- Bleed air

- Perform "Reset Memory"

- Perform "Calibration"

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM1000000026Q77 |

| Model Year Start: 2023 | Model: RAV4 | Prod Date Range: [10/2022 - 10/2023] |

| Title: BRAKE SYSTEM (OTHER): BRAKE BOOSTER (w/o Vacuum Brake Booster): REMOVAL; 2023 MY RAV4 RAV4 HV [10/2022 - 10/2023] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during brake booster with master cylinder assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced (for HV Model)

|

Replaced Part or Performed Procedure |

Necessary procedures |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Disconnect cable from negative (-) auxiliary battery terminal |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Parking support brake system (for HV model)* |

|||

|

Pre-collision system |

|||

|

Reset back door close position |

Power back door system (for HV model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

No. 1 Skid control ECU (brake booster with master cylinder assembly) |

|

|

|

NOTICE:

- After the ignition switch is turned off, the audio and visual system records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 2 minutes before disconnecting the cable from the negative (-) auxiliary battery terminal.

- When the cable is disconnected from the negative (-) auxiliary battery terminal and the security lock setting has been enabled, multi-display operations will be disabled upon next startup unless the password is entered. Be sure to check the security lock setting before disconnecting the cable from the negative (-) auxiliary battery terminal.

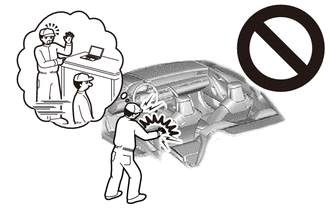

- While the auxiliary battery is connected, even if the power switch is off, the brake control system activates when the brake pedal is depressed or any door courtesy switch turns on. Therefore, when servicing the brake system components, do not operate the brake pedal or open/close the doors while the auxiliary battery is connected. (w/o vacuum brake booster)

-

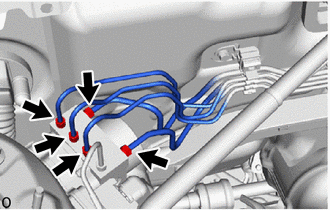

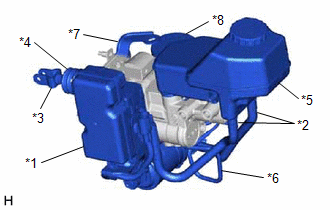

Do not carry the brake booster with master cylinder assembly by the parts shown in the illustration.

*1

No. 1 Skid Control ECU

*2

Reservoir Hose

*3

Master Cylinder Push Rod Clevis

*4

Boot

*5

Reservoir

*6

Brake Actuator Tube

*7

No. 1 Wire Clamp Bracket

*8

Brake Booster with Accumulator Pump Assembly

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read precaution thoroughly before servicing.

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

2. PERFORM ACCUMULATOR PRESSURE ZERO DOWN

(a) Using the GTS, perform the accumulator pressure zero down operation.

(1) Select "Motor Deactivate" on the "ECB Utility" screen.

Chassis > Brake/EPB > Utility

|

Tester Display |

|---|

|

ECB Utility |

(2) Perform "Motor Deactivate" according to the display on the GTS.

(3) Select "ECB Deactivate" on the "ECB Utility" screen.

Chassis > Brake/EPB > Utility

|

Tester Display |

|---|

|

ECB Utility |

(4) Perform "ECB Deactivate" according to the display on the GTS.

(5) Depress the brake pedal 40 times or more to return all the fluid in the accumulator back to the reservoir.

HINT:

A buzzer may sound due to low accumulator pressure. As this is not a malfunction, continue the procedure.

(6) Check that the brake pedal is firm.

NOTICE:

If the brake pedal is not firm or the pump motor continues to operate even after depressing the brake pedal 40 times or more, the accumulator pressure zero down operation is not complete.

(7) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) When the accumulator pressure zero down could not be performed using the GTS.

NOTICE:

If DTCs are output, the accumulator pressure zero down operation may not be complete. In this case, perform the following procedure.

|

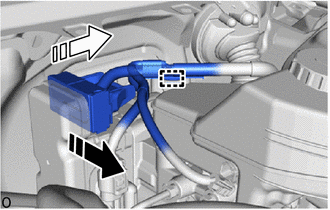

(1) With the ignition switch off, disconnect the brake booster with master cylinder assembly connector. NOTICE: Be careful not to allow any brake fluid to enter the connector. |

|

(2) Depress the brake pedal 40 times or more to return all the fluid in the accumulator back to the reservoir.

(3) Check that the brake pedal is firm.

NOTICE:

If the brake pedal is not firm or the pump motor continues to operate even after depressing the brake pedal 40 times or more, the accumulator pressure zero down operation is not complete.

(4) Disconnect the cable from the negative (-) auxiliary battery terminal.

3. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

4. REMOVE COWL VENTILATOR SPLASH SHIELD

5. REMOVE COWL VENTILATOR PANEL SUB-ASSEMBLY

6. REMOVE ECM

7. DRAIN BRAKE FLUID

NOTICE:

If brake fluid leaks onto any painted surface, immediately wash it off.

