| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM10000000258BR |

| Model Year Start: 2023 | Model: RAV4 HV | Prod Date Range: [10/2022 - ] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING UNIT (for A25A-FXS): INSTALLATION; 2023 - 2024 MY RAV4 HV [10/2022 - ] | ||

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

A bolt without a torque specification is shown in the standard bolt chart.

PROCEDURE

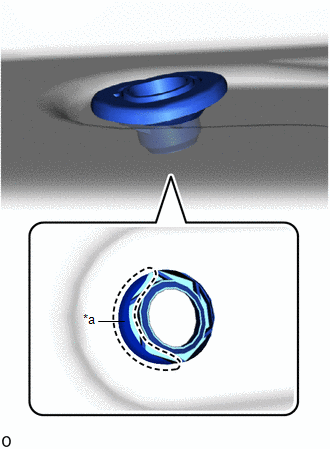

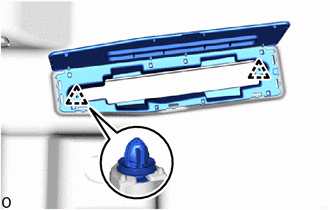

1. INSTALL COOLER UNIT DRAIN HOSE GROMMET

Perform this procedure only when removal/installation of the cooler unit drain hose grommet is necessary.

NOTICE:

After removing the cooler unit drain hose grommet, replace it with a new one to prevent water from entering.

|

(a) Attach one side of the lip on a new cooler unit drain hose grommet (approximately 1/3 of the circumference) to the body hole (fit it to the hole). |

|

(b) Press the entire upper surface of the rib on the cooler unit drain hose grommet, and fit the entire circumference of the lip to the hole.

NOTICE:

- If the lip on the cooler unit drain hose grommet is not completely fit to the hole, water or noise may enter the interior. When fitting the lip to the hole, make sure that there are no gaps between the lip and body.

- Do not allow any foreign matter to be trapped between the cooler unit drain hose grommet and installation area, as this may allow noise to enter.

- Removing the cooler unit drain hose grommet after it has been installed damages the lip due to burrs on the body punch hole (vehicle exterior). This may reduce contact between the edge of the lip and body and cause water to enter the interior. Therefore, do not reuse the cooler unit drain hose grommet.

- When installing the cooler unit drain hose grommet, do not leave the lip only partially fit to the hole (as in the previous step). This may reduce contact due to lip deformation and cause water to enter the interior. Once you have started to install the part, complete the installation without stopping.

|

Rib Upper Surface |

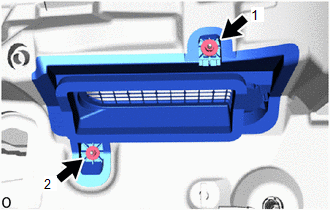

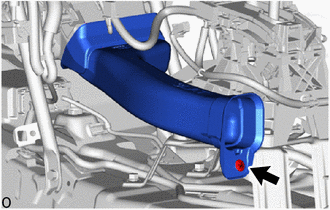

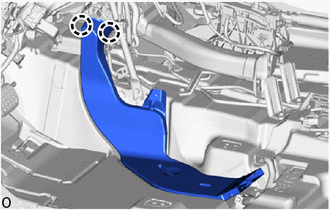

2. INSTALL NO. 1 AIR DUCT SUB-ASSEMBLY (for TMC Made)

HINT:

Perform this procedure only when removal/installation of the No. 1 air duct sub-assembly is necessary.

|

(a) Install the No. 1 air duct sub-assembly with the 2 nuts in the order shown in the illustration. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} NOTICE:

|

|

3. INSTALL NO. 3 AIR DUCT SUB-ASSEMBLY (for TMMC Made)

HINT:

- Perform this procedure only when removal/installation of the No. 3 air duct sub-assembly is necessary.

- Use the same procedure described as for the No. 1 air duct sub-assembly (for TMC Made).

4. INSTALL AIR CONDITIONING UNIT ASSEMBLY

NOTICE:

- Be sure to support the air conditioning unit assembly when installing it because failure to do so may cause the bracket of the air conditioning unit assembly to break.

- When installing the air conditioning unit assembly, eliminate static electricity by touching the vehicle body to prevent the components from being damaged.

- Be careful not to damage the internal components of the instrument panel reinforcement assembly and air conditioning unit assembly on the glass etc. Only perform installation after first taking the appropriate actions.

- Do not allow the air conditioning unit assembly to strike the airbag sensor assembly. Doing so may damage the heater case, causing water leaks.

(a) Temporarily set the air conditioning unit assembly nearby the position where it is to be installed.

When carrying the air conditioning unit assembly, hold the bottom of the assembly. Do not hold the following parts.

- Do not hold the air conditioning harness assembly. Otherwise, static electricity from the technician may damage the air conditioning harness assembly.

- Do not hold the heater core or pipe of the heater radiator unit sub-assembly. Otherwise, the pipe may detach, the clamp may be damaged, or the crimped areas of the heater core and pipe of the heater radiator unit sub-assembly may be damaged, causing coolant to leak.

