-

If transaxle compensation code read from ECM

- Perform reset memory

- Transfer transaxle compensation code

- Perform road test to allow ECM to learn

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM1000000025RBB |

| Model Year Start: 2023 | Model: RAV4 | Prod Date Range: [10/2022 - 10/2023] |

| Title: UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE ASSEMBLY: REMOVAL; 2023 MY RAV4 [10/2022 - 10/2023] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during automatic transaxle assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Battery terminal is disconnected/reconnected |

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes) |

Stop and start system |

|

|

Perform steering sensor zero point calibration |

Lane control system |

||

|

Parking support brake system (for Gasoline model)* |

|||

|

Pre-collision system |

|||

|

Reset back door close position |

Power back door system (for Gasoline model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

ECM |

Perform Vehicle Identification Number (VIN) or frame number registration |

DTC P063051 is output |

|

|

Code registration |

Engine start function |

||

|

|

|

||

|

|||

|

Exhaust system parts |

Inspection after repair |

|

|

|

Engine assembly |

Inspection after repair |

||

|

Perform road test to allow ECM to learn |

|

||

|

Starter assembly NOTICE: When the starter assembly is replaced, "ST NO. 1 relay" and "ST NO. 2 relay" must be also replaced. |

Clear the number of starter operations |

Stop and start system |

|

|

Automatic transaxle assembly |

|

|

|

|

Automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

for GF2A:

|

Disconnect system function check |

Dynamic torque vectoring AWD system |

|

|

Front bumper assembly (Including removal and installation) |

Front television camera view adjustment |

Panoramic view monitor system (for Gasoline model) |

|

|

Suspension, tires, etc. |

Television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Panoramic view monitor system (for Gasoline model) |

||

|

Front wheel alignment adjustment |

|

VSC malfunction |

|

NOTICE:

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Battery Terminal

|

System Name |

See Procedure |

|---|---|

|

Vehicle enrolled in Toyota Audio Multimedia system or safety connect system |

6 minutes |

|

Vehicle not enrolled in Toyota Audio Multimedia system and safety connect system |

1 minute |

CAUTION:

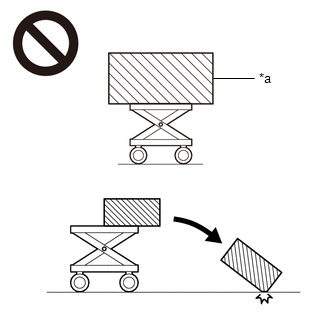

-

The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop or the engine assembly with transaxle may fall off the engine lifter.

*a

An Object Exceeding Weight Limit of Engine Lifter

-

To prevent burns, do not touch the engine, exhaust manifold or other high temperature components while the engine is hot.

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

2. REMOVE FLYWHEEL HOUSING UNDER COVER

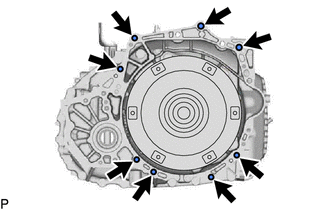

3. REMOVE DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

|

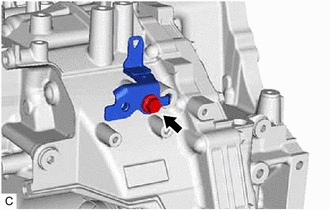

(a) Turn the crankshaft to gain access to the 6 drive plate and torque converter assembly setting bolts and remove each drive plate and torque converter assembly setting bolt while holding the crankshaft pulley bolt with a wrench. HINT: There will be one black-colored drive plate and torque converter assembly setting bolt. |

