| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001HG8T |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [02/2019 - 12/2021] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (w/o Vacuum Brake Booster): C1252,C1253; Brake Booster Pump Motor on Time Abnormally Long; 2019 - 2021 MY RAV4 RAV4 HV [02/2019 - 12/2021] | ||

|

DTC |

C1252 |

Brake Booster Pump Motor on Time Abnormally Long |

|

DTC |

C1253 |

Pump Motor Relay |

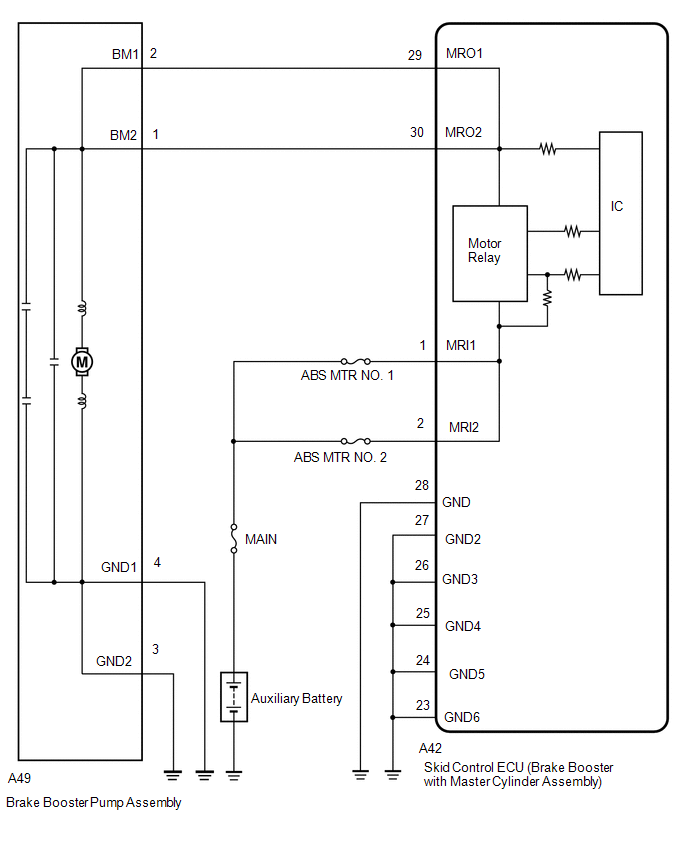

DESCRIPTION

The skid control ECU (brake booster with master cylinder assembly) detects decreases in the accumulator pressure according to the data from the accumulator pressure sensor, and then starts and stops the pump motor by operating the motor relay.

|

DTC No. |

Detection Item |

INF Code |

DTC Detection Condition |

Trouble Area |

Note |

|---|---|---|---|---|---|

|

C1252 |

Brake Booster Pump Motor on Time Abnormally Long |

311 |

The pump motor is operating continuously for 178 seconds or more. (When the relay is malfunctioning for 98 seconds or more.) |

|

- |

|

C1253 |

Pump Motor Relay |

321 322 323 324 325 326 327 328 329 |

|

|

- |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the skid control ECU (brake booster with master cylinder assembly) or brake actuator (brake booster with master cylinder assembly), perform initialization and calibration of the linear solenoid valve.

- Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (ABS MOTOR RELAY) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Select the Active Test on the Techstream.

Chassis > ABS/VSC/TRAC > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

ECB Motor Relay |

ABS motor relay |

Relay ON/OFF |

ECB: Electronically Controlled Brake System |

Chassis > ABS/VSC/TRAC > Active Test

|

Tester Display |

|---|

|

ECB Motor Relay |

(d) Select the Data List on the Techstream.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ECB Motor Relay |

ABS motor relay |

ON or OFF |

ON: Relay on OFF: Relay off |

ECB: Electronically Controlled Brake System |

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

ECB Motor Relay |

(e) Check the operating condition of the ABS motor relay when operating it with the Techstream.

|

Result |

Proceed to |

|---|---|

|

ABS motor relay in the Data List turns ON/OFF using the Active Test. |

A |

|

ABS motor relay in the Data List does not change using the Active Test. |

B |

| B |

|

|

|

2. |

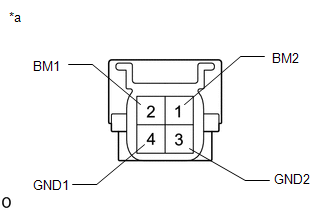

INSPECT BRAKE BOOSTER PUMP ASSEMBLY |

|

(a) Turn the ignition switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

(c) Disconnect the A49 brake booster pump assembly connectors.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2 (BM1) - 4 (GND1) |

