|

Last Modified: 01-30-2024 |

6.11:8.1.0 |

Doc ID: RM100000001LRDA |

|

Model Year Start: 2020 |

Model: RAV4 |

Prod Date Range: [10/2019 - 06/2020] |

|

Title: A25A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL; 2020 MY RAV4 [10/2019 - 06/2020] |

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during engine unit removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure

|

Necessary Procedure

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Link

|

|

Battery terminal is disconnected/reconnected

|

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes)

|

Stop and start system

|

![2019 - 2021 MY RAV4 [11/2018 - 12/2021]; STOP AND START: STOP AND START SYSTEM: PRECAUTION](/t3Portal/stylegraphics/info.gif)

|

|

Perform steering sensor zero point calibration

|

Lane control system

|

![2019 - 2021 MY RAV4 RAV4 HV [11/2018 - 12/2021]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Parking support brake system (for Gasoline model)*

|

|

Pre-collision system

|

|

Memorize steering angle neutral point

|

Parking assist monitor system

|

![2019 - 2022 MY RAV4 RAV4 HV [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PARKING ASSIST MONITOR SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Panoramic view monitor system (for Gasoline model)

|

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PANORAMIC VIEW MONITOR SYSTEM (for Gasoline Model): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Reset back door close position

|

Power back door system (for Gasoline model)

|

![2019 - 2023 MY RAV4 [11/2018 - 10/2023]; DOOR / HATCH: POWER BACK DOOR SYSTEM (for Gasoline Model): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Back door lock initialization

|

Power door lock control system

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; DOOR LOCK: POWER DOOR LOCK CONTROL SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM

|

w/ Canister Pump Module:

-

Perform Vehicle Identification Number (VIN) registration

|

DTC P063051 is output

|

![2020 MY RAV4 [10/2019 - 08/2020]; A25A-FKS (ENGINE CONTROL): SFI SYSTEM (w/ Canister Pump Module): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

w/o Canister Pump Module:

-

Perform Vehicle Identification Number (VIN) or frame number registration

|

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (ENGINE CONTROL): SFI SYSTEM (w/o Canister Pump Module): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Code registration

|

Engine start function

|

w/ Smart Key System:

![2020 MY RAV4 [10/2019 - 08/2020]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): REGISTRATION](/t3Portal/stylegraphics/info.gif)

w/o Smart Key System:

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; THEFT DETERRENT / KEYLESS ENTRY: IMMOBILISER SYSTEM (for Gasoline Model without Smart Key System): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for UB80E:

-

If transaxle compensation code read from ECM

-

Perform reset memory

-

Transfer transaxle compensation code

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

for Initialization:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for Registration:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for UB80F:

-

If transaxle compensation code read from ECM

-

Perform reset memory

-

Transfer transaxle compensation code

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

for Initialization:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for Registration:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

-

Replacement of engine assembly

-

Gas leak from exhaust system is repaired

-

Replacement of throttle body with motor assembly

-

Replacement of cam timing control motor with EDU assembly

-

Removal and installation of a cam timing control motor with EDU assembly

-

Replacement of camshaft timing gear assembly

-

Removal and installation of a camshaft timing gear assembly

-

Replacement of cylinder head sub-assembly

-

Replacement of camshaft (for intake or exhaust camshaft)

-

Replacement of camshaft timing exhaust gear assembly

-

Replacement of port fuel injector assembly

-

Replacement of direct fuel injector assembly

-

Replacement of fuel pump assembly (for high pressure side)

-

Replacement of engine coolant temperature sensor

-

Replacement of spark plug

-

Replacement of ignition coil assembly

-

Replacement of EGR valve assembly

-

Replacement of knock control sensor

-

Replacement of air fuel ratio sensor (sensor 2)

|

Inspection after repair

|

-

Poor idle, etc.

-

Engine start function, etc.

|

w/ Canister Pump Module:

![2020 MY RAV4 [10/2019 - 08/2020]; A25A-FKS (ENGINE CONTROL): SFI SYSTEM (w/ Canister Pump Module): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

w/o Canister Pump Module:

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (ENGINE CONTROL): SFI SYSTEM (w/o Canister Pump Module): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of automatic transaxle assembly

|

for UB80E:

-

Reset memory

-

Input transaxle compensation code into ECM

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

for Initialization:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for Registration:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for UB80F:

-

Reset memory

-

Input transaxle compensation code into ECM

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

for Initialization:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for Registration:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Automatic transaxle fluid

|

ATF thermal degradation estimate reset

|

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly

|

for UB60E:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for UB60F:

![2019 - 2024 MY RAV4 [11/2018 - ]; UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Suspension, tires, etc.

