t3Portal/stylegraphics/info.gif)

(b) Bring the electrical key transmitter sub-assembly near the No. 1 indoor electrical key antenna assembly (inside luggage compartment) and perform an smart key system check.

HINT:

Check that the customize setting "Ignition Available Area" is set to "All".

Click here

![2019 - 2024 MY RAV4 [11/2018 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): CUSTOMER PROBLEM ANALYSIS CHECK](/t3Portal/stylegraphics/info.gif)

NOTICE:

Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the center of the No. 1 indoor electrical key antenna assembly (inside luggage compartment).

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2021 MY RAV4 [08/2020 - 12/2021]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2022 MY RAV4 [12/2021 - 10/2022]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

![2023 - 2024 MY RAV4 [10/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): PARTS LOCATION](/t3Portal/stylegraphics/info.gif)

HINT:

-

As the effect of wave interference decreases by moving the electrical key transmitter sub-assembly close to each indoor electrical key antenna assembly, it may be possible to check whether wave interference is the cause of the problem.

-

If the inspection result is that the problem only occurs in certain locations or at certain times of day, the possibility of wave interference is high. Also, added vehicle components may cause wave interference. If installed, remove them and perform the operation check.

-

There may be wave interference if the vehicle is near broadcasting antennas, large video displays, wireless garage door opener systems, wireless security cameras, home security systems, etc. In this case, move the vehicle to a different location and check if there is any improvement.

OK:

The engine starts when the electrical key transmitter sub-assembly is held near each indoor electrical key antenna assembly and the engine switch is pressed with the brake pedal depressed.

| OK |

|

AFFECTED BY WAVE INTERFERENCE

|

|

NG

|

|

|

|

11.

|

CHECK KEY DIAGNOSTIC MODE

|

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Utility / Communication Check(Key Diag Mode).

|

(e) Check the No. 1 indoor electrical key antenna assembly (inside luggage compartment).

When the electrical key transmitter sub-assembly is at either inspection point, check that the buzzer sounds.

HINT:

-

Select either channel 1 or channel 2 and perform the key diagnostic mode inspection for each channel.

-

If the buzzer sounds with [CH1] displayed but not with [CH2], the electrical key transmitter sub-assembly cannot be detected by channel 2 due to a malfunction, such as wave interference.

-

It is possible to check which No. 1 indoor electrical key antenna assembly (inside luggage compartment) is operating by the sounding of the buzzer.

-

When the buzzer does not sound for No. 2 indoor electrical key antenna assemby (rear floor), it can be judged that the certification ECU (smart key ECU assembly), which controls the No. 1 indoor electrical key antenna assembly (inside luggage compartment), is malfunctioning.

|

|

Body Electrical > Smart Key > Utility

|

Tester Display

|

|

Communication Check(Key Diag Mode)

|

|

Result

|

Proceed to

|

|

The buzzer sounds

|

A

|

|

The buzzer does not sound

|

B

|

| B |

|

AFFECTED BY WAVE INTERFERENCE

|

|

A

|

|

|

|

12.

|

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (INSIDE LUGGAGE COMPARTMENT))

|

(a) Disconnect the M7 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the M10 No. 1 indoor electrical key antenna assembly (inside luggage compartment) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

M7-11 (CLG7) - M10-1 (ANTE7)

|

Always

|

Below 1 Ω

|

|

M7-10 (CG7B) - M10-3 (CLGB)

|

Always

|

Below 1 Ω

|

|

M7-11 (CLG7) or M10-1 (ANTE7) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

M7-10 (CG7B) or M10-3 (CLGB) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

(d) Reconnect the M7 certification ECU (smart key ECU assembly) connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