Always |

Below 10 Ω |

|

1 (BM2) - 3 (GND2) |

Always |

Below 10 Ω |

|

2 (BM1) - 1 (BM2) |

Always |

Below 1 Ω |

|

4 (GND1) - 3 (GND2) |

Always |

Below 1 Ω |

| NG |

|

|

|

3. |

CHECK HARNESS AND CONNECTOR (GND TERMINAL) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (GND CIRCUIT) |

|

|

4. |

READ VALUE USING TECHSTREAM (ACCUMULATOR PRESSURE SENSOR) |

(a) Reconnect the A49 brake booster pump assembly connectors.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Select the Data List on the Techstream.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Accumulator Sensor |

Accumulator pressure sensor |

Min.: 0.00 V, Max.: 5.00 V |

Specified value: 2.90 to 4.20 V |

When brake fluid is stored in the accumulator: Accumulator pressure changes in accordance with volume of fluid stored in the accumulator |

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

Accumulator Sensor |

(e) Depress the brake pedal 4 or 5 times to operate the pump motor.

(f) Wait for 30 seconds without depressing the brake pedal.

(g) Check that the accumulator pressure sensor output value change is within the specified range.

OK:

Accumulator pressure sensor output value change is less than 0.55 V.

| NG |

|

|

|

5. |

RECONFIRM DTC |

(a) Clear the DTCs.

Chassis > ABS/VSC/TRAC > Clear DTCs

(b) Turn the ignition switch off.

(c) Turn the ignition switch to ON.

(d) Check if the same DTC is output.

Chassis > ABS/VSC/TRAC > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs C1252 and C1253 are not output. |

A |

|

DTCs C1252 and/or C1253 are output. |

B |

| A |

|

| B |

|

|

6. |

PERFORM ACTIVE TEST USING TECHSTREAM (SOLENOID VALVE) |

(a) Select the Active Test on the Techstream.

Chassis > ABS/VSC/TRAC > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

ECB Solenoid (SMC/SRC/SCC) |

Switching solenoid valve (SMC/SRC/SCC) |

Solenoid ON/OFF |

|

Chassis > ABS/VSC/TRAC > Active Test

|

Tester Display |

|---|

|

ECB Solenoid (SMC/SRC/SCC) |

HINT:

The Active Test can be performed when the following conditions are met.

- ABS main relay is on.

- Shift lever is in P.

- Parking brake is applied.

- Vehicle speed is 0 km/h (0 mph).

(b) Perform the Active Test of the solenoid using the Techstream.

(c) Select the Data List on the Techstream.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Wheel Cylinder Pressure Sensor |

Wheel cylinder pressure sensor |

Min.: 0.00 V, Max.: 5.00 V |

Brake pedal released: 0.10 to 0.90 V |

Reading increases when brake pedal is depressed |

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

Wheel Cylinder Pressure Sensor |

(d) Check that the output value of the wheel cylinder pressure sensor does not increase.

OK:

The output value of the wheel cylinder pressure sensor does not increase.

HINT:

If the output value increases, there may be brake fluid leaks in the brake actuator.

| OK |

|

| NG |

|

|

7. |

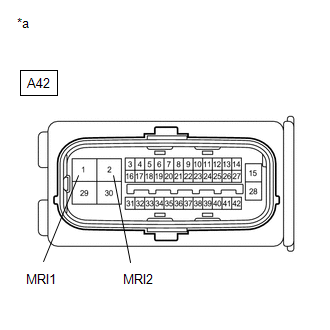

CHECK HARNESS AND CONNECTOR (MRI TERMINAL) |

|

(a) Turn the ignition switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

(c) Disconnect the A42 skid control ECU (brake booster with master cylinder assembly) connector.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-1 (MRI1) - Body ground |

Always |

11 to 14 V |

|

A42-2 (MRI2) - Body ground |

Always |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (MRI CIRCUIT) |

|

|

8. |

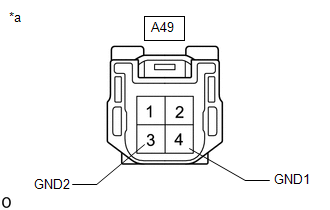

CHECK HARNESS AND CONNECTOR (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY - BRAKE BOOSTER PUMP ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

(b) Disconnect the A49 brake booster pump assembly connectors.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-29 (MRO1) - A49-2 (BM1) |

Always |

Below 1 Ω |

|

A42-29 (MRO1) or A49-2 (BM1) - Body ground |

Always |

10 kΩ or higher |

|

A42-30 (MRO2) - A49-1 (BM2) |

Always |

Below 1 Ω |

|

A42-30 (MRO2) or A49-1 (BM2) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2019 - 2021 MY RAV4 RAV4 HV [02/2019 - 12/2021]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (w/o Vacuum Brake Booster): UTILITY](/t3Portal/stylegraphics/info.gif)