| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001H3Y1 |

| Model Year Start: 2019 | Model: RAV4 HV | Prod Date Range: [02/2019 - 10/2019] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING UNIT (for A25A-FXS): REMOVAL; 2019 MY RAV4 HV [02/2019 - 10/2019] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed, installed or replaced during the air conditioning unit assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Auxiliary battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Parking support brake system (for HV model)* |

|||

|

Pre-collision system |

|||

|

Lighting system (EXT)(w/ AFS) |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system (for HV model) |

|||

|

Reset back door close position |

Power back door system (for HV model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

Steering sensor (Including removal and installation) |

Steering angle setting |

Parking assist monitor system |

|

|

Adjust steering angle |

Panoramic view monitor system (for HV model) |

||

|

Steering angle neutral point |

Parking assist monitor system |

||

|

Parking support brake system (for HV model) |

|||

|

Panoramic view monitor system (for HV model) |

|||

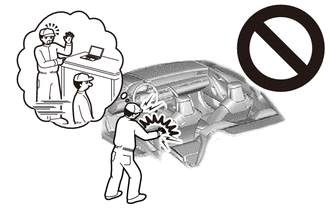

CAUTION:

- Wear protective gloves. Sharp areas on the parts may injure your hands.

- There is risk of injury.

CAUTION:

Some of these service operations affect the SRS airbag system. Read the precautionary notices concerning the SRS airbag system before servicing.

NOTICE:

-

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) auxiliary battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Auxiliary Battery Terminal

System Name

See Procedure

Vehicle enrolled in Toyota Entune system or safety connect system

6 minutes

Vehicle not enrolled in Toyota Entune system and safety connect system

1 minute

- After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

PROCEDURE

1. PRECAUTION

NOTICE:

Make sure to select face mode before disconnecting the cable from the negative (-) auxiliary battery terminal.

2. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

3. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

(a) for HFC-134a(R134a):

(b) for HFO-1234yf(R1234yf):

4. DRAIN ENGINE COOLANT (for Engine)

5. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

6. REMOVE COWL VENTILATOR SPLASH SHIELD (for TMC Made)

HINT:

Remove using the same procedure that is performed when replacement of the cowl ventilator splash shield is necessary.

7. REMOVE COWL VENTILATOR SPLASH SHIELD (for TMMC Made)

HINT:

Use the same procedure described as for the cowl ventilator splash shield (for TMC Made).

8. REMOVE COWL VENTILATOR PANEL SUB-ASSEMBLY

(a) w/ Windshield Deicer System:

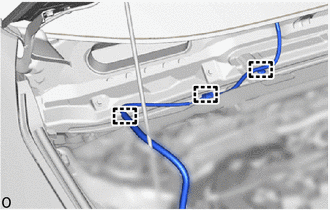

|

(1) Detach the clamp. |

|

(b) Detach the clamp.

|

Bolt |

|

Nut |

(c) Remove the 4 bolts, 4 nuts and cowl ventilator panel sub-assembly.