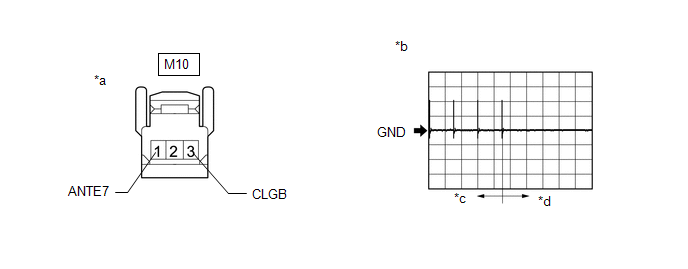

13.

|

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (INSIDE LUGGAGE COMPARTMENT))

|

(a) Using an oscilloscope, check the waveform.

|

*a

|

Front view of wire harness connector

(to No. 1 Indoor Electrical Key Antenna Assembly (Inside Luggage Compartment))

|

*b

|

Waveform

|

|

*c

|

For 30 seconds after closing any door

|

*d

|

After 30 seconds or more have elapsed since any door closed

|

OK:

|

Tester Connection

|

Condition

|

Tool Setting

|

Specified Condition

|

|

M10-1 (ANTE7) - M10-3 (CLGB)

|

Procedure:

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

2 V/DIV., 500 ms./DIV.

|

Pulse generation

(See waveform)

|

|

14.

|

CHECK TRANSMITTER BATTERY

|

(a) Check the transmitter battery level of the electrical key transmitter sub-assembly that was checked first.

(1) Press and hold the lock switch of the electrical key transmitter sub-assembly for 5 seconds and check the number of times that the LED illuminates.

|

Result

|

Proceed to

|

|

LED illuminates 3 times or more when switch is pressed and held

|

A

|

|

LED does not illuminate when switch is pressed and held

|

B

|

|

LED illuminates once or twice but not a third time

|

C

|

|

A

|

|

|

|

15.

|

CHECK ENTRY LOCK / UNLOCK FUNCTION

|

(a) Check that the entry lock and unlock functions operate on each door.

Click here

![2019 - 2023 MY RAV4 [11/2018 - 10/2023]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Entry Function, Gasoline Model): OPERATION CHECK](/t3Portal/stylegraphics/info.gif)

![2024 MY RAV4 [10/2023 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Entry Function, Gasoline Model): OPERATION CHECK](/t3Portal/stylegraphics/info.gif)

HINT:

If the door control receiver is defective, code verification does not begin in the cabin and the entry lock and unlock functions do not operate.

|

Result

|

Proceed to

|

|

Entry lock/unlock functions operate normally

|

A

|

|

An entry lock/unlock functions does not operate normally

|

B

|

|

A

|

|

|

|

16.

|

READ VALUE USING TECHSTREAM (START SWITCH1, START SWITCH2)

|

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Power Source Control / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Power Source Control > Data List

|

Tester Display

|

Measurement Item

|

Range

|

Normal Condition

|

Diagnostic Note

|

|

Start Switch1

|

Engine switch 1 status

|

OFF or ON

|

OFF: Engine switch not pressed

ON: Engine switch pressed

|

-

If the engine switch is pressed for a short time, the display may not change.

-

Use this item to determine if the engine switch input signal is malfunctioning.

|

|

Start Switch2

|

Engine switch 2 status

|

OFF or ON

|

OFF: Engine switch not pressed

ON: Engine switch pressed

|

-

Backup for engine switch 1. However, when the engine switch is pressed and held, the power source mode can only be changed when both engine switch 1 and 2 are normal.

-

Behaves the same way as engine switch 1.