|

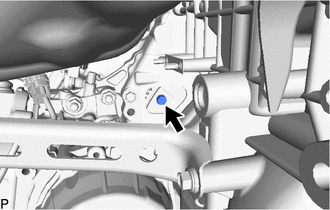

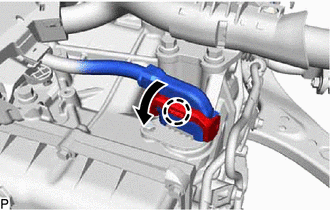

4. DISCONNECT VACUUM HOSE

|

(a) Disconnect the vacuum hose from the vacuum hose connector. |

|

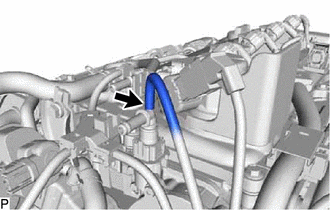

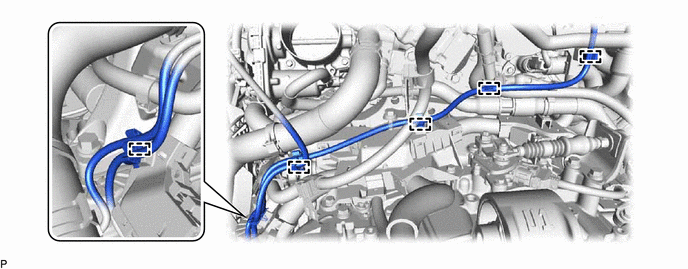

(b) Disengage the 5 clamps to disconnect the vacuum hose from the automatic transaxle assembly.

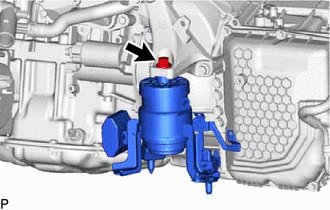

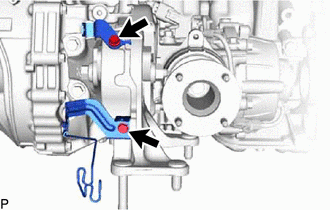

5. REMOVE FLOW SHUTTING VALVE (NO. 1 WATER BY-PASS HOSE)

6. DISCONNECT WATER BY-PASS HOSE ASSEMBLY

7. REMOVE BREATHER PLUG HOSE

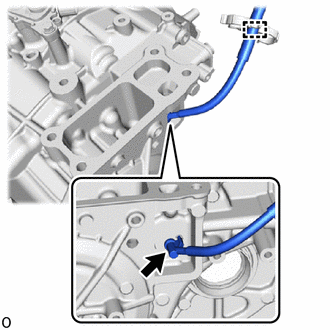

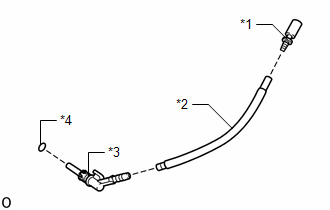

|

(a) Disengage the hose clamp to disconnect the breather plug hose. |

|

(b) Remove the breather plug hose from the automatic transmission case sub-assembly.

|

(c) Remove the O-ring from the breather plug. |

|

(d) Remove the breather plug sub-assembly and breather plug from the breather plug hose.

8. REMOVE STEERING GEAR HEAT INSULATOR

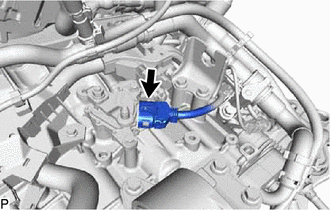

9. DISCONNECT WIRE HARNESS

|

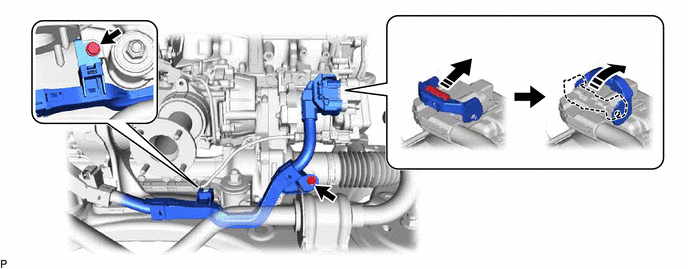

(a) Disengage the claw, rotate the lever and disconnect the transmission wire connector. |

|

|

(b) Disconnect the park/neutral position switch assembly connector. |

|

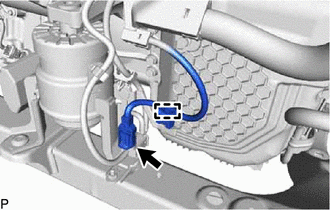

|

(c) Disengage the wire harness clamp and disconnect the vacuum switching valve (for active control engine mount system) connector. |

|

(d) Disconnect the rack and pinion power steering gear assembly connector.

HINT:

Release the lock before rotating the lock lever.

(e) Remove the 2 bolts to disconnect the wire harness from the rack and pinion power steering gear assembly.

