| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM10000000258BZ |

| Model Year Start: 2023 | Model: RAV4 HV | Prod Date Range: [10/2022 - 10/2023] |

| Title: HEATING / AIR CONDITIONING: COMPRESSOR (for A25A-FXS): REMOVAL; 2023 MY RAV4 HV [10/2022 - 10/2023] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the compressor with motor assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedures |

Effect/Inoperative Function when Necessary Procedures are not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Disconnect cable from negative (-) auxiliary battery terminal |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Parking support brake system (for HV model)* |

|||

|

Pre-collision system |

|||

|

Reset back door close position |

Power back door system (for HV model) |

||

|

Back door lock initialization |

Power door lock control system |

||

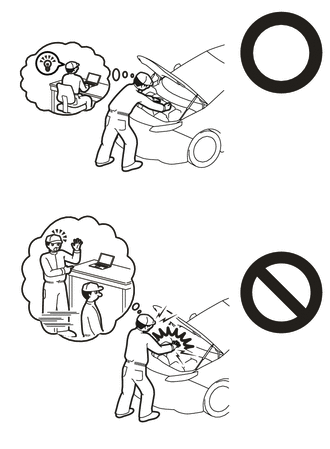

CAUTION:

NOTICE:

- After the ignition switch is turned off, the audio and visual system records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 2 minutes before disconnecting the cable from the negative (-) auxiliary battery terminal.

- When the cable is disconnected from the negative (-) auxiliary battery terminal and the security lock setting has been enabled, multi-display operations will be disabled upon next startup unless the password is entered. Be sure to check the security lock setting before disconnecting the cable from the negative (-) auxiliary battery terminal.

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

2. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

3. REMOVE SERVICE PLUG GRIP

4. CHECK TERMINAL VOLTAGE

(a) Disconnect the engine room main wire.

(b) Remove the connector cover assembly.

(c) Check the terminal voltage.

(d) Install the connector cover assembly.

(e) Connect the engine room main wire.

5. REMOVE FRONT WHEEL RH

6. REMOVE FRONT FENDER MOULDING SUB-ASSEMBLY RH (for TMC Made)

HINT:

Use the same procedure described as for the LH side.

7. REMOVE FRONT FENDER FRONT OUTSIDE MOULDING RH (for TMMC Made)

HINT:

Use the same procedure described as for the front fender moulding sub-assembly RH (for TMC Made).

8. REMOVE FRONT FENDER FRONT SPLASH SHIELD LH

9. REMOVE FRONT FENDER FRONT SPLASH SHIELD RH

10. REMOVE NO. 1 ENGINE UNDER COVER

11. REMOVE FRONT FENDER MUDGUARD RH (w/ Mudguard)

(a) for Short Type:

HINT:

Use the same procedure described as for the LH side.

(b) for Long Type:

HINT:

Use the same procedure described as for the LH side.

12. REMOVE FRONT FENDER APRON SEAL RH (for TMC Made)

13. REMOVE FRONT FENDER APRON SEAL RH (for TMMC Made)

HINT:

Use the same procedure described as for the front fender apron seal RH (for TMC Made).

14. REMOVE FRONT FENDER LINER RH

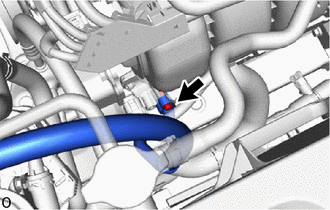

15. DISCONNECT SUCTION HOSE SUB-ASSEMBLY

|

(a) Remove the bolt and disconnect the suction hose sub-assembly. NOTICE: Do not apply excessive force to the suction hose sub-assembly. |

|

(b) Remove the O-ring from the suction hose sub-assembly.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering them.

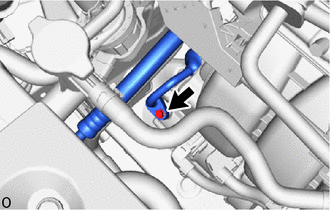

16. DISCONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE

|

(a) Remove the bolt and disconnect the No. 1 cooler refrigerant discharge hose. NOTICE: Do not apply excessive force to the No. 1 cooler refrigerant discharge hose. |

|

(b) Remove the O-ring from the No. 1 cooler refrigerant discharge hose.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent moisture and foreign matter from entering them.

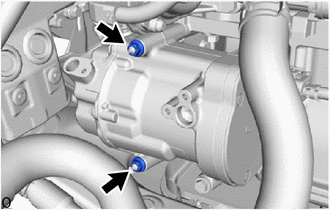

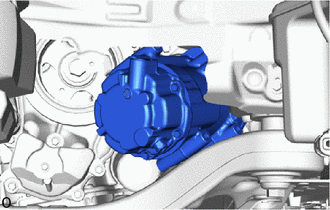

17. REMOVE COMPRESSOR WITH MOTOR ASSEMBLY

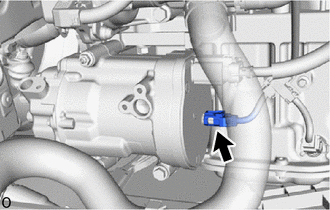

(a) Disconnect the connector (A).

|

Connector (A) |

|

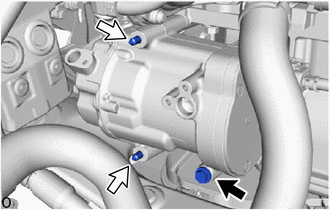

(b) Remove the 2 nuts. |

|

(c) Using an E8 "TORX" socket wrench, remove the 2 stud bolts and bolt.

NOTICE:

Do not drop or subject the parts to any impact.

|

Bolt |

|

Stud Bolt |

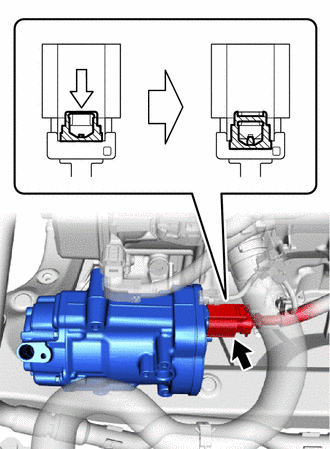

(d) Slide the green-colored lock of the connector (B) as shown in the illustration to release it and disconnect the connector.

|

Connector (B) |

|

Slide |

|

Green-colored Lock |

CAUTION:

Make sure to wear insulated gloves.

NOTICE:

Insulate the disconnected terminals and connector with insulating tape.

|

(e) Remove the compressor with motor assembly from the location shown in the illustration. NOTICE: Do not damage surrounding parts. |

|

|

|

|

![2023 MY RAV4 HV [10/2022 - 10/2023]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for HV Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)