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

|

Start Switch1

|

|

Start Switch2

|

OK:

The Techstream display changes correctly in response to the engine switch operation.

|

OK

|

|

|

|

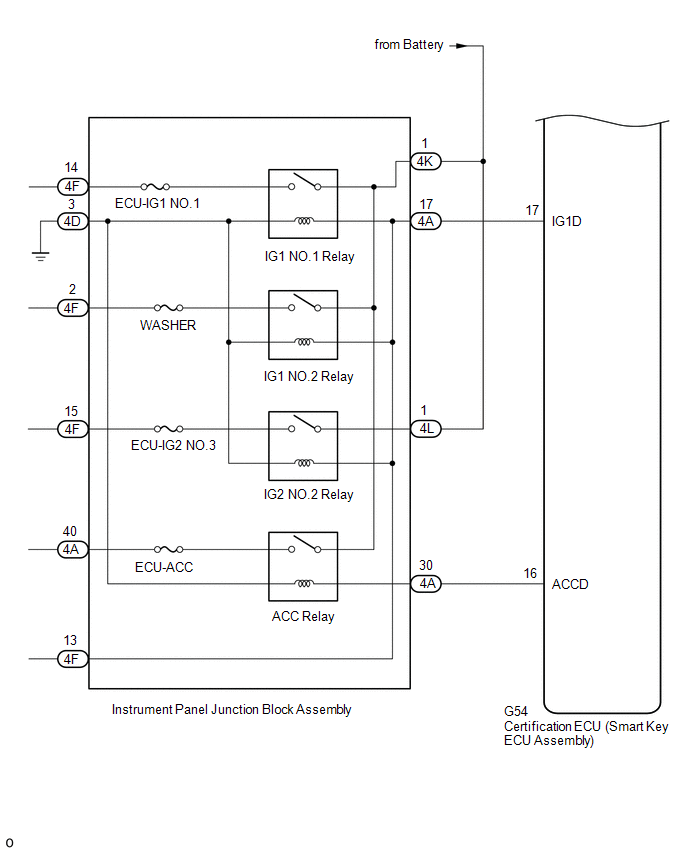

17.

|

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

|

(a) Measure the voltage while confirming the power source mode on the Data List.

|

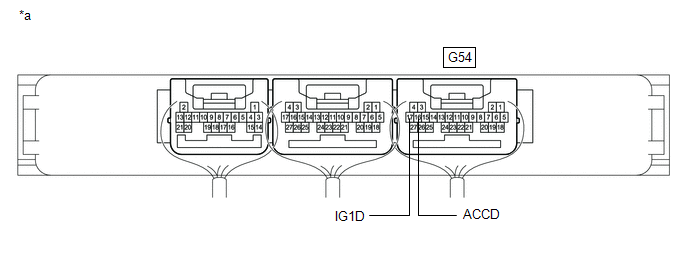

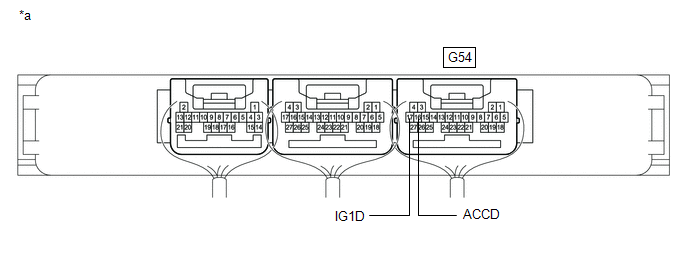

*a

|

Component with harness connected

(Certification ECU (Smart Key ECU Assembly))

|

-

|

-

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

Measurement Item

|

Range

|

Normal Condition

|

Diagnostic Note

|

|

Power Supply Condition

|

Power supply state

|

All OFF, ACC ON, IG ON or ST ON

|

All OFF: Engine switch off

ACC ON: Engine switch on (ACC)

IG ON: Engine switch on (IG)

ST ON: Sending engine start request signal

|

-

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

|

Power Supply Condition

|

Standard Voltage:

|

Tester Connection

|

Switch Condition

|

Specified Condition

|

|

G54-17 (IG1D) - Body ground

|

Engine switch off

|

1 V or less

|

|

Engine switch on (ACC)

|

|

Engine switch on (IG)

|

9 V or higher

|

|

G54-16 (ACCD) - Body ground

|

Engine switch off

|

1 V or less

|

|

Engine switch on (ACC)

|

8.5 V or higher

|

|

Engine switch on (IG)

|

|

OK

|

|

|

|

18.