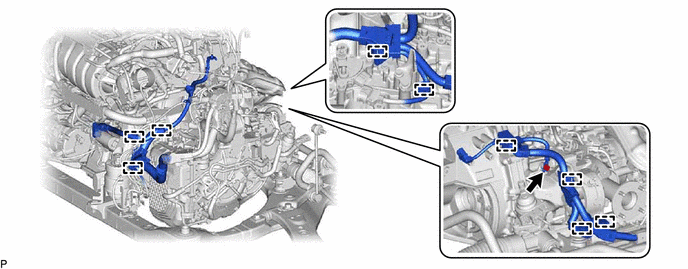

(f) for Transfer (GF1A):

(1) Remove the bolt.

(2) Disengage the 9 wire harness clamps to disconnect the wire harness.

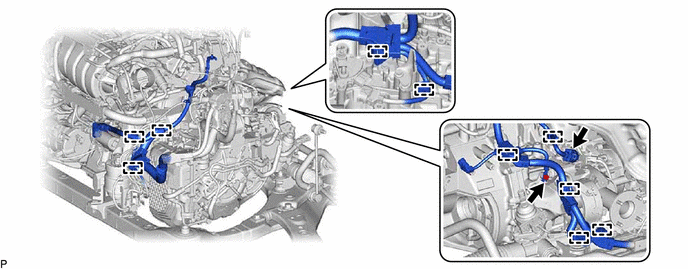

(g) for Transfer (GF2A):

(1) Remove the bolt.

(2) Disengage the 10 wire harness clamps and transfer wire harness connector to disconnect the wire harness.

|

(h) Remove the 2 bolts. |

|

(i) Disengage the wire harness clamp to disconnect the wire harness from the automatic transaxle assembly.

10. REMOVE FLYWHEEL HOUSING SIDE COVER

11. REMOVE STARTER ASSEMBLY

12. REMOVE FUEL DELIVERY GUARD

13. INSTALL ENGINE HANGERS

14. REMOVE FRONT FRAME ASSEMBLY

15. REMOVE FRONT ENGINE MOUNTING INSULATOR

|

(a) Remove the bolt and front engine mounting insulator from the transverse engine engine mounting bracket. |

|

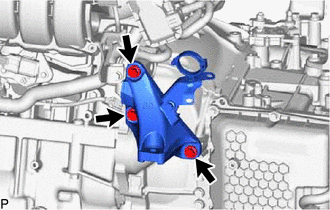

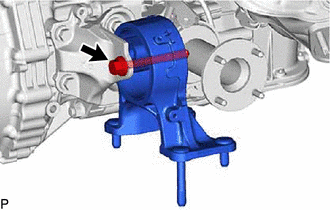

16. REMOVE TRANSVERSE ENGINE ENGINE MOUNTING BRACKET

|

(a) Remove the 3 bolts and transverse engine engine mounting bracket from the transaxle housing. |

|

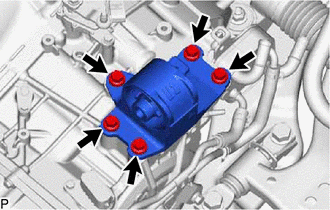

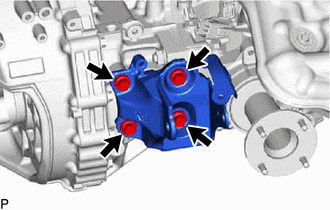

17. REMOVE ENGINE MOUNTING INSULATOR LH

|

(a) Remove the 5 bolts and engine mounting insulator LH from the automatic transaxle case sub-assembly. |

|

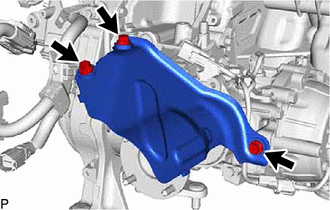

18. REMOVE PROPELLER SHAFT HEAT INSULATOR

|

(a) Remove the 3 bolts and propeller shaft heat insulator from the automatic transaxle assembly. |

|

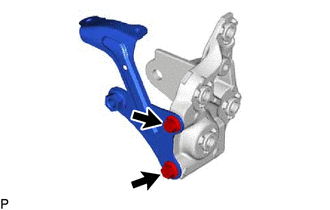

19. REMOVE REAR ENGINE MOUNTING INSULATOR

|

(a) Remove the 2 bolts and 2 wire harness clamp brackets from the rear engine mounting insulator. |

