- Engine assembly

- Air fuel ratio sensor (sensor 1)

- Gas leaks from exhaust system

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001H3V1 |

| Model Year Start: 2019 | Model: RAV4 HV | Prod Date Range: [02/2019 - 10/2019] |

| Title: P710 (HYBRID TRANSMISSION / TRANSAXLE): HYBRID VEHICLE TRANSAXLE: REMOVAL; 2019 MY RAV4 HV [02/2019 - 10/2019] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during hybrid vehicle transaxle assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Auxiliary battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Parking support brake system (for HV model)* |

|||

|

Pre-collision system |

|||

|

Lighting system (EXT)(w/ AFS) |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system (for HV model) |

|||

|

Reset back door close position |

Power back door system (for HV model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

ECM (w/ Canister Pump Module) |

Perform Vehicle Identification Number (VIN) registration |

DTC P063051 is output |

|

|

Grill shutter switch specification infomation |

Vehicle control history (RoB) [X260E] is stored |

||

|

ECM (w/o Canister Pump Module) |

Perform Vehicle Identification Number (VIN) registration |

DTC P063051 is output |

|

|

|

Inspection after repair |

|

|

|

Inverter with converter assembly |

Resolver learning |

|

|

|

Hybrid vehicle transaxle assembly |

|

||

|

Front bumper assembly (Including removal and installation) |

Front television camera view adjustment |

Panoramic view monitor system (for HV model) |

|

|

Suspension, tires, etc. |

Television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Panoramic view monitor system (for HV model) |

||

|

Replacement of the headlight ECU sub-assembly LH |

|

Lighting system (EXT)(w/ Headlight ECU) |

|

|

Front wheel alignment adjustment |

|

|

|

CAUTION:

-

Orange wire harnesses and connectors indicate high-voltage circuits. To prevent electric shock, always follow the procedure described in the repair manual.

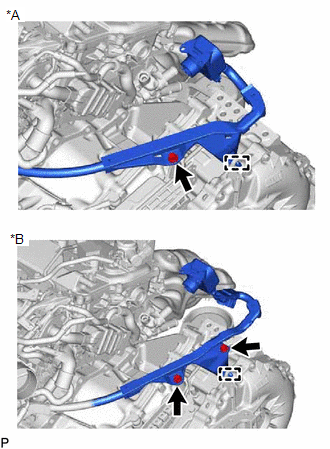

for 2WD:

for AWD:

-

To prevent electric shock, wear insulated gloves when working on wire harnesses and components of the high voltage system.

-

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

-

To prevent burns, do not touch the engine, exhaust manifold or other high temperature components while the engine is hot.

-

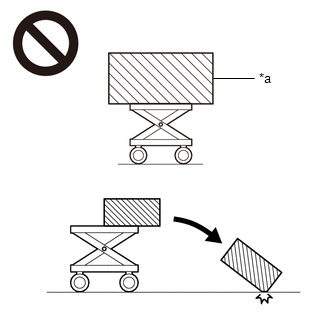

The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop or the engine assembly with transaxle may fall off the engine lifter.

*a

An Object Exceeding Weight Limit of Engine Lifter

NOTICE:

-

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) auxiliary battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Auxiliary Battery Terminal

System Name

See Procedure

Vehicle enrolled in Toyota Entune system or safety connect system

6 minutes

Vehicle not enrolled in Toyota Entune system and safety connect system

1 minute

- If the ECM has been struck or dropped, replace it.

- Perform Vehicle Identification Number (VIN) registration when replacing the ECM.

PROCEDURE

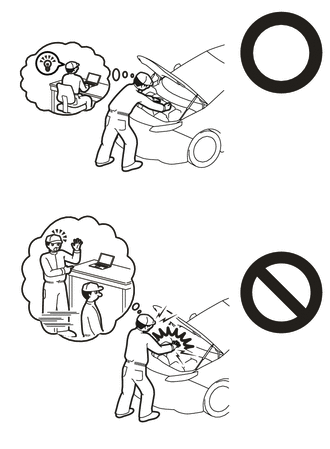

1. PERFORM RESOLVER INITIALIZATION

NOTICE:

If it is necessary to replace the hybrid vehicle transaxle assembly, make sure to perform resolver initialization before starting work.