(The vehicle height changes because of suspension or tire replacement)

|

Television camera assembly optical axis (Back camera position setting)

|

Parking assist monitor system

|

![2019 - 2022 MY RAV4 RAV4 HV [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PARKING ASSIST MONITOR SYSTEM: CALIBRATION](/t3Portal/stylegraphics/info.gif)

|

-

Parking assist ECU initialization

-

Adjust steering angle

|

Panoramic view monitor system (for Gasoline model)

|

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PANORAMIC VIEW MONITOR SYSTEM (for Gasoline Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)

|

|

Front wheel alignment adjustment

|

-

Perform reset memory

-

Perform acceleration sensor zero point calibration and store system information memorization.

|

-

VSC is disabled or malfunctions

-

DTCs are output

-

Slip indicator light illuminates

-

ABS warning light illuminates

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (w/ Vacuum Brake Booster): UTILITY](/t3Portal/stylegraphics/info.gif)

|

|

Front bumper assembly (Including removal and installation)

|

Front television camera view adjustment

|

Panoramic view monitor system (for Gasoline model)

|

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PANORAMIC VIEW MONITOR SYSTEM (for Gasoline Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)

|

NOTICE:

-

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Auxiliary Battery Terminal

|

System Name

|

See Procedure

|

|

Vehicle enrolled in Toyota Audio Multimedia system or safety connect system

|

6 minutes

|

|

Vehicle not enrolled in Toyota Audio Multimedia system and safety connect system

|

1 minute

|

-

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)

PROCEDURE

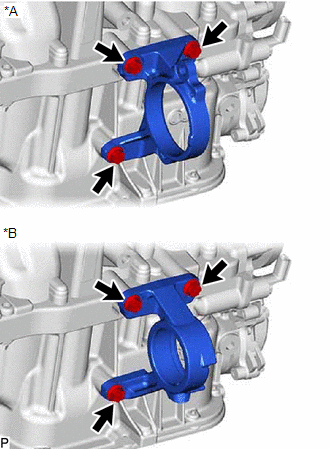

1. REMOVE DRIVE SHAFT BEARING BRACKET

|

(a) Remove the 3 bolts and drive shaft bearing bracket.

|

|

|

*A

|

for 2WD

|

|

*B

|

for 4WD/AWD

|

|

|

2. REMOVE V-RIBBED BELT

Click here

![2019 - 2024 MY RAV4 [11/2018 - ]; MAINTENANCE: A25A-FKS DRIVE BELT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

3. REMOVE GENERATOR ASSEMBLY

-

for 100 A, 130 A Type:

Click here

![2020 MY RAV4 [10/2019 - 08/2020]; A25A-FKS (BATTERY / CHARGING): GENERATOR (for 100 A, 130 A Type): REMOVAL+](/t3Portal/stylegraphics/info.gif)

-

for 150 A Type:

Click here

![2020 MY RAV4 [10/2019 - 08/2020]; A25A-FKS (BATTERY / CHARGING): GENERATOR (for 150 A Type): REMOVAL+](/t3Portal/stylegraphics/info.gif)

-

for VALEO Made:

Click here

![2020 MY RAV4 [10/2019 - 08/2020]; A25A-FKS (BATTERY / CHARGING): GENERATOR (for VALEO Made): REMOVAL+](/t3Portal/stylegraphics/info.gif)

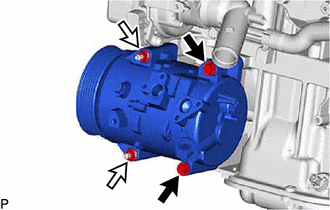

4. REMOVE COMPRESSOR ASSEMBLY WITH PULLEY

(a) for Type A:

(1) Remove the 2 bolts and 2 nuts.

|

Bolt

|

|

Nut

|

|

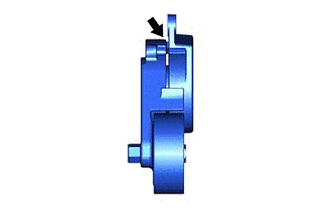

(2) Using an E8 "TORX" socket wrench, remove the 2 stud bolts and compressor assembly with pulley.

|

|

(b) for Type B:

|

(1) Remove the 4 bolts and compressor assembly with pulley.

|

|

5. REMOVE NO. 2 ENGINE COVER

|

(a) Remove the 2 bolts and No. 2 engine cover from the No. 2 timing chain cover assembly.

|

|

6. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

NOTICE:

-

Do not apply or add any oil or grease to the belt tensioner to prevent abnormal noises from the belt tensioner pulley, belt squealing, etc.