|

|

(b) Remove the bolt, nut and rear engine mounting insulator from the rear engine mounting bracket sub-assembly. |

|

20. REMOVE REAR ENGINE MOUNTING BRACKET SUB-ASSEMBLY

|

(a) Remove the 4 bolts and rear engine mounting bracket sub-assembly from the transaxle housing. |

|

|

(b) Remove the 2 bolts and No. 2 rear engine mounting bracket from the rear engine mounting bracket. |

|

21. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

|

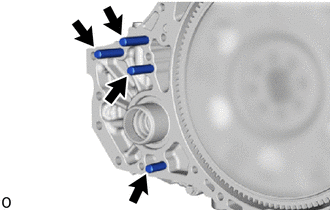

(a) Remove the 8 bolts and automatic transaxle assembly. NOTICE: To prevent damage to the 2 knock pins, do not pry between the automatic transaxle assembly and engine assembly. |

|

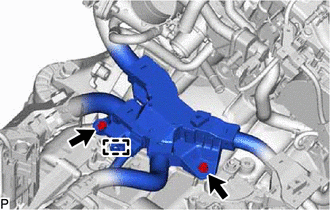

22. DISCONNECT OUTLET NO. 1 OIL COOLER HOSE

23. DISCONNECT INLET NO. 1 OIL COOLER HOSE

24. REMOVE NO. 1 OIL COOLER TUBE SUB-ASSEMBLY WITHOUT HOSE

25. REMOVE TRANSMISSION OIL COOLER

26. REMOVE NO. 1 TRANSMISSION CONTROL CABLE BRACKET

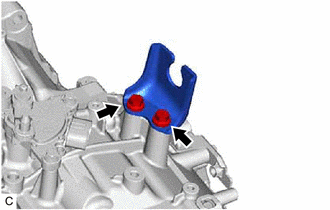

|

(a) Remove the 2 bolts and No. 1 transmission control cable bracket from the automatic transaxle case sub-assembly. |

|

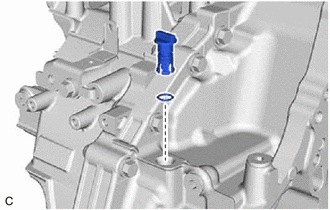

27. REMOVE TRANSMISSION CASE PLUG ASSEMBLY

|

(a) Remove the transmission case plug assembly from the transaxle housing. |

|

(b) Remove the O-ring from the transmission case plug assembly.

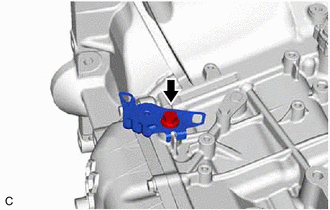

28. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Remove the bolt and wire harness clamp bracket from the automatic transaxle case sub-assembly. |

|

|

(b) Remove the bolt and wire harness clamp bracket from the automatic transaxle case sub-assembly. |

|

|

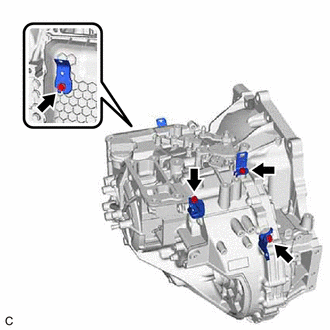

(c) Remove the 4 bolts and 4 wire harness clamp brackets from the automatic transaxle case sub-assembly and transmission case side cover. |

|

29. REMOVE TRANSFER ASSEMBLY

30. REMOVE TRANSFER AND TRANSAXLE SETTING STUD BOLT

HINT:

It is not necessary to remove the transfer and transaxle setting stud bolts unless they are being replaced.

|

(a) for Automatic Transaxle Assembly Side: Remove the 4 transfer and transaxle setting stud bolts. NOTICE: There are 2 types of transfer assembly installation conditions, a type using only nuts and a type using nuts and bolts. Removal stud bolts according to the transfer assembly installation condition of the vehicle. |

|

(b) for Transfer Side:

31. REMOVE TORQUE CONVERTER ASSEMBLY

(a) Remove the torque converter assembly from the automatic transaxle assembly.

NOTICE:

Remove the torque converter assembly from the input shaft horizontally.

32. INSPECT TORQUE CONVERTER ASSEMBLY

33. INSPECT DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

|

|

|

![2023 MY RAV4 [10/2022 - 10/2023]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for Gasoline Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)