- Do not hold the air conditioning radiator damper servo sub-assembly, blower damper servo sub-assembly or link. Otherwise, the servo motor may become misaligned, causing abnormal operation noise, temperature control defects, or air leaks due to sealing defects in the doors.

- Do not hold the door. Doing so may cause air leaks due to closing defects resulting from excessive opening/closing. Also, keep the door free from oil and grease.

(b) Temporarily install the air conditioning unit assembly to the instrument panel reinforcement assembly with the 3 bolts.

5. INSTALL ID CODE BOX (IMMOBILIZER CODE ECU) (w/ ID Code Box)

6. INSTALL TRANSPONDER KEY ECU (IMMOBILIZER CODE ECU) (w/ Transponder ECU)

7. CONNECT INSTRUMENT PANEL WIRE

(a) Attach the clamp.

(b) Connect the connector.

8. INSTALL AIR CONDITIONING AMPLIFIER ASSEMBLY

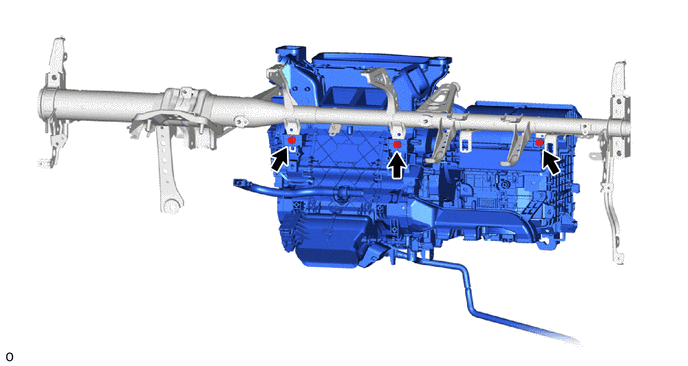

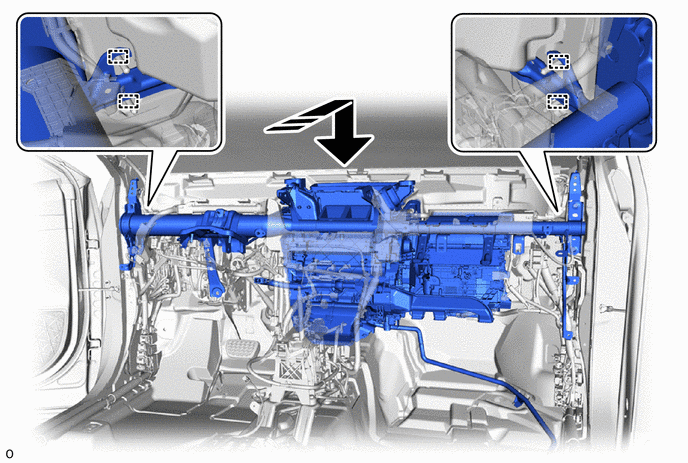

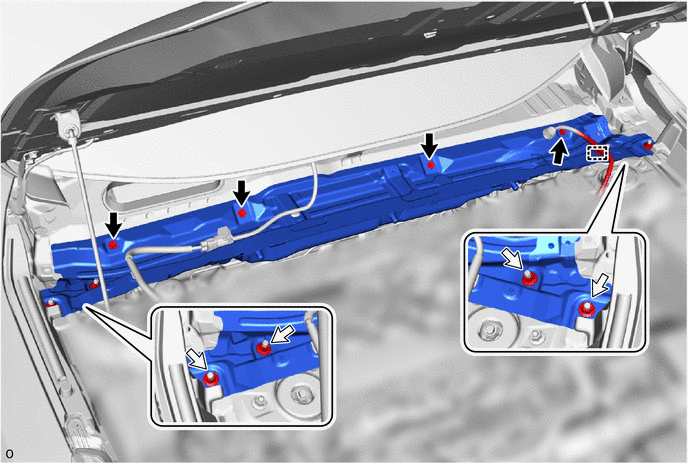

9. INSTALL INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONING UNIT ASSEMBLY

NOTICE:

- Be sure to support the air conditioning unit assembly when installing it because failure to do so may cause the bracket of the air conditioning unit assembly to break.

- When installing the air conditioning unit assembly, eliminate static electricity by touching the vehicle body to prevent the components from being damaged.

- Be careful not to damage the internal components of the instrument panel reinforcement assembly with air conditioning unit assembly on the glass etc. Only perform installation after first taking the appropriate actions.

(a) Install the instrument panel reinforcement assembly with air conditioning unit assembly to the guide as shown in the illustration.

When carrying the instrument panel reinforcement assembly with air conditioning unit assembly, hold the bottom of the assembly. Do not hold the following parts.

- Do not hold the air conditioning harness assembly. Otherwise, static electricity from the technician may damage the air conditioning harness assembly.

- Do not hold the heater core or pipe of the heater radiator unit sub-assembly. Otherwise, the pipe may detach, the clamp may be damaged, or the crimped areas of the heater core and pipe of the heater radiator unit sub-assembly may be damaged, causing coolant to leak.

- Do not hold the air conditioning radiator damper servo sub-assembly, blower damper servo sub-assembly or link. Otherwise, the servo motor may become misaligned, causing abnormal operation noise, temperature control defects, or air leaks due to sealing defects in the doors.