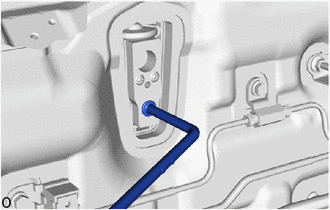

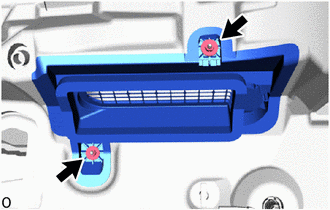

9. REMOVE HOLE PLUG

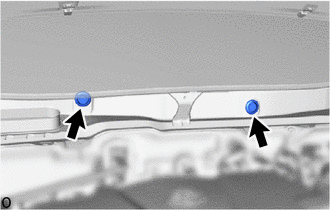

|

(a) Remove the 2 hole plugs. |

|

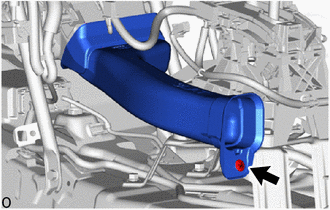

10. DISCONNECT SUCTION PIPE SUB-ASSEMBLY (for TMC Made)

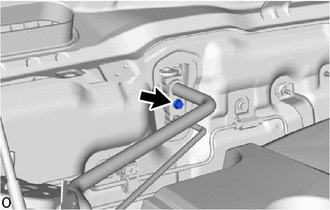

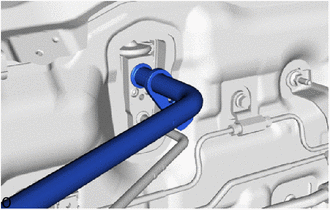

|

(a) Remove the bolt. |

|

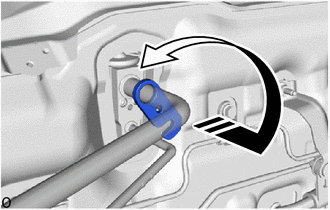

(b) Rotate the 1-point tightening plate as shown in the illustration.

|

Rotate in this Direction |

|

(c) Disconnect the suction pipe sub-assembly. NOTICE: Do not apply excessive force to the suction pipe sub-assembly. |

|

(d) Remove the O-ring from the suction pipe sub-assembly.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

11. DISCONNECT SUCTION TUBE SUB-ASSEMBLY B (for TMMC Made)

HINT:

Use the same procedure described as for the suction pipe sub-assembly (for TMC Made).

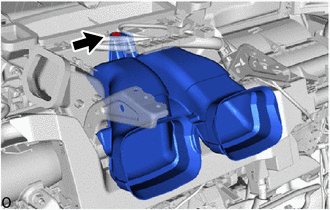

12. DISCONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

|

(a) Disconnect the air conditioning tube and accessory assembly. NOTICE: Do not apply excessive force to the air conditioning tube and accessory assembly. |

|

(b) Remove the O-ring from the air conditioning tube and accessory assembly.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

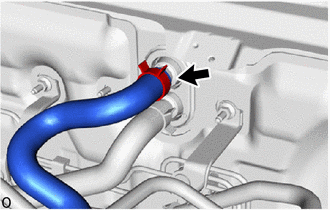

13. DISCONNECT OUTLET HEATER WATER HOSE

|

(a) Using pliers, grip the claws of the clip and slide the clip to disconnect the outlet heater water hose. NOTICE:

|

|

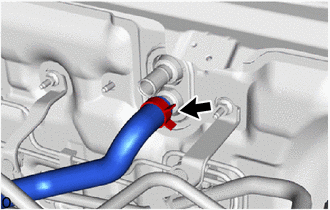

14. DISCONNECT INLET HEATER WATER HOSE

|

(a) Using pliers, grip the claws of the clip and slide the clip to disconnect the inlet heater water hose. NOTICE:

|

|

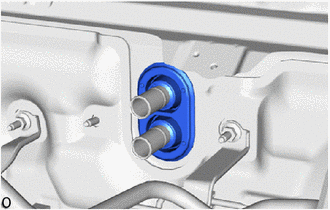

15. REMOVE HEATER GROMMET

|

(a) Remove the heater grommet. |

|

16. REMOVE FRONT SEAT ASSEMBLY LH

(a) for Manual Seat:

(b) for Power Seat:

17. REMOVE FRONT SEAT ASSEMBLY RH

HINT:

Use the same procedure described for the LH side.

18. REMOVE INSTRUMENT PANEL SAFETY PAD ASSEMBLY

19. REMOVE STEERING COLUMN ASSEMBLY

20. REMOVE NAVIGATION ECU WITH BRACKET (w/ Navigation System)

21. REMOVE DCM (TELEPHONE TRANSCEIVER ASSEMBLY) WITH BRACKET (w/ DCM)

(a) w/ Navigation System:

(b) w/o Navigation System:

22. REMOVE OUTER LAP BELT ANCHOR COVER

23. REMOVE REAR DOOR SCUFF PLATE LH

24. REMOVE FRONT SEAT OUTER BELT ASSEMBLY LH

25. REMOVE LOWER CENTER PILLAR GARNISH LH

(a) Remove the rear side of the front door opening trim weatherstrip LH so that the lower center pillar garnish LH can be removed.

