| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001H9AY |

| Model Year Start: 2019 | Model: RAV4 HV | Prod Date Range: [02/2019 - 08/2020] |

| Title: A25A-FXS (ENGINE CONTROL): MASS AIR FLOW METER: ON-VEHICLE INSPECTION; 2019 - 2020 MY RAV4 HV [02/2019 - 08/2020] | ||

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT MASS AIR FLOW METER SUB-ASSEMBLY

HINT:

Perform "Inspection After Repair" after replacing the mass air flow meter sub-assembly.

(a) Read the value of Data List item "Mass Air Flow Sensor" using the Techstream.

NOTICE:

Perform the inspection of the mass air flow meter sub-assembly while it is installed to the air cleaner cap sub-assembly (installed to the vehicle).

(1) Check and ensure the following conditions:

- Turn off all electrical loads, such as the air conditioning, etc.

- Check that the coolant temperature is 75°C (167°F) or more.

- Put the shift lever in the N position.

(2) Connect the Techstream to the DLC3.

(3) Turn the power switch on (IG).

(4) Turn the Techstream on.

(5) Put the engine in Inspection Mode (Maintenance Mode).

Powertrain > Hybrid Control > Utility

|

Tester Display |

|---|

|

Inspection Mode |

(6) Start the engine.

(7) According to the display on the Techstream, read the Data List when the engine is running.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Mass Air Flow Sensor |

Standard Condition:

|

Techstream Display |

Condition |

Specified Condition |

|---|---|---|

|

Mass Air Flow Sensor |

Idling (shift lever in P, engine warmed up, inspection mode [maintenance mode] and not charge control) |

2.6 to 8.6 gm/sec |

|

2500 rpm (shift lever in P, engine warmed up and inspection mode [maintenance mode] ) |

6.2 to 18.6 gm/sec |

If the result is not as specified, clean the mass air flow meter sub-assembly.

After cleaning (air blowing) the mass air flow meter sub-assembly, perform an on-vehicle inspection of the mass air flow meter sub-assembly again and replace the mass air flow meter sub-assembly if the result is not as specified.

If the result is within the specified range, check the intake air temperature sensor (thermistor) resistance.

2. CLEAN MASS AIR FLOW METER SUB-ASSEMBLY

NOTICE:

If the mass air flow meter sub-assembly is removed and installed 10 times or more, the thread of the hole of the mass air flow meter sub-assembly may be damaged. Therefore, do not loosen the screws of the mass air flow meter sub-assembly.

(a) Remove the air cleaner cap sub-assembly.

(b) Clean the mass air flow meter sub-assembly.

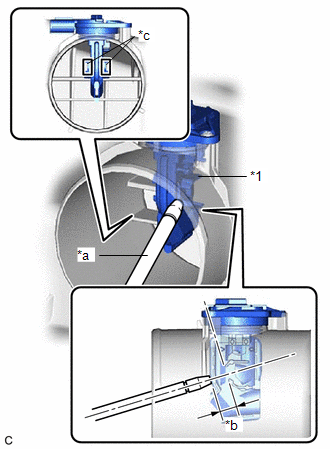

NOTICE:

- Do not contact the mass air flow meter sub-assembly with the nozzle of the air blow gun.

- Do not insert the nozzle of the air blow gun into the airflow hole.

|

*1 |

Mass Air Flow Meter Sub-assembly |

|

*a |

Air Blow Gun |

|

*b |

10 mm (0.394 in.) |

|

*c |

Airflow Hole |

|

(1) Using an air blow gun, clean the hole of the mass air flow meter sub-assembly by applying approximately 10 intermittent bursts of air to the airflow hole at a pressure of approximately 392 to 981 kPa (4.0 to 10.0 kgf/cm2, 57 to 142 psi). HINT: Apply 5 intermittent bursts of air to the airflow hole at 2 locations. |

|

(c) Install the air cleaner cap sub-assembly.

|

|

|

![2019 MY RAV4 RAV4 HV [02/2019 - 10/2019]; A25A-FXS (ENGINE CONTROL): SFI SYSTEM (w/ Canister Pump Module): INITIALIZATION](/t3Portal/stylegraphics/info.gif)