- Do not hold the door. Doing so may cause air leaks due to closing defects resulting from excessive opening/closing. Also, keep the door free from oil and grease.

NOTICE:

- Do not allow the heater radiator unit sub-assembly heater pipe or cooler expansion valve to strike the body.

- Make sure that both parts are securely installed to the guide.

|

Install in this Direction |

- |

- |

(b) Temporarily install the 4 bolts (C).

|

Bolt (B) |

|

Bolt (C) |

|

Nut |

- |

- |

(c) Temporarily install the bolt (B).

(d) Temporarily install the 3 bolts (A).

|

Bolt (A) |

(e) Temporarily install the nut.

(f) Tighten the 4 bolts (C).

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

(g) Tighten the 3 bolts (A).

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

(h) Tighten the bolt (B).

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

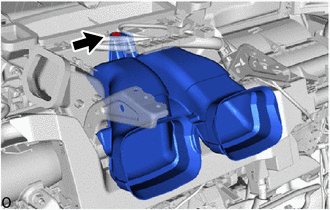

10. INSTALL HEATER GROMMET

|

(a) Install the heater grommet. NOTICE:

|

|

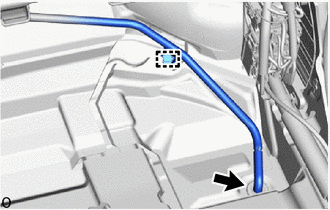

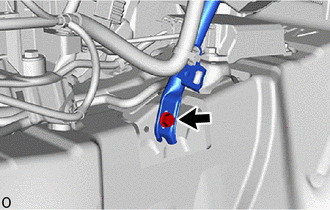

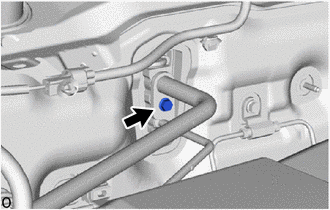

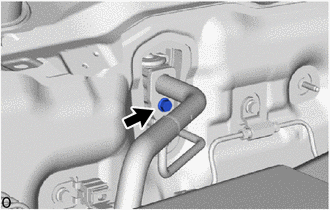

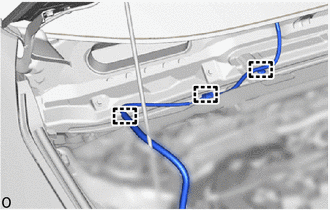

11. CONNECT DRAIN COOLER HOSE

NOTICE:

If the cooler unit drain hose grommet was removed from the body, replace it with a new one.

|

(a) Connect the drain cooler hose to the cooler unit drain hose grommet. NOTICE: When installing the drain cooler hose, make sure it is not twisted or crushed. Otherwise, water may leak into the interior. |

|

(b) Attach the clamp.

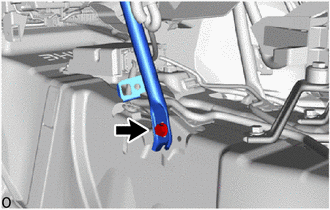

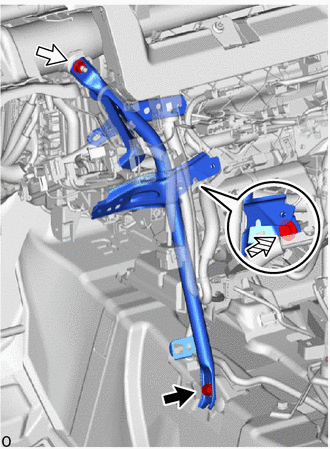

12. TEMPORARILY INSTALL NO. 2 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) Temporarily install the No. 2 instrument panel brace sub-assembly with the bolt, nut and screw.

|

Bolt |

|

Nut |

|

Screw |

13. TEMPORARILY INSTALL NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) Temporarily install the No. 1 instrument panel brace sub-assembly with the bolt, nut and screw.