(b) Remove the front side of the rear door opening trim weatherstrip LH so that the lower center pillar garnish LH can be removed.

(c) Remove the lower center pillar garnish LH.

26. REMOVE REAR DOOR SCUFF PLATE RH

HINT:

Use the same procedure described as for the rear door scuff plate LH.

27. REMOVE FRONT SEAT OUTER BELT ASSEMBLY RH

HINT:

Use the same procedure described as for the front seat outer belt assembly LH.

28. REMOVE LOWER CENTER PILLAR GARNISH RH

HINT:

Use the same procedure described as for the lower center pillar garnish LH.

29. REMOVE ACCELERATOR PEDAL PAD

30. REMOVE ACCELERATOR PEDAL ASSEMBLY

31. REMOVE FRONT FLOOR CAUTION PLATE COVER (w/ Cover)

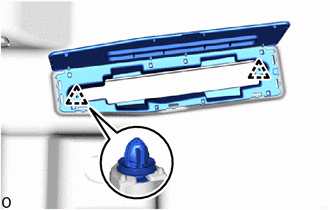

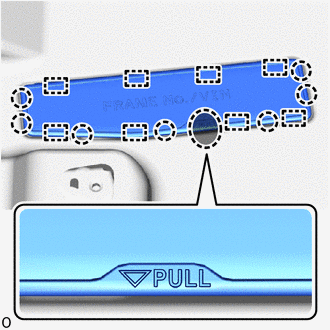

(a) Place your fingers at the positions shown in the illustration, detach the claw and guide and open the front floor caution plate cover.

|

Place Finger Here |

|

(b) Detach the clip and remove the front floor caution plate cover. |

|

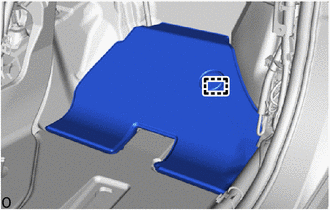

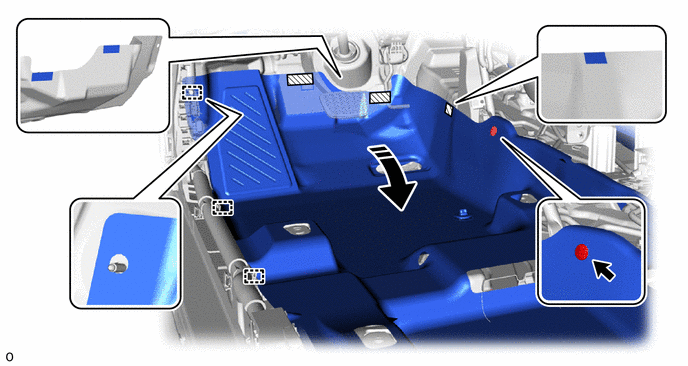

32. REMOVE FRONT FLOOR FRONT CARPET ASSEMBLY

(a) Remove the clip.

|

Fold Back |

|

Fastener |

(b) Detach the guide.

(c) Detach each fastener and fold back the front floor front carpet assembly as shown in the illustration.

(d) Remove the clip.

|

Fold Back |

- |

- |

(e) Detach the guide and fold back the front floor front carpet assembly as shown in the illustration.

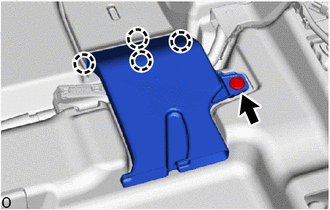

33. REMOVE NO. 3 DASH PANEL INSULATOR PAD

|

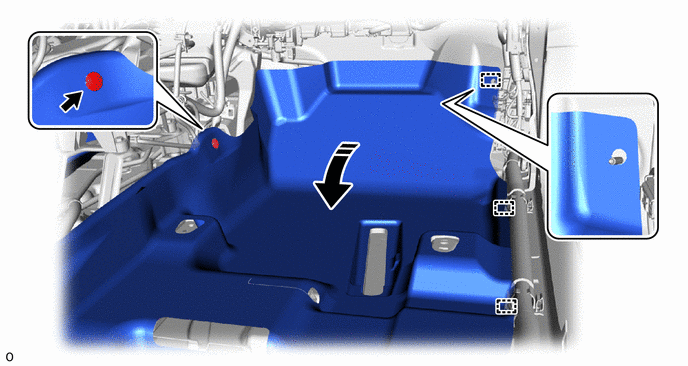

(a) Detach the guide and remove the No. 3 dash panel insulator pad. |

|

34. REMOVE REAR NO. 4 AIR DUCT (for TMC Made)

|

(a) Remove the clip. |

|

(b) Detach the claw and remove the rear No. 4 air duct.