|

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - BODY GROUND)

|

|

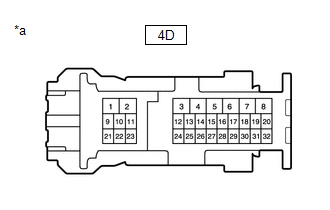

(a) Disconnect the instrument panel junction block assembly connector.

|

|

|

*a

|

Front view of wire harness connector

(to Instrument Panel Junction Block Assembly)

|

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

4D-3 - Body ground

|

Always

|

Below 1 Ω

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

19.

|

INSPECT TRANSMITTER BATTERY

|

(a) Inspect the transmitter battery.

Click here

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; DOOR LOCK: DOOR CONTROL TRANSMITTER (w/ Smart Key System): INSPECTION](/t3Portal/stylegraphics/info.gif)

NOTICE:

Do not wrap the lead wire around a terminal, wedge it between terminals, or solder it. The terminal may be deformed or damaged, and the transmitter battery will not be able to be installed correctly.

| OK |

|

REPLACE ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY

|

|

20.

|

INSPECT ENGINE SWITCH

|

(a) Remove the engine switch.

Click here

![2019 - 2024 MY RAV4 [11/2018 - ]; A25A-FKS (STARTING): ENGINE SWITCH: REMOVAL](/t3Portal/stylegraphics/info.gif)

(b) Inspect the engine switch.

Click here

![2019 - 2024 MY RAV4 [11/2018 - ]; A25A-FKS (STARTING): ENGINE SWITCH: REMOVAL](/t3Portal/stylegraphics/info.gif)

|

OK

|

|

|

|

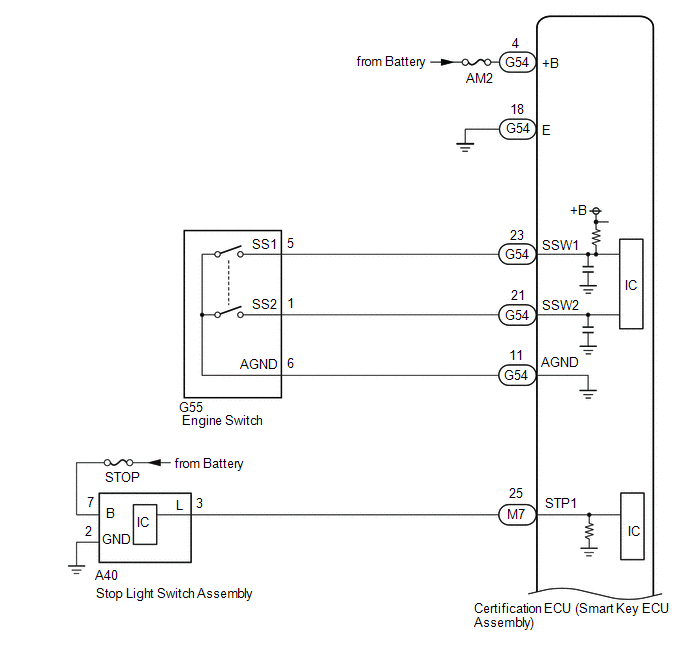

21.

|

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ENGINE SWITCH)

|

(a) Disconnect the G54 certification ECU (smart key ECU assembly) connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

G54-23 (SSW1) - G55-5 (SS1)

|

Always

|

Below 1 Ω

|

|

G54-21 (SSW2) - G55-1 (SS2)

|

Always

|

Below 1 Ω

|

|

G54-11 (AGND) - G55-6 (AGND)

|

Always

|

Below 1 Ω

|

|

G54-23 (SSW1) or G55-5 (SS1) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

G54-21 (SSW2) or G55-1 (SS2) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

G54-11 (AGND) or G55-6 (AGND) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|