-

If transaxle compensation code read from ECM

- Perform reset memory

- Transfer transaxle compensation code

- Perform road test to allow ECM to learn

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001ZV6L |

| Model Year Start: 2022 | Model: RAV4 | Prod Date Range: [12/2021 - 10/2022] |

| Title: UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): OIL COOLER: REMOVAL; 2022 MY RAV4 [12/2021 - 10/2022] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during transmission oil cooler removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Battery terminal is disconnected/reconnected |

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes) |

Stop and start system |

|

|

Perform steering sensor zero point calibration |

Lane control system |

||

|

Parking support brake system (for Gasoline model)* |

|||

|

Pre-collision system |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system (for Gasoline model) |

|||

|

Reset back door close position |

Power back door system (for Gasoline model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

ECM |

Perform Vehicle Identification Number (VIN) or frame number registration |

DTC P063051 is output |

|

|

Code registration |

Engine start function |

||

|

|

|

||

|

|||

NOTICE:

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Battery Terminal

|

System Name |

See Procedure |

|---|---|

|

Vehicle enrolled in Toyota Audio Multimedia system or safety connect system |

6 minutes |

|

Vehicle not enrolled in Toyota Audio Multimedia system and safety connect system |

1 minute |

PROCEDURE

1. REMOVE BATTERY

2. REMOVE ECM

3. REMOVE BATTERY CLAMP SUB-ASSEMBLY

4. REMOVE FRONT FENDER FRONT SPLASH SHIELD LH

5. REMOVE FRONT FENDER FRONT SPLASH SHIELD RH

6. REMOVE NO. 1 ENGINE UNDER COVER

7. REMOVE NO. 2 ENGINE UNDER COVER ASSEMBLY

8. REMOVE FRONT FENDER APRON SEAL LH

9. DRAIN ENGINE COOLANT

10. DRAIN AUTOMATIC TRANSAXLE FLUID

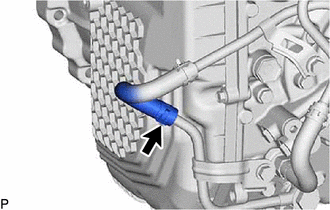

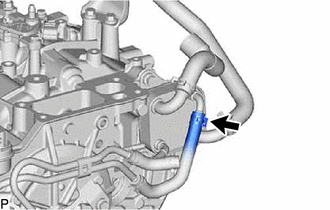

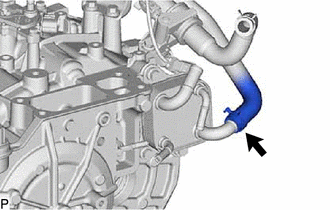

11. DISCONNECT OUTLET NO. 1 OIL COOLER HOSE

|

(a) Slide the clip and disconnect the outlet No. 1 oil cooler hose from the oil cooler union sub-assembly. HINT: Use a container to catch any automatic transaxle fluid which flows out of the outlet No. 1 oil cooler hose and oil cooler union sub-assembly. |

|

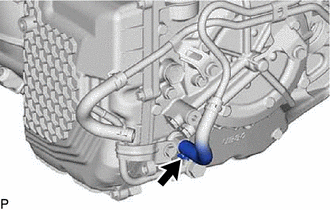

12. DISCONNECT INLET NO. 1 OIL COOLER HOSE

|

(a) Slide the clip and disconnect the inlet No. 1 oil cooler hose from the No. 1 oil cooler outlet tube sub-assembly. HINT: Use a container to catch any automatic transaxle fluid which flows out of the inlet No. 1 oil cooler hose and No. 1 oil cooler outlet tube sub-assembly. |

|

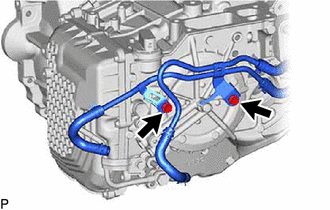

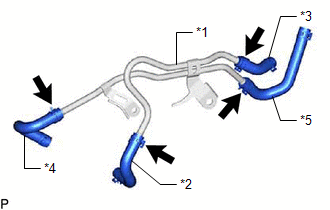

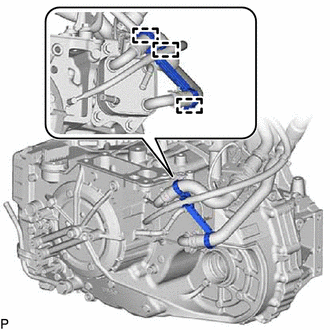

13. REMOVE NO. 1 OIL COOLER TUBE SUB-ASSEMBLY WITHOUT HOSE

|

(a) Remove the 2 bolts to disconnect the No. 1 oil cooler tube sub-assembly without hose from the automatic transaxle case sub-assembly. |

|

|

(b) Slide the clip and disconnect the inlet No. 2 oil cooler hose from the transmission oil cooler. HINT: Use a container to catch any automatic transaxle fluid which flows out of the inlet No. 2 oil cooler hose and transmission oil cooler. |

|

|

(c) Slide the clip and disconnect the outlet No. 2 oil cooler hose to remove the No. 1 oil cooler tube sub-assembly without hose from the transmission oil cooler. HINT: Use a container to catch any automatic transaxle fluid which flows out of the outlet No. 2 oil cooler hose and transmission oil cooler. |

|

|

(d) Slide the 4 clips and remove the inlet No. 1 oil cooler hose, inlet No. 2 oil cooler hose, outlet No. 1 oil cooler hose and outlet No. 2 oil cooler hose from the No. 1 oil cooler tube sub-assembly without hose. |

|

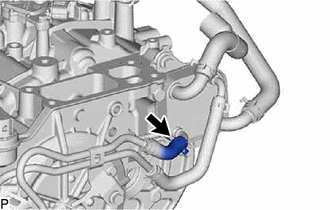

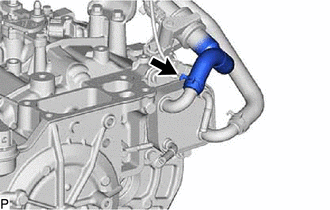

14. DISCONNECT NO. 1 WATER BY-PASS HOSE

|

(a) Disengage the 3 clamps to remove the transmission breather clamp. |

|

|

(b) Slide the clip and disconnect the No. 1 water by-pass hose from the transmission oil cooler. HINT: Use a container to catch any coolant which flows out of the No. 1 water by-pass hose and transmission oil cooler. |

|

15. DISCONNECT WATER BY-PASS HOSE ASSEMBLY

|

(a) Slide the clip and disconnect the water by-pass hose assembly from the transmission oil cooler. HINT: Use a container to catch any coolant which flows out of the water by-pass hose assembly and transmission oil cooler. |

|

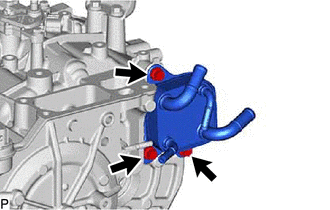

16. REMOVE TRANSMISSION OIL COOLER

|

(a) Remove the 3 bolts and the transmission oil cooler from the automatic transaxle case sub-assembly. |

|

|

|

|

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for Gasoline Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)