35. REMOVE REAR NO. 4 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

36. REMOVE REAR NO. 3 AIR DUCT (for TMC Made)

|

(a) Detach the claw and remove the rear No. 3 air duct. |

|

37. REMOVE REAR NO. 2 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 3 air duct (for TMC Made).

38. REMOVE REAR NO. 2 AIR DUCT (for TMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

39. REMOVE REAR NO. 3 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

40. REMOVE REAR NO. 1 AIR DUCT

HINT:

Use the same procedure described as for the rear No. 3 air duct (for TMC Made).

41. REMOVE NO. 1 CONSOLE BOX DUCT

|

(a) Remove the clip and No. 1 console box duct. |

|

42. REMOVE NO. 2 HEATER TO REGISTER DUCT SUB-ASSEMBLY

|

(a) Remove the clip and No. 2 heater to register duct sub-assembly. |

|

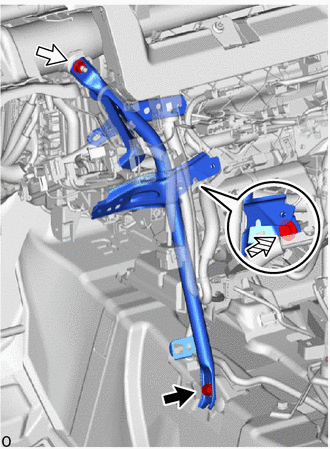

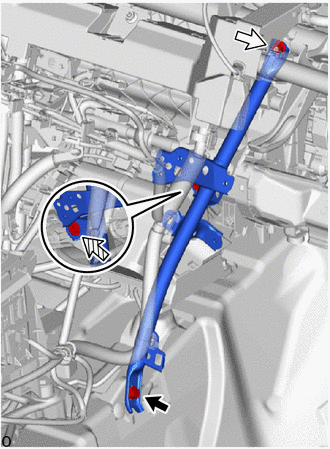

43. REMOVE NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY (for TMC Made)

44. REMOVE CENTER INSTRUMENT PANEL BRACKET SUB-ASSEMBLY (for TMMC Made)

HINT:

Use the same procedure described as for the No. 3 instrument panel to cowl brace sub-assembly (for TMC Made).

45. REMOVE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

46. DISCONNECT INSTRUMENT PANEL WIRE

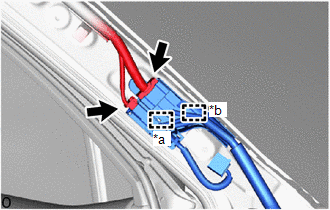

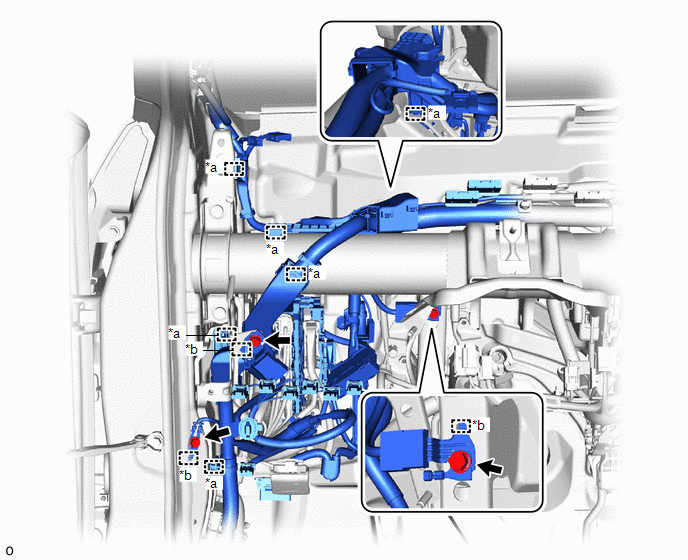

|

(a) Disconnect the 2 connectors. |

|

(b) Detach the clamp and guide.