-

Do not allow oil or grease to adhere to the moving parts of the belt tensioner, as this may cause malfunctions.

|

(a) Remove the 2 bolts and V-ribbed belt tensioner assembly from the No. 2 timing chain cover assembly.

|

|

7. REMOVE NO. 2 TIMING CHAIN COVER INSULATOR

|

(a) Remove the No. 2 timing chain cover insulator from the V-ribbed belt tensioner assembly.

|

|

8. REMOVE TIMING GEAR COVER INSULATOR

|

(a) Using an 8 mm socket wrench, remove the bolt, plate washer and timing gear cover insulator from the No. 2 timing chain cover assembly.

|

|

9. REMOVE NO. 3 TIMING CHAIN COVER

|

(a) Using an 8 mm socket wrench, remove the bolt, plate washer and No. 3 timing chain cover from the No. 2 timing chain cover assembly.

|

|

10. REMOVE NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY

|

(a) Slide the clip and disconnect the No. 2 water by-pass pipe sub-assembly from the outlet water by-pass sub-assembly.

|

|

(b) Remove the bolt and No. 2 water by-pass pipe sub-assembly.

11. REMOVE FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY)

|

(a) Remove the bolt to disconnect the flow shutting valve (water by-pass hose assembly).

|

|

|

(b) Remove the 2 bolts and the water hose clamp bracket.

|

|

|

(c) Slide the clip and disconnect the flow shutting valve (water by-pass hose assembly) from the water by-pass outlet sub-assembly.

HINT:

Use a container to catch any engine coolant which flows out of the flow shutting valve (water by-pass hose assembly) and water by-pass outlet sub-assembly.

|

|

12. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

|

(a) Remove the 5 bolts and No. 1 exhaust manifold heat insulator from the exhaust manifold.

|

|

13. REMOVE MANIFOLD STAY

Click here

![2019 - 2020 MY RAV4 [02/2019 - 08/2020]; A25A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD: REMOVAL+](/t3Portal/stylegraphics/info.gif)

14. REMOVE EXHAUST MANIFOLD

|

(a) Using a 12 mm deep socket wrench, remove the 7 nuts and separate the exhaust manifold from the cylinder head sub-assembly.

|

|

|

(b) Remove the exhaust manifold to head gasket from the cylinder head sub-assembly.

|

|

15. REMOVE THROTTLE BODY WITH MOTOR ASSEMBLY

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (ENGINE CONTROL): THROTTLE BODY: REMOVAL+](/t3Portal/stylegraphics/info.gif)

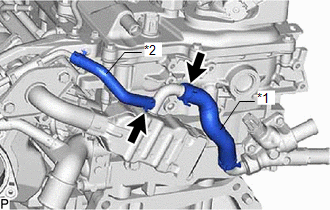

16. REMOVE EGR COOLER ASSEMBLY

|

(a) Slide the clip and disconnect the water hose from the EGR cooler assembly.

|

|

|

*1

|

No. 3 Water By-pass Hose

|

|

*2

|

Water Hose

|

|

|

(b) Slide the clip and disconnect the No. 3 water by-pass hose from the EGR cooler assembly.

|

(c) Remove the 5 bolts, EGR cooler assembly, EGR cooler gasket and EGR valve gasket.

|

|

17. REMOVE NO. 1 EGR COOLER BRACKET

|

(a) Remove the 2 bolts and No. 1 EGR cooler bracket from the EGR valve bracket and water outlet.

|

|

18. REMOVE NO. 1 EGR PIPE SUB-ASSEMBLY

|

(a) Using an 8 mm socket wrench, remove the 4 bolts, No. 1 EGR pipe sub-assembly, EGR inlet gasket and EGR valve adapter gasket.

|

|

19. REMOVE NO. 4 WATER BY-PASS HOSE

|

(a) Slide the clip and remove the No. 4 water by-pass hose from the EGR valve assembly.

|

|

20. REMOVE EGR VALVE ASSEMBLY

|

(a) Disconnect the clamp.

|

|

(b) Slide the clip and disconnect the No. 8 water by-pass hose from the EGR valve assembly.

|

(c) Using an 8 mm socket wrench, remove the bolt and disconnect the fuel pipe sub-assembly from the EGR valve bracket.

|

|

(d) Using an 8 mm socket wrench, remove the bolt.

|

(e) Remove the EGR valve assembly vertically.

|

|

|

(f) Using an 8 mm socket wrench, remove the bolt and EGR valve bracket.

|

|

21. REMOVE NO. 3 WATER BY-PASS PIPE

|

(a) Using an 8 mm socket wrench, remove the bolt and No. 3 water by-pass pipe from the intake manifold.

|

|

(b) Slide the clip and disconnect the No. 3 water by-pass pipe from the water outlet.