2. REMOVE ENGINE ASSEMBLY WITH HYBRID VEHICLE TRANSAXLE ASSEMBLY

3. REMOVE FUEL DELIVERY GUARD

4. INSTALL ENGINE HANGERS

5. REMOVE STEERING GEAR HEAT INSULATOR

6. DISCONNECT WIRE HARNESS

7. DISCONNECT ENGINE WIRE

(a) Remove the 2 bolts.

(b) Disconnect the 5 clamps.

8. DISCONNECT HV AIR CONDITIONING WIRE

|

(a) for 2WD: (1) Remove the bolt. (2) Detach the guide to disconnect the HV air conditioning wire from the hybrid vehicle transaxle assembly. |

|

(b) for AWD:

(1) Remove the 2 bolts.

(2) Detach the guide to disconnect the HV air conditioning wire from the hybrid vehicle transaxle assembly.

9. REMOVE STARTER HOLE INSULATOR

|

(a) Remove the 2 bolts and starter hole insulator from the engine assembly. |

|

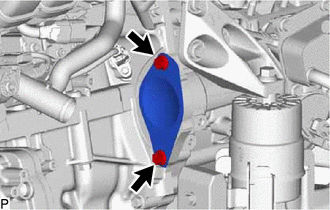

10. REMOVE FLYWHEEL HOUSING SIDE COVER

|

(a) Remove the flywheel housing side cover from the engine assembly. |

|

11. REMOVE FRONT FRAME ASSEMBLY

12. REMOVE FRONT ENGINE MOUNTING INSULATOR

|

(a) Remove the bolt and front engine mounting insulator from the transverse engine engine mounting bracket. |

|

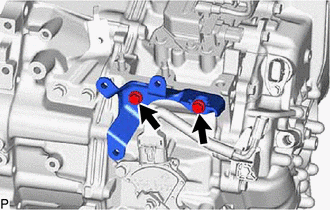

13. REMOVE TRANSVERSE ENGINE ENGINE MOUNTING BRACKET

|

(a) Remove the 3 bolts and transverse engine engine mounting bracket from the hybrid vehicle transaxle assembly. |

|

14. REMOVE REAR ENGINE MOUNTING INSULATOR

15. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Remove the bolt and wire harness clamp bracket from the rear engine mounting insulator. |

|

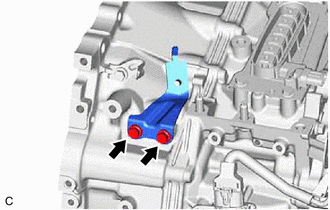

16. REMOVE REAR ENGINE MOUNTING BRACKET

|

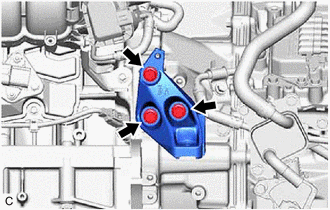

(a) Remove the 4 bolts and rear engine mounting bracket from the hybrid vehicle transaxle assembly. |

|

17. REMOVE HYBRID VEHICLE TRANSAXLE ASSEMBLY

|

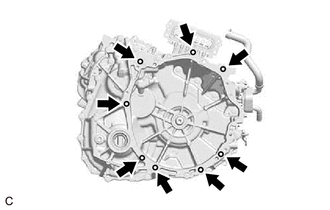

(a) Remove the 8 bolts and hybrid vehicle transaxle assembly from the engine assembly. NOTICE:

|

|

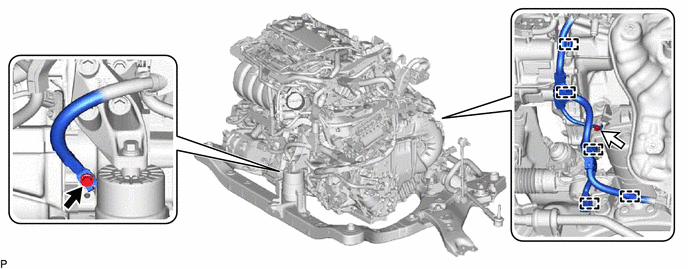

18. REMOVE MOTOR CABLE

19. REMOVE MOTOR COOLING COOLER

20. REMOVE NO. 1 TRANSMISSION CONTROL CABLE BRACKET

|

(a) Remove the 2 bolts and No. 1 transmission control cable bracket from the hybrid vehicle transaxle assembly. |