(c) Remove the 3 bolts.

|

*a |

Clamp |

*b |

Guide |

(d) Detach the guide and disconnect the 3 ground wires.

(e) Detach the clamp.

(f) Remove the nut.

|

*A |

for Type A |

*B |

for Type B |

|

*a |

Clamp |

*b |

Guide |

|

Bolt |

|

Nut |

|

Connector |

|

Lever Connector |

(g) Remove the bolt.

(h) Detach the guide and disconnect the ground wire.

(i) Disconnect the connector.

(j) Detach the clamp.

(k) Disconnect the lever connector.

47. REMOVE ECU INTEGRATION BOX RH

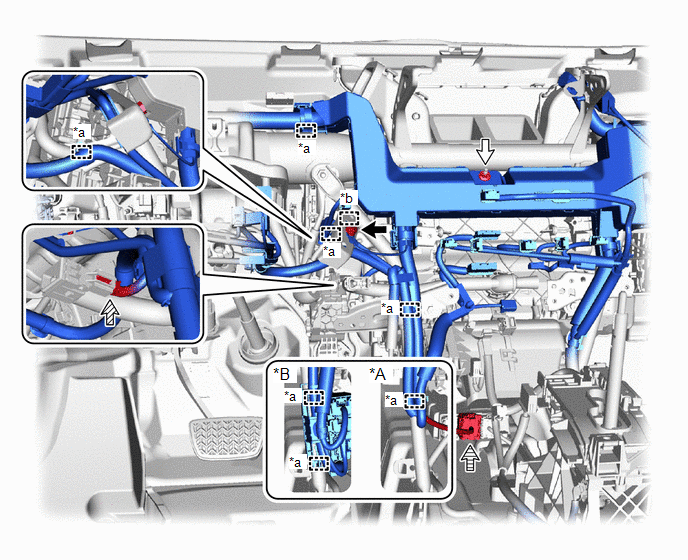

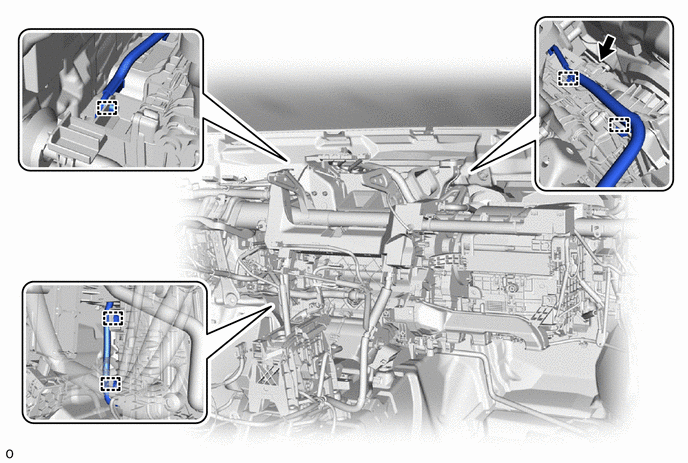

48. DISCONNECT INSTRUMENT PANEL WIRE

(a) Remove the 2 bolts.

|

*a |

Clamp |

*b |

Guide |

|

Bolt |

|

Connector |

(b) Detach the guide and disconnect the 2 ground wires.

(c) Disconnect the connector.

(d) Detach the clamp.

49. REMOVE NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) Remove the bolt, nut, screw and No. 1 instrument panel brace sub-assembly.

|

Bolt |

|

Nut |

|

Screw |

50. REMOVE NO. 2 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) Remove the bolt, nut, screw and No. 2 instrument panel brace sub-assembly.

|

Bolt |

|

Nut |

|

Screw |

51. DISCONNECT DRAIN COOLER HOSE

|

(a) Detach the clamp. |

|

(b) Disconnect the drain cooler hose from the cooler unit drain hose grommet.