|

Bolt |

|

Nut |

|

Screw |

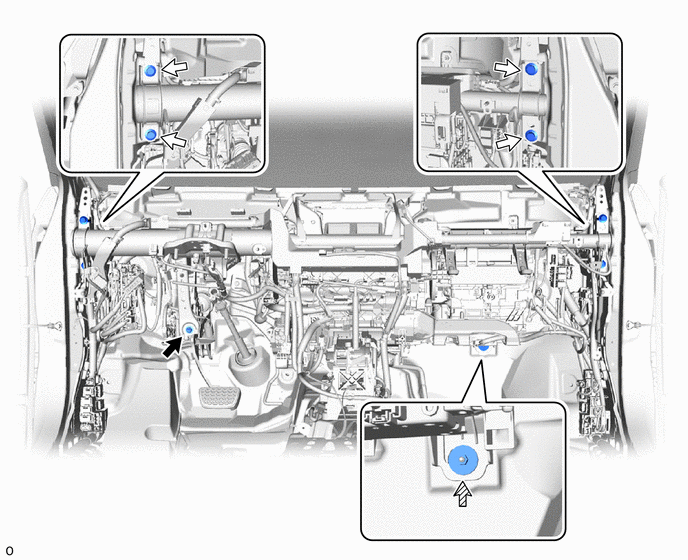

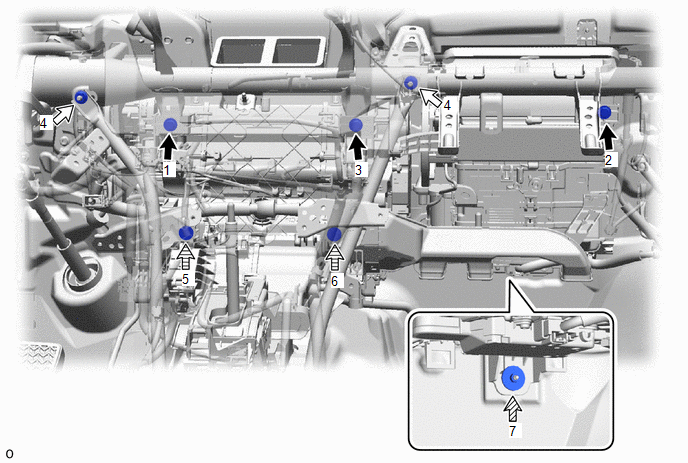

14. TIGHTEN INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONING UNIT ASSEMBLY

(a) Tighten the 3 bolts, 2 nuts (A), and 2 screws in the order shown in the illustration.

HINT:

5 and 6 can be done in either order.

Torque:

Bolt :

9.8 N·m {100 kgf·cm, 87 in·lbf}

Nut (A) :

18 N·m {184 kgf·cm, 13 ft·lbf}

|

Bolt |

|

Nut (A) |

|

Nut (B) |

|

Screw |

(b) Tighten the nut (B).

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

|

(c) Tighten the No. 2 instrument panel brace sub-assembly with the bolt. Torque: 20 N·m {204 kgf·cm, 15 ft·lbf} |

|

|

(d) Tighten the No. 1 instrument panel brace sub-assembly with the bolt. Torque: 20 N·m {204 kgf·cm, 15 ft·lbf} |

|

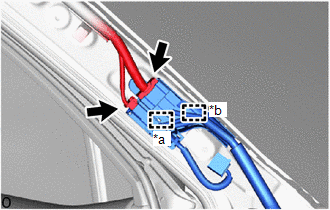

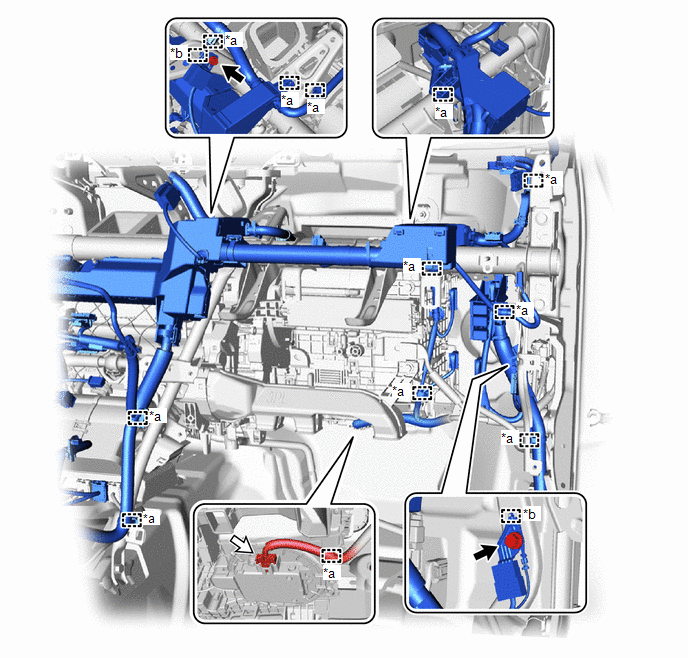

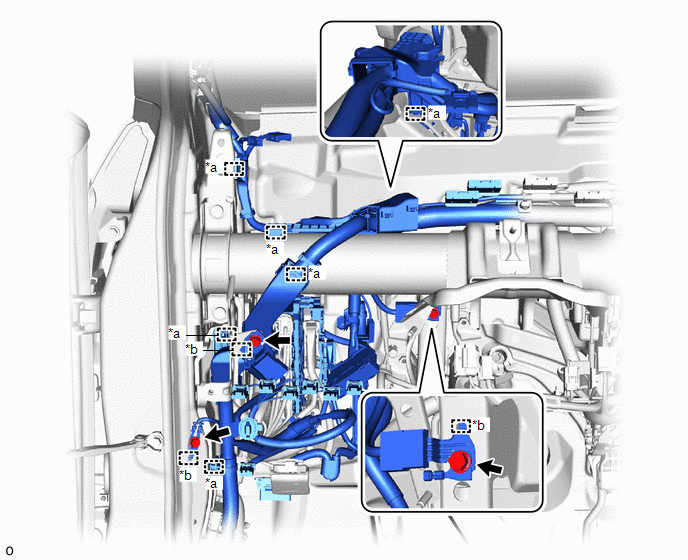

15. CONNECT INSTRUMENT PANEL WIRE

(a) Attach the clamp.

|

*a |

Clamp |

*b |

Guide |

|

Bolt |

|

Connector |

(b) Connect the connector.