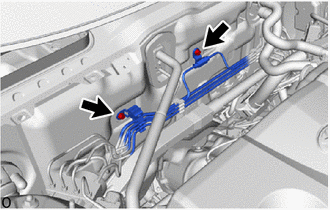

8. DISCONNECT ENGINE ROOM MAIN WIRE

|

(a) Disconnect the connector from the brake booster with master cylinder assembly. |

|

|

(b) Disconnect the brake fluid level warning switch connector. |

|

(c) Release the lock lever and disconnect the connector from the brake booster with master cylinder assembly.

|

Release the lock lever |

|

Disconnect the connector |

NOTICE:

Be careful not to allow any brake fluid to enter the connector.

(d) Disengage the clamp to separate the engine room main wire from the brake booster with master cylinder assembly.

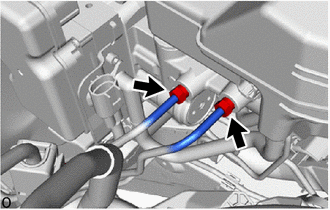

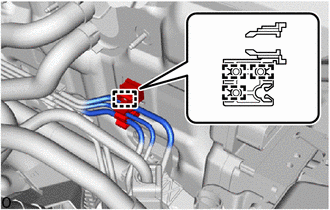

9. DISCONNECT BRAKE LINE

|

(a) Using a union nut wrench, disconnect the 2 brake lines from the brake booster with master cylinder assembly. NOTICE:

|

|

|

(b) Use tags or make a memo to identify the places to reconnect the brake lines. |

|

|

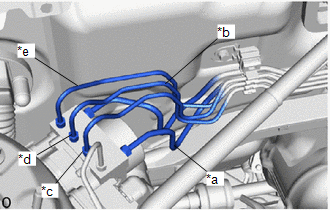

(c) Using a union nut wrench, disconnect the 5 brake lines from the brake actuator assembly. NOTICE:

|

|

|

(d) Remove the 2 bolts to separate the brake lines. |

|

|

(e) Disengage the 4 clamps to remove the No. 2 brake tube clamp from the brake lines. NOTICE: Do not kink or damage the brake lines. |

|

10. REMOVE LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

11. REMOVE NO. 1 AIR DUCT (for TMC Made)

12. REMOVE NO. 2 AIR DUCT SUB-ASSEMBLY (for TMMC Made)

13. REMOVE STOP LIGHT SWITCH ASSEMBLY

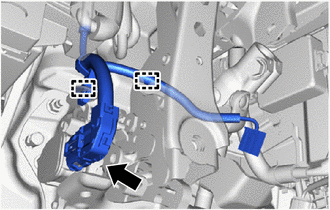

14. DISCONNECT ENGINE ROOM MAIN WIRE

|

(a) Disconnect the connector from the brake pedal stroke sensor assembly. |

|

(b) Disengage the 2 clamps to separate the engine room main wire from the brake pedal support assembly.

15. REMOVE BRAKE PEDAL RETURN SPRING

16. REMOVE PUSH ROD PIN

17. REMOVE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY

|

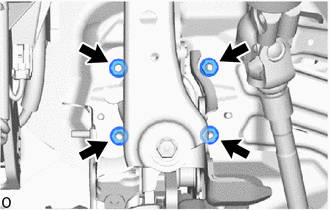

(a) Remove the 4 nuts and brake booster with master cylinder assembly. NOTICE:

|

|

18. REMOVE BRAKE BOOSTER GASKET

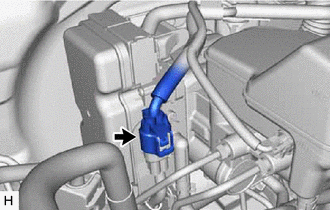

19. REMOVE NO. 2 RESERVOIR HOSE

HINT:

Perform this procedure only when replacement of the No. 2 reservoir hose is necessary.

|

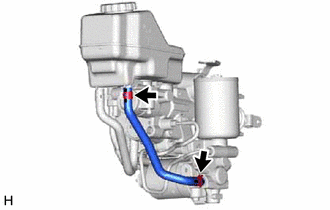

(a) Slide the 2 clips and remove the No. 2 reservoir hose. |

|

(b) Remove the 2 clips from the No. 2 reservoir hose.

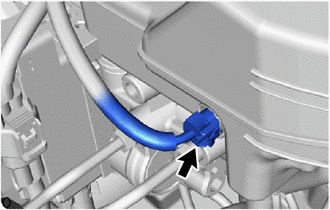

20. REMOVE NO. 1 RESERVOIR HOSE

HINT:

Perform this procedure only when replacement of the No. 1 reservoir hose is necessary.

|

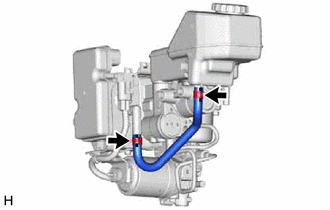

(a) Slide the 2 clips and remove the No. 1 reservoir hose. |

|

(b) Remove the 2 clips from the No. 1 reservoir hose.

21. REMOVE NO. 1 WIRE CLAMP BRACKET

HINT:

Perform this procedure only when replacement of the No. 1 wire clamp bracket is necessary.

|

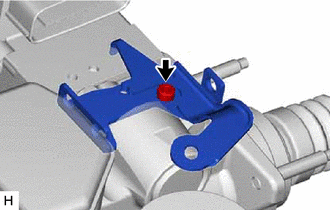

(a) Using a 5 mm long hexagon socket wrench, remove the bolt and No. 1 wire clamp bracket. |

|

|

|

|

![2023 MY RAV4 HV [10/2022 - 10/2023]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for HV Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)