NOTICE:

If the cooler unit drain hose grommet was removed from the body, replace it with a new one.

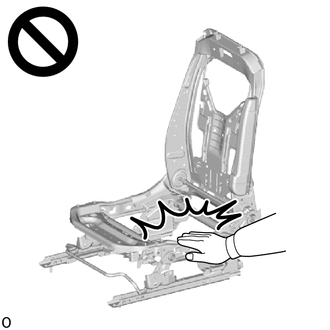

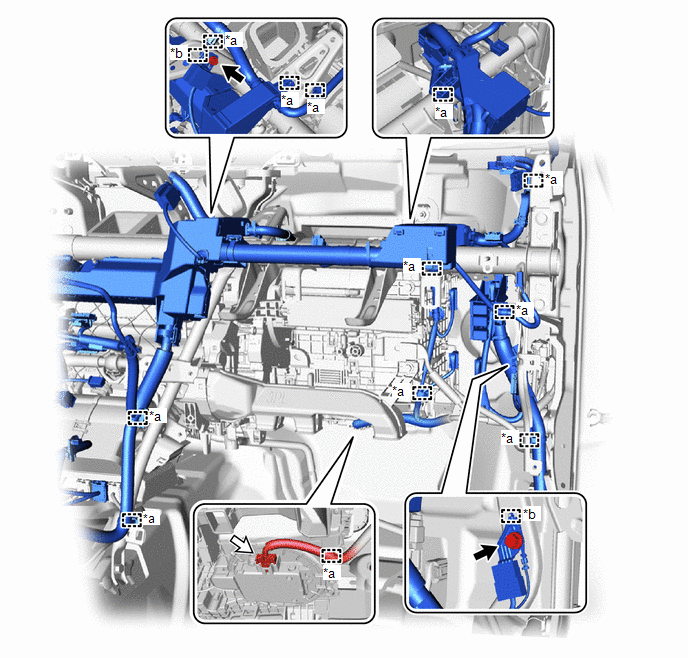

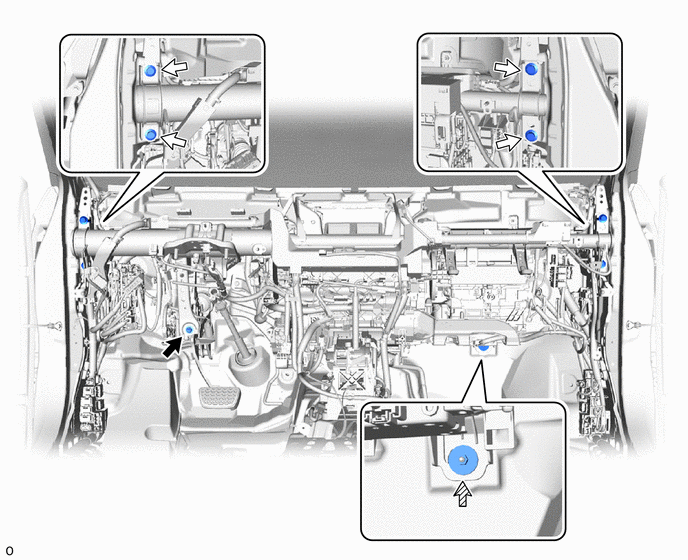

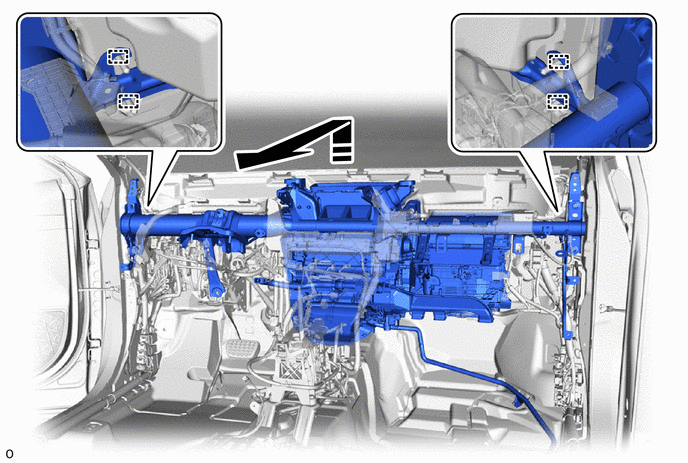

52. REMOVE INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONING UNIT ASSEMBLY

NOTICE:

- Be sure to support the air conditioning unit assembly when removing it because failure to do so may cause the bracket of the air conditioning unit assembly to break.