(c) Attach the guide.

(d) Connect the 2 ground wires with the 2 bolts.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

16. INSTALL ECU INTEGRATION BOX RH

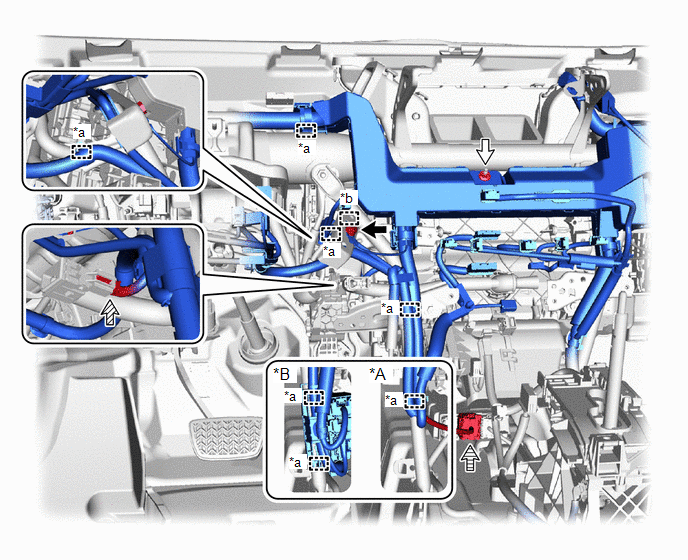

17. CONNECT INSTRUMENT PANEL WIRE

(a) Connect the lever connector.

|

*A |

for Type A |

*B |

for Type B |

|

*a |

Clamp |

*b |

Guide |

|

Bolt |

|

Nut |

|

Connector |

|

Lever Connector |

(b) Attach the clamp.

(c) Connect the connector.

(d) Attach the guide.

(e) Connect the ground wire with the bolt.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

(f) Install the nut.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(g) Attach the clamp.

|

*a |

Clamp |

*b |

Guide |

(h) Attach the guide.

(i) Connect the 3 ground wires with the 3 bolts.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

|

(j) Connect the 2 connectors. |

|

(k) Attach the guide and clamp.

18. INSTALL INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

19. INSTALL NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY (for TMC Made)

20. INSTALL CENTER INSTRUMENT PANEL BRACKET SUB-ASSEMBLY (for TMMC Made)

HINT:

Use the same procedure described as for the No. 3 instrument panel to cowl brace sub-assembly (for TMC Made).

21. INSTALL NO. 2 HEATER TO REGISTER DUCT SUB-ASSEMBLY

|

(a) Install the No. 2 heater to register duct sub-assembly with the clip. |

|

22. INSTALL NO. 1 CONSOLE BOX DUCT

|

(a) Install the No. 1 console box duct with the clip. |

|

23. INSTALL REAR NO. 3 AIR DUCT (for TMC Made)

|

(a) Attach the claw to install the rear No. 3 air duct. |

|

24. INSTALL REAR NO. 2 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 3 air duct (for TMC Made).

25. INSTALL REAR NO. 4 AIR DUCT (for TMC Made)

|

(a) Attach the claw. |

|

(b) Install the rear No. 4 air duct with the clip.

26. INSTALL REAR NO. 4 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

27. INSTALL REAR NO. 1 AIR DUCT

HINT:

Use the same procedure described as for the rear No. 3 air duct (for TMC Made).

28. INSTALL REAR NO. 2 AIR DUCT (for TMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

29. INSTALL REAR NO. 3 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

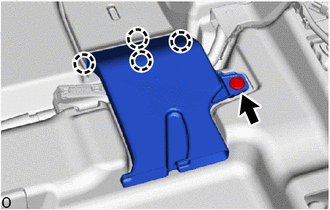

30. INSTALL NO. 3 DASH PANEL INSULATOR PAD

|

(a) Attach the guide to install the No. 3 dash panel insulator pad. |

|

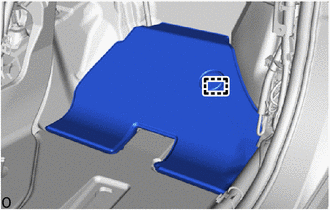

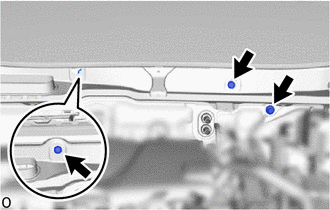

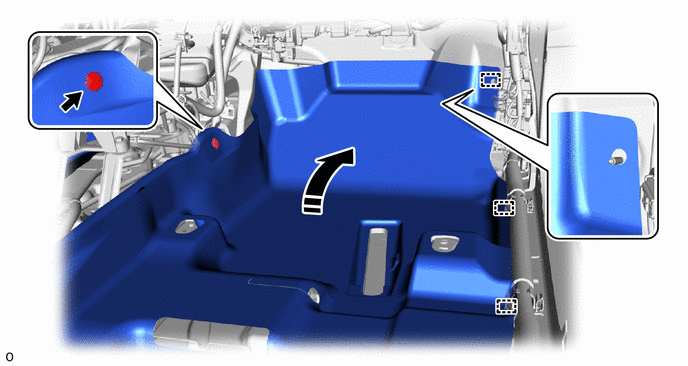

31. INSTALL FRONT FLOOR FRONT CARPET ASSEMBLY

(a) Install the front floor front carpet assembly to its original position as shown in the illustration.

|

Return to Original Position |

- |

- |

(b) Attach the guide.

