- DTC judgment completed

- System normal

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001QOI5 |

| Model Year Start: 2021 | Model: RAV4 | Prod Date Range: [08/2020 - ] |

| Title: A25A-FKS (ENGINE CONTROL): SFI SYSTEM: P001700; Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor B; 2021 - 2024 MY RAV4 RAV4 HV [08/2020 - ] | ||

|

DTC |

P001700 |

Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor B |

DESCRIPTION

Refer to DTC P001313.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P001700 |

Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor B |

Deviation in the crankshaft position sensor signal and camshaft position sensor (for exhaust camshaft) signal (2 trip detection logic). |

|

Comes on |

DTC stored |

|

MONITOR DESCRIPTION

To monitor the correlation of the exhaust camshaft position and crankshaft position, the ECM checks the VVT learned value while the engine is idling. The VVT learned value is calibrated based on the camshaft position and crankshaft position. The exhaust valve timing is set to the most advanced angle while the engine is idling. If the VVT learned value is out of the specified range in consecutive driving cycles, the ECM illuminates the MIL and stores this DTC.

MONITOR STRATEGY

|

Related DTCs |

P0017: Camshaft timing misalignment at idling (for exhaust camshaft) |

|

Required Sensors/Components (Main) |

Camshaft timing exhaust gear assembly |

|

Required Sensors/Components (Related) |

Camshaft position sensor Crankshaft position sensor |

|

Frequency of Operation |

Continuous |

|

Duration |

Within 1 minute |

|

MIL Operation |

2 driving cycles |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

None |

|

Engine speed |

500 to 1000 rpm |

TYPICAL MALFUNCTION THRESHOLDS

|

Either of the following conditions is met |

A or B |

|

A. VVT learned value at maximum advanced valve timing |

Less than 80°CA (Crankshaft Angle) |

|

B. VVT learned value at maximum advanced valve timing |

More than 102.5°CA (Crankshaft Angle) |

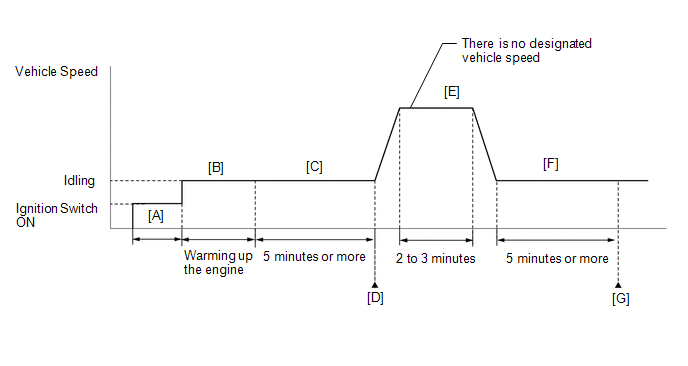

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON.

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON [A].

- Turn the Techstream on.

- Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher [B].

- Idle the engine for 5 minutes or more [C].

- Enter the following menus: Powertrain / Engine / Trouble Codes [D].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P001700.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

- If the judgment result is INCOMPLETE, perform steps [E] through [G].

-

[A] to [D]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

-

Drive the vehicle for 2 to 3 minutes [E].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Idle the engine for 5 minutes or more [F].

- Enter the following menus: Powertrain / Engine / Trouble Codes [G].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

-

Check the DTC judgment result.

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

-

[A] to [G]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

CAUTION / NOTICE / HINT

HINT:

- The monitor for this DTC detects when the timing chain is shifted by one tooth or more (except Mexico Models).

- The monitor for this DTC detects when the timing chain is shifted by 2 to 3 teeth or more (for Mexico Models).

- Read Freeze Frame Data using the Techstream. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P001700) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC P001700 is output |

A |

|

DTC P001700 and other DTCs are output |

B |

HINT:

If any DTCs other than P001700 are output, troubleshoot those DTCs first.

| B |

|

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE EXHAUST VVT OCV DUTY RATIO BANK 1) |

HINT:

If the VVT system can be operated through the Active Test, it can be assumed that the VVT system is operating normally.

(a) Connect the Techstream to the DLC3.

(b) Start the engine.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Active Test / Control the Exhaust VVT OCV Duty Ratio Bank 1 / Data List / Exhaust VVT Change Angle Bank 1.

Powertrain > Engine > Active Test

|

Active Test Display |

|---|

|

Control the Exhaust VVT OCV Duty Ratio Bank 1 |

|

Data List Display |

|---|

|

Exhaust VVT Change Angle Bank 1 |

(e) Perform the Active Test. Check that the displacement angle varies.

OK:

Displacement angle varies.

| NG |

|

|

|

3. |

CHECK ENGINE MECHANICAL SYSTEM |

(a) Check for mechanical malfunctions that affect the valve timing, such as a jumped tooth or stretching of the timing chain.

HINT:

Perform "Inspection After Repair" after repairing or replacing the engine mechanical system.

| OK |

|

| NG |

|

REPAIR OR REPLACE MALFUNCTIONING PARTS, COMPONENT AND AREA |

|

4. |

INSPECT CAM TIMING OIL CONTROL SOLENOID ASSEMBLY |

(a) Inspect the cam timing oil control solenoid assembly.

| NG |

|

|

|

5. |

INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY) |

(a) Inspect the camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly).

| NG |

|

REPLACE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY) |

|

|

6. |

INSPECT CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

(a) Inspect the camshaft timing exhaust gear assembly.

HINT:

Perform "Inspection After Repair" after replacing the camshaft timing exhaust gear assembly.

| NG |

|

|

|

7. |

CLEAR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(e) Turn the ignition switch off and wait for at least 30 seconds.

|

|

8. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P001700) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus: Powertrain / Engine / Trouble Codes / Pending.

(c) Read the pending DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

DTC P001700 is output |

B |

| A |

|

| B |

|

|

|

|

![2021 - 2024 MY RAV4 RAV4 HV [08/2020 - ]; A25A-FKS (ENGINE CONTROL): SFI SYSTEM: P001313; Camshaft Position "B" - Actuator Bank 1 Circuit Open+](/t3Portal/stylegraphics/info.gif)