22. REMOVE NO. 2 WATER BY-PASS PIPE

(b) Using an 8 mm socket wrench, remove the 2 bolts (B) and No. 2 water by-pass pipe.

23. REMOVE INTAKE MANIFOLD

Click here

![2019 - 2020 MY RAV4 [02/2019 - 08/2020]; A25A-FKS (INTAKE / EXHAUST): INTAKE MANIFOLD: REMOVAL+](/t3Portal/stylegraphics/info.gif)

24. REMOVE NO. 1 INTAKE MANIFOLD TO HEAD GASKET

Click here

![2019 - 2020 MY RAV4 [02/2019 - 08/2020]; A25A-FKS (INTAKE / EXHAUST): INTAKE MANIFOLD: REMOVAL+](/t3Portal/stylegraphics/info.gif)

25. DISCONNECT FUEL TUBE SUB-ASSEMBLY

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (FUEL): FUEL PUMP (for High Pressure): REMOVAL+](/t3Portal/stylegraphics/info.gif)

26. REMOVE NO. 1 FUEL PIPE SUB-ASSEMBLY

|

(a) Using a 17 mm union nut wrench, loosen the 2 union nuts of the No. 1 fuel pipe sub-assembly.

|

|

27. REMOVE FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (FUEL): FUEL PUMP (for High Pressure): REMOVAL+](/t3Portal/stylegraphics/info.gif)

28. REMOVE NO. 7 WATER BY-PASS HOSE

|

(a) Slide the 2 clips and remove the No. 7 water by-pass hose.

|

|

29. REMOVE SENSOR WIRE

|

(a) Disconnect the 4 connectors.

|

|

(b) Detach the 3 clamps.

(c) Using an 8 mm socket wrench, remove the bolt and sensor wire from the water inlet with thermostat sub-assembly.

30. REMOVE NO. 6 ENGINE WIRE

|

(a) Disconnect the 4 connectors.

|

|

(b) Detach the 2 clamps.

(c) Remove the 2 nuts and No. 6 engine wire from the wire harness clamp bracket.

31. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Using an 8 mm socket wrench, remove the 2 bolts and wire harness clamp bracket from the No. 1 ventilation case.

|

|

32. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

Click here

![2019 - 2020 MY RAV4 [11/2018 - 06/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

33. REMOVE NO. 1 DELIVERY PIPE SPACER

Click here

![2019 - 2020 MY RAV4 [11/2018 - 06/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

34. REMOVE INJECTOR VIBRATION INSULATOR

Click here

![2019 - 2020 MY RAV4 [11/2018 - 06/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

35. REMOVE NO. 5 ENGINE WIRE

Click here

![2019 - 2020 MY RAV4 [11/2018 - 06/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

36. REMOVE PORT FUEL INJECTOR ASSEMBLY

Click here

![2019 - 2020 MY RAV4 [11/2018 - 06/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

37. REMOVE FUEL DELIVERY PIPE

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Direct Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

38. REMOVE DIRECT FUEL INJECTOR ASSEMBLY

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Direct Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

39. REMOVE FUEL INJECTOR SEAL

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (FUEL): FUEL INJECTOR (for Direct Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

40. REMOVE IGNITION COIL ASSEMBLY

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (ENGINE CONTROL): IGNITION COIL AND SPARK PLUG: REMOVAL+](/t3Portal/stylegraphics/info.gif)

41. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

(a) Remove the engine oil level dipstick.

|

(b) Using an 8 mm socket wrench, remove the bolt and engine oil level dipstick guide from the cylinder head sub-assembly.

|

|

|

(c) Remove the O-ring from the engine oil level dipstick guide.

|

|

42. REMOVE NO. 3 EXHAUST MANIFOLD HEAT INSULATOR

|

(a) Remove the 2 bolts and No. 3 exhaust manifold heat insulator from the cylinder block sub-assembly.

|

|

43. REMOVE PURGE VALVE (PURGE VSV)

-

w/ Canister Pump Module:

Click here

![2019 - 2024 MY RAV4 [11/2018 - ]; A25A-FKS (EMISSION CONTROL): PURGE VALVE(w/ Canister Pump Module): REMOVAL+](/t3Portal/stylegraphics/info.gif)

-

w/o Canister Pump Module:

Click here

![2019 - 2020 MY RAV4 [11/2018 - 08/2020]; A25A-FKS (EMISSION CONTROL): PURGE VALVE (w/o Canister Pump Module): REMOVAL+](/t3Portal/stylegraphics/info.gif)

44. REMOVE NO. 2 VACUUM SWITCHING VALVE BRACKET

|

(a) Using an 8 mm socket wrench, remove the 2 bolts and No. 2 vacuum switching valve bracket from the cylinder head sub-assembly.

|

|

|