(c) Install the clip.

(d) Install the front floor front carpet assembly to its original position as shown in the illustration.

|

Return to Original Position |

|

Fastener |

(e) Attach the guide.

(f) Attach each fastener.

(g) Install the clip.

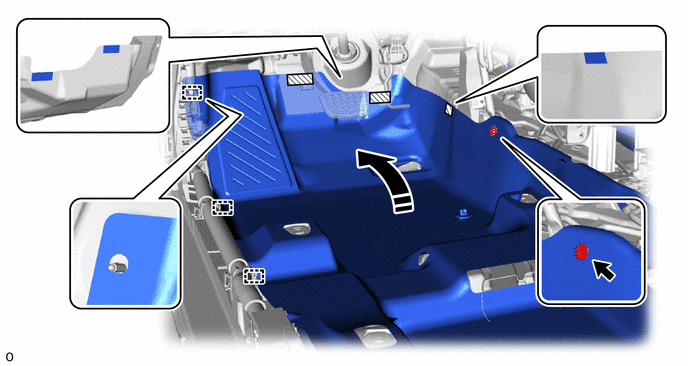

32. INSTALL FRONT FLOOR CAUTION PLATE COVER (w/ Cover)

|

(a) Attach the 2 clips to install the front floor caution plate cover. |

|

(b) While pressing at the positions shown in the illustration, attach the guide and claw.

|

Press Position |

- |

- |

33. INSTALL ACCELERATOR PEDAL ASSEMBLY

34. INSTALL ACCELERATOR PEDAL PAD

35. INSTALL LOWER CENTER PILLAR GARNISH LH

(a) Install the lower center pillar garnish LH.

(b) Return the front door opening trim weatherstrip LH to its original position.

(c) Return the rear door opening trim weatherstrip LH to its original position.

36. INSTALL FRONT SEAT OUTER BELT ASSEMBLY LH

37. INSTALL REAR DOOR SCUFF PLATE LH

38. INSTALL LOWER CENTER PILLAR GARNISH RH

HINT:

Use the same procedure described as for the lower center pillar garnish LH.

39. INSTALL FRONT SEAT OUTER BELT ASSEMBLY RH

HINT:

Use the same procedure described as for the front seat outer belt assembly LH.

40. INSTALL REAR DOOR SCUFF PLATE RH

HINT:

Use the same procedure described as for the rear door scuff plate LH.

41. INSTALL OUTER LAP BELT ANCHOR COVER

42. INSTALL DCM (TELEMATICS TRANSCEIVER) WITH BRACKET (w/ DCM)

43. INSTALL STEERING COLUMN ASSEMBLY

44. INSTALL INSTRUMENT PANEL SAFETY PAD ASSEMBLY

45. INSTALL FRONT SEAT ASSEMBLY LH

(a) for Manual Seat:

(b) for Power Seat:

46. INSTALL FRONT SEAT ASSEMBLY RH

HINT:

Use the same procedure described for the LH side.

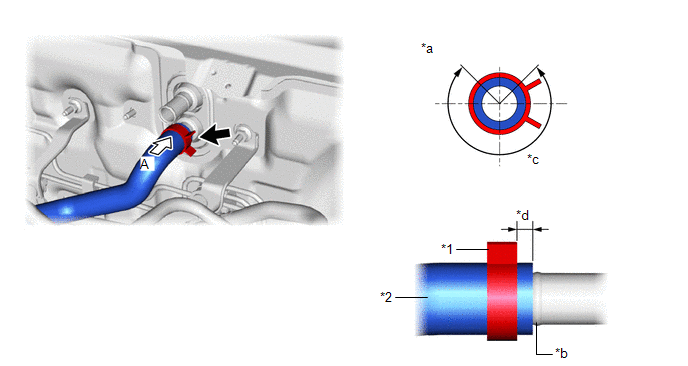

47. CONNECT INLET HEATER WATER HOSE

(a) Connect the inlet heater water hose as shown in the illustration.

NOTICE:

- Do not apply excessive force to the inlet heater water hose.

- Make sure the inlet heater water hose is securely inserted to the stopper. However, If the end of the inlet heater water hose is cut diagonally, it is acceptable for the entire circumference of the tip to not contact the stopper.

- Connect the inlet heater water hose so that its marking faces the top of the vehicle.

|

*1 |

Hose Clip |

*2 |

Inlet Heater Water Hose |

|

*a |

View A |

*b |

Stopper |

|

*c |

Hose Clip Installation Angle (270°) |

*d |

Hose Clip Installation Range (2 to 7 mm (0.0787 to 0.276 in.)) |

(b) Make sure to install the hose clip within the range shown in the illustration.