|

21. REMOVE HOSE BRACKET

|

(a) Remove the 2 bolts and hose bracket from the hybrid vehicle transaxle assembly. |

|

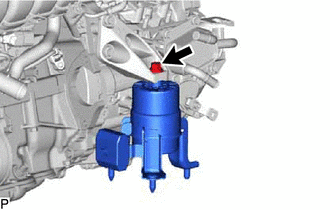

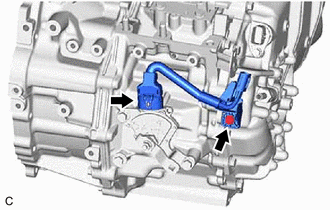

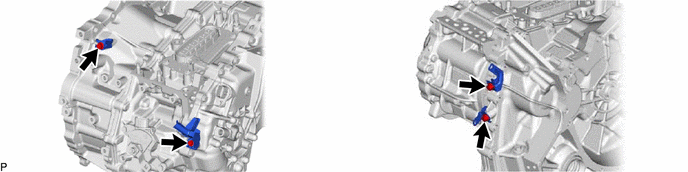

22. REMOVE TRANSMISSION WIRE

|

(a) Disconnect the connector. |

|

(b) Remove the bolt and transmission wire from the hybrid vehicle transaxle assembly.

23. REMOVE WIRE HARNESS CLAMP BRACKET

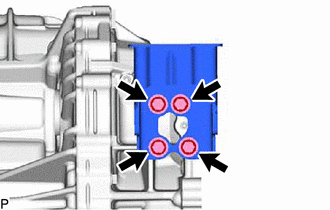

(a) Remove the 4 bolts and 4 wire harness clamp brackets from the hybrid vehicle transaxle assembly.

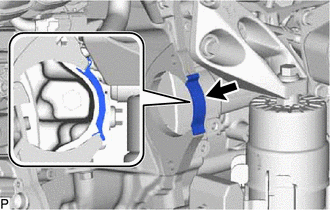

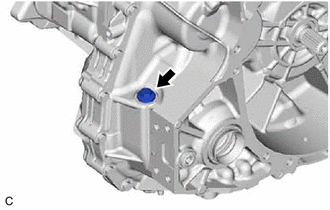

24. REMOVE TRANSAXLE HOUSING PLUG

|

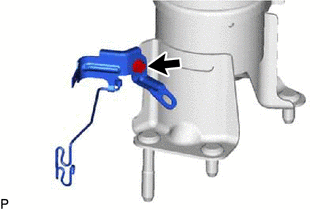

(a) Remove the transaxle housing plug and gasket from the hybrid vehicle transaxle assembly. |

|

25. REMOVE STUD BOLT

|

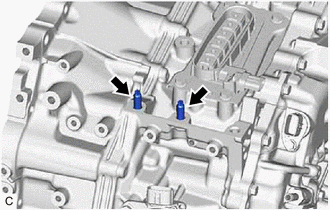

(a) Using an E8 "TORX" socket wrench, remove the 2 stud bolts from the hybrid vehicle transaxle assembly. |

|

26. REMOVE TRANSAXLE UNDER STOPPER BRACKET

|

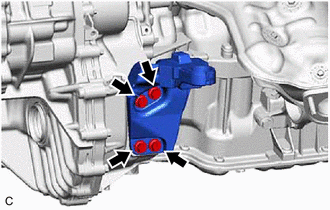

(a) Remove the 4 bolts and transaxle under stopper bracket from the hybrid vehicle transaxle assembly. |

|

27. REMOVE TRANSAXLE CASE PROTECTOR (for AWD)

|

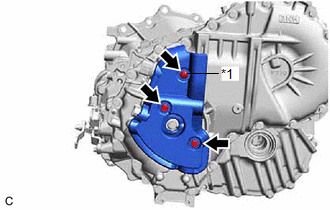

(a) Remove the 2 bolts. |

|

(b) Remove the clip and transaxle case protector from the hybrid vehicle transaxle assembly.

|

|

|

![2019 - 2022 MY RAV4 HV [02/2019 - 10/2022]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for HV Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)