- When disassembling the air conditioning unit assembly, eliminate static electricity by touching the vehicle body to prevent the components from being damaged.

- Be careful not to damage the internal components of the instrument panel reinforcement assembly with air conditioning unit assembly on the glass etc. Only perform removal after first taking the appropriate actions.

- Do not allow the instrument panel reinforcement assembly with air conditioning unit assembly to strike the airbag sensor assembly. Doing so may damage the heater case, causing water leaks.

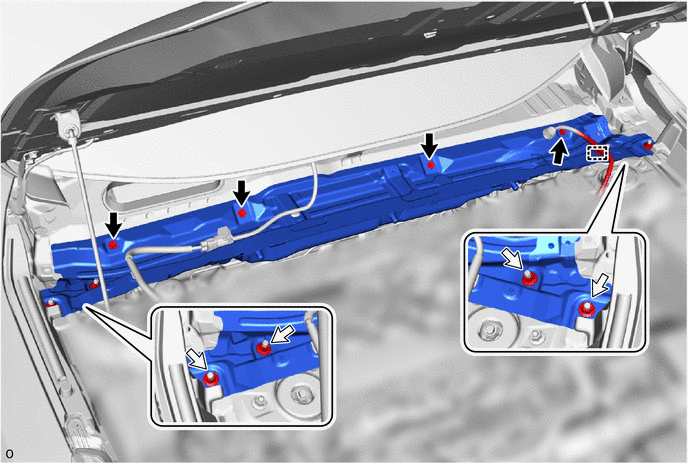

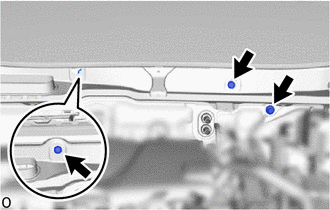

(a) Remove the 3 bolts (A).

|

Bolt (A) |

(b) Remove the bolt (B).

|

Bolt (B) |

|

Bolt (C) |

|

Nut |

- |

- |

(c) Remove the nut.

(d) Remove the 4 bolts (C).

(e) Remove the instrument panel reinforcement assembly with air conditioning unit assembly from the guide as shown in the illustration.

When carrying the instrument panel reinforcement assembly with air conditioning unit assembly, hold the bottom of the assembly. Do not hold the following parts.

- Do not hold the air conditioning harness assembly. Otherwise, static electricity from the technician may damage the air conditioning harness assembly.

- Do not hold the heater core or pipe of the heater radiator unit sub-assembly. Otherwise, the pipe may detach, the clamp may be damaged, or the crimped areas of the heater core and pipe of the heater radiator unit sub-assembly may be damaged, causing coolant to leak.

- Do not hold the air conditioning radiator damper servo sub-assembly, blower damper servo sub-assembly or link. Otherwise, the servo motor may become misaligned, causing abnormal operation noise, temperature control defects, or air leaks due to sealing defects in the doors.

- Do not hold the door. Doing so may cause air leaks due to closing defects resulting from excessive opening/closing. Also, keep the door free from oil and grease.

|

Remove in this Direction |

- |

- |

53. REMOVE AIR CONDITIONING AMPLIFIER ASSEMBLY

54. DISCONNECT INSTRUMENT PANEL WIRE

(a) Disconnect the connector.

(b) Detach the clamp.