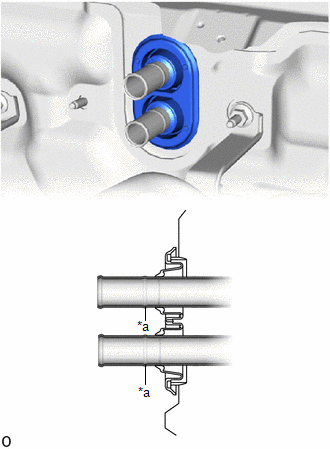

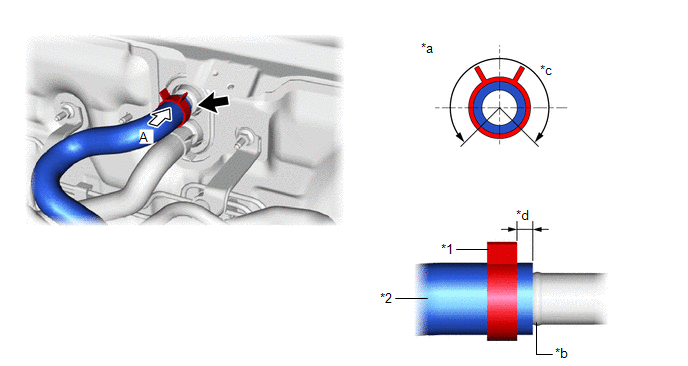

48. CONNECT OUTLET HEATER WATER HOSE

(a) Connect the outlet heater water hose as shown in the illustration.

NOTICE:

- Do not apply excessive force to the outlet heater water hose.

- Make sure the outlet heater water hose is securely inserted to the stopper. However, If the end of the outlet heater water hose is cut diagonally, it is acceptable for the entire circumference of the tip to not contact the stopper.

- Connect the outlet heater water hose so that its marking faces the top of the vehicle.

|

*1 |

Hose Clip |

*2 |

Outlet Heater Water Hose |

|

*a |

View A |

*b |

Stopper |

|

*c |

Hose Clip Installation Angle (270°) |

*d |

Hose Clip Installation Range (2 to 7 mm (0.0787 to 0.276 in.)) |

(b) Make sure to install the hose clip within the range shown in the illustration.

NOTICE:

Make sure that the hose clamps do not contact each other.

49. CONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (w/o Sub-cool Accelerator)

(a) Remove the vinyl tape wrapped around the connection of the air conditioning tube and accessory assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the air conditioning tube and accessory assembly.

Compressor Oil:

ND-OIL 11 or equivalent

NOTICE:

Do not use any compressor oil other than ND-OIL 11 or equivalent. If any compressor oil other than ND-OIL 11 or equivalent is used, compressor motor insulation performance may decrease, resulting in leakage of electric power.

(c) Install the O-ring to the air conditioning tube and accessory assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free from foreign matter.

(d) Connect the air conditioning tube and accessory assembly.

NOTICE:

- Do not apply excessive force to the air conditioning tube and accessory assembly.

- Make sure not to cut the O-ring while installing it. (Cut O-rings cannot be installed)

50. CONNECT SUCTION TUBE SUB-ASSEMBLY B (w/o Sub-cool Accelerator)

(a) Remove the vinyl tape wrapped around the connection of the suction tube sub-assembly B and the suction tube sub-assembly B.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the suction tube sub-assembly B.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the O-ring to the suction tube sub-assembly B.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the suction tube sub-assembly B.

NOTICE:

- Do not apply excessive force to the suction tube sub-assembly B.

- Make sure not to cut the O-ring while installing it. (Cut O-rings cannot be installed)

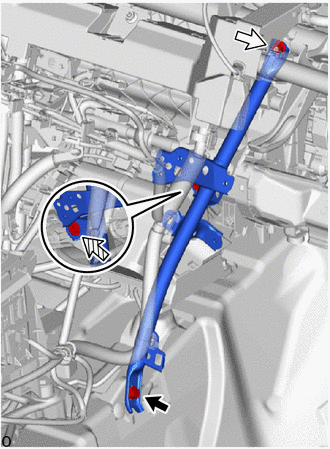

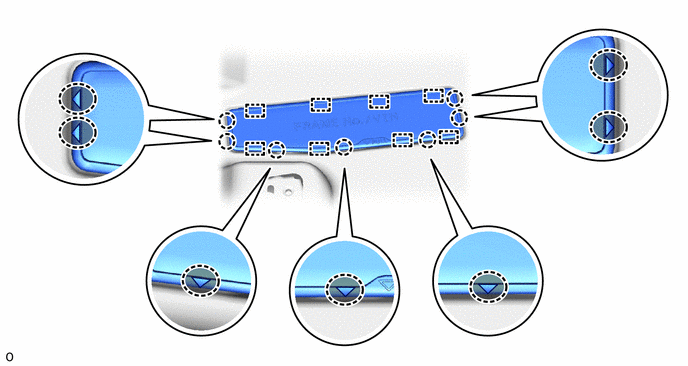

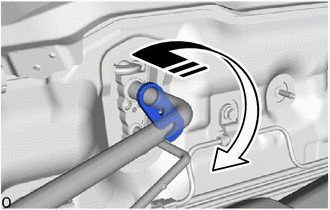

(e) Rotate the 1-point tightening plate as shown in the illustration.

|

Rotate in this Direction |

|

(f) Insert the tube joint into the fitting hole securely and install the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

51. CONNECT NO. 2 AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (for TMC Made with Sub-cool Accelerator)

(a) Remove the vinyl tape wrapped around the connection of the No. 2 air conditioning tube and accessory assembly and the No. 2 air conditioning tube and accessory assembly.

(b) Sufficiently apply compressor oil to 2 new O-rings and the fitting surfaces of the No. 2 air conditioning tube and accessory assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the 2 O-rings to the No. 2 air conditioning tube and accessory assembly.

NOTICE:

Keep the O-rings and O-ring fitting surfaces free of foreign matter.

(d) Connect the No. 2 air conditioning tube and accessory assembly.

NOTICE:

- Do not apply excessive force to the No. 2 air conditioning tube and accessory assembly.

- Make sure not to cut the O-ring while installing it. (Cut O-rings cannot be installed)

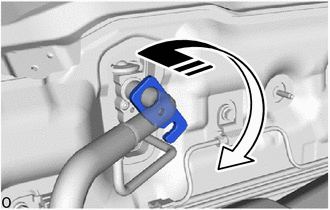

(e) Rotate the 1-point tightening plate as shown in the illustration.

|

Rotate in this Direction |

|

(f) Insert the tube joint into the fitting hole securely and install the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

52. CONNECT SUCTION TUBE SUB-ASSEMBLY B (for TMMC Made with Sub-cool Accelerator)

HINT:

Use the same procedure described as for the No. 2 air conditioning tube and accessory assembly (for TMC Made with Sub-cool Accelerator).

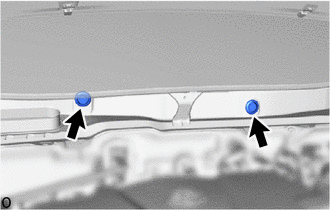

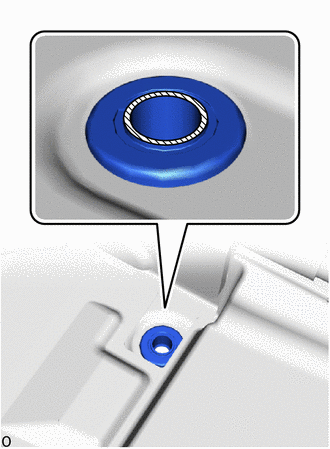

53. INSTALL HOLE PLUG

|

(a) Install the 2 hole plugs. |

|

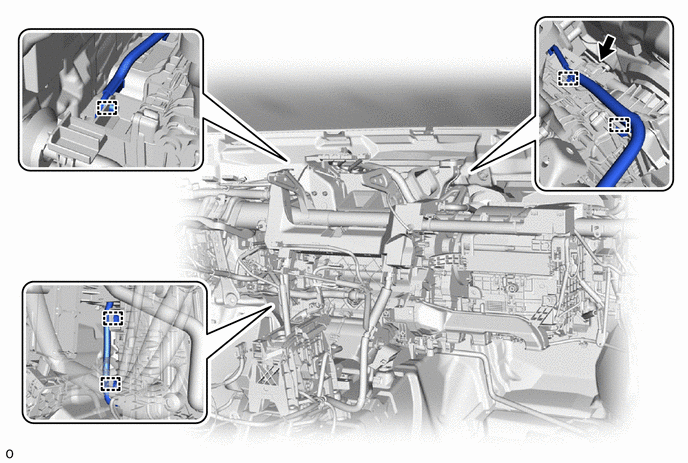

54. INSTALL COWL VENTILATOR PANEL SUB-ASSEMBLY

(a) Install the cowl ventilator panel sub-assembly with the 4 bolts and 4 nuts.

Torque:

Bolt :

5.5 N·m {56 kgf·cm, 49 in·lbf}

Nut :

21 N·m {214 kgf·cm, 15 ft·lbf}

|

Bolt |

|

Nut |

(b) Attach the clamp.

(c) w/ Windshield Deicer System:

|

(1) Attach the clamp. |

|

55. INSTALL COWL VENTILATOR SPLASH SHIELD (for TMC Made)

56. INSTALL COWL VENTILATOR SPLASH SHIELD (for TMMC Made)

HINT:

Use the same procedure described as for the cowl ventilator splash shield (for TMC Made).

57. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

58. ADD ENGINE COOLANT (for Engine)

59. INSPECT FOR COOLANT LEAK (for Engine)

60. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

61. WARM UP COMPRESSOR

62. INSPECT FOR REFRIGERANT LEAK

63. CONNECT SUCTION TUBE SUB-ASSEMBLY B (for TMMC Made with Sub-cool Accelerator)

HINT:

Use the same procedure described as for the No. 2 air conditioning tube and accessory assembly (for TMC Made with Sub-cool Accelerator).

|

|

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; SPECIFICATIONS: STANDARD BOLT: SPECIFIED TORQUE FOR STANDARD BOLTS](/t3Portal/stylegraphics/info.gif)