55. REMOVE ID CODE BOX (IMMOBILIZER CODE ECU) (w/ ID Code Box)

56. REMOVE TRANSPONDER KEY ECU (IMMOBILIZER CODE ECU) (w/ Transponder ECU)

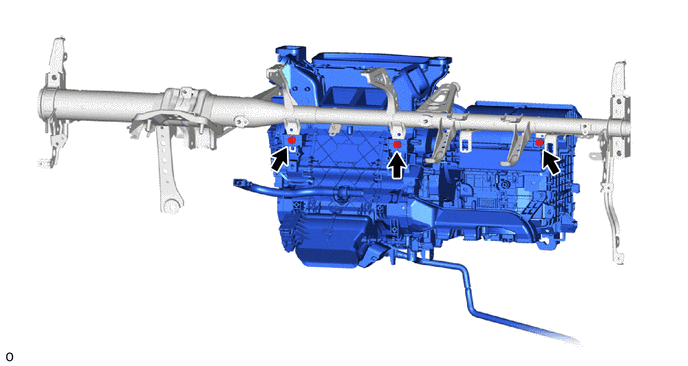

57. REMOVE AIR CONDITIONING UNIT ASSEMBLY

NOTICE:

- Be sure to support the air conditioning unit assembly when removing it because failure to do so may cause the bracket of the air conditioning unit assembly to break.

- When disassembling the air conditioning unit assembly, eliminate static electricity by touching the vehicle body to prevent the components from being damaged.

- Be careful not to damage the internal components of the instrument panel reinforcement assembly and air conditioning unit assembly on the glass etc. Only perform removal after first taking the appropriate actions.

- Store the air conditioning unit assembly in a location free from sand and other foreign matter.

(a) Remove the 3 bolts and air conditioning unit assembly from the instrument panel reinforcement assembly.

When carrying the air conditioning unit assembly, hold the bottom of the assembly. Do not hold the following parts.

- Do not hold the air conditioning harness assembly. Otherwise, static electricity from the technician may damage the air conditioning harness assembly.

- Do not hold the heater core or pipe of the heater radiator unit sub-assembly. Otherwise, the pipe may detach, the clamp may be damaged, or the crimped areas of the heater core and pipe of the heater radiator unit sub-assembly may be damaged, causing coolant to leak.

- Do not hold the air conditioning radiator damper servo sub-assembly, blower damper servo sub-assembly or link. Otherwise, the servo motor may become misaligned, causing abnormal operation noise, temperature control defects, or air leaks due to sealing defects in the doors.

- Do not hold the door. Doing so may cause air leaks due to closing defects resulting from excessive opening/closing. Also, keep the door free from oil and grease.

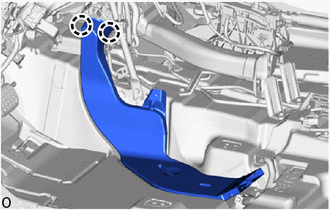

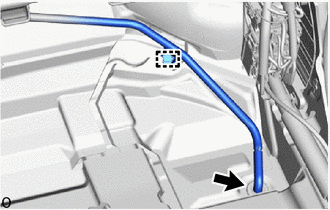

58. REMOVE NO. 1 AIR DUCT SUB-ASSEMBLY (for TMC Made)

HINT:

Perform this procedure only when replacement of the No. 1 air duct sub-assembly is necessary.

|

(a) Remove the 2 nuts and No. 1 air duct sub-assembly. |

|

59. REMOVE NO. 3 AIR DUCT SUB-ASSEMBLY (for TMMC Made)

HINT:

- Perform this procedure only when replacement of the No. 3 air duct sub-assembly is necessary.

- Use the same procedure described as for the No. 1 air duct sub-assembly (for TMC Made).

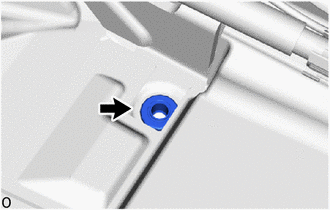

60. REMOVE COOLER UNIT DRAIN HOSE GROMMET

HINT:

Perform this procedure only when replacement of the cooler unit drain hose grommet is necessary.

|

(a) Remove the cooler unit drain hose grommet. NOTICE: After removing the cooler unit drain hose grommet, replace it with a new one to prevent water from entering. |

|

|

|

|

![2019 - 2022 MY RAV4 HV [02/2019 - 10/2022]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for HV Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)