- Perform "Reset Memory"

- Perform "Calibration"

| Last Modified: 09-02-2025 | 6.11:8.1.0 | Doc ID: RM100000002FRDK |

| Model Year Start: 2024 | Model: RAV4 HV | Prod Date Range: [10/2023 - ] |

| Title: REAR SUSPENSION: REAR SUSPENSION MEMBER (for HV Model AWD): REMOVAL; 2024 - 2025 MY RAV4 HV [10/2023 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear suspension member sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Auxiliary battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Parking support brake system (for HV model)* |

|||

|

Pre-collision system |

|||

|

Reset back door close position |

Power back door system |

||

|

Back door lock initialization |

Power door lock control system |

||

|

Rear wheel alignment adjustment |

|

|

|

|

Suspension, tires, etc. |

Television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Parking assist ECU initialization |

Panoramic view monitor system (for HV model) |

||

|

Gas leak from exhaust system is repaired |

Inspection after repair |

|

|

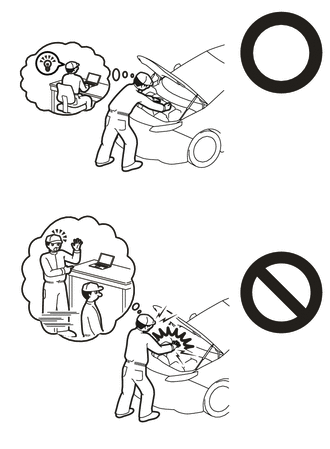

CAUTION:

-

This vehicle has contains high voltage circuits standardized with orange colored wiring and connectors, so follow the instructions in this manual to perform the procedures correctly.

Click here

- If the correct procedures are not followed according to the instructions in this manual, there is a danger of electric shock from the high voltage circuits.

-

Be sure to wear insulating gloves when working on high voltage wiring or components.

- If work is performed without wearing insulating gloves, there is a danger of electric shock.

-

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

NOTICE:

- After the ignition switch is turned off, the audio and visual system records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 2 minutes before disconnecting the cable from the negative (-) auxiliary battery terminal.

- When the cable is disconnected from the negative (-) auxiliary battery terminal and the security lock setting has been enabled, multi-display operations will be disabled upon next startup unless the password is entered. Be sure to check the security lock setting before disconnecting the cable from the negative (-) auxiliary battery terminal.

PROCEDURE

PROCEDURE

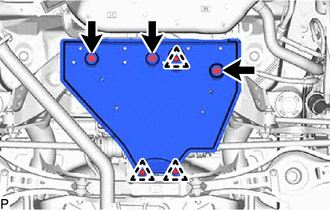

1. REMOVE NO. 1 FLOOR UNDER COVER (w/ NO. 1 FLOOR UNDER COVER)

|

(a) Remove the 3 bolts, 3 clips and No. 1 floor under cover from the rear suspension member sub-assembly. |

|

2. REMOVE REAR STABILIZER BAR

3. REMOVE REAR DRIVE SHAFT ASSEMBLY LH

4. REMOVE REAR DRIVE SHAFT ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

5. REMOVE REAR NO. 2 SUSPENSION ARM ASSEMBLY LH

6. REMOVE REAR NO. 2 SUSPENSION ARM ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

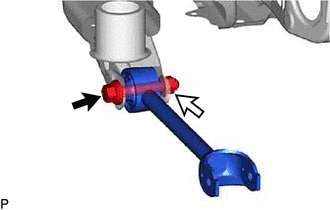

7. REMOVE REAR NO. 1 SUSPENSION ARM ASSEMBLY LH

|

(a) Remove the bolt, nut and rear No. 1 suspension arm assembly from the rear suspension member sub-assembly. NOTICE: Because the nut has its own stopper, do not turn the nut. Loosen the bolt with the nut secured. |

|

8. REMOVE REAR NO. 1 SUSPENSION ARM ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

9. REMOVE SERVICE PLUG GRIP

10. DISCONNECT ENGINE ROOM MAIN WIRE

11. REMOVE CONNECTOR COVER ASSEMBLY

12. CHECK TERMINAL VOLTAGE

13. INSTALL CONNECTOR COVER ASSEMBLY

14. CONNECT ENGINE ROOM MAIN WIRE

15. REMOVE REAR SEAT ASSEMBLY

16. REMOVE CHILD RESTRAINT SEAT ANCHOR BRACKET SUB-ASSEMBLY LH

17. REMOVE TONNEAU COVER ASSEMBLY (w/ Tonneau Cover)

18. REMOVE DECK BOARD ASSEMBLY

19. REMOVE REAR NO. 3 FLOOR BOARD

20. REMOVE REAR DECK FLOOR BOX (w/o Spare Tire)

21. REMOVE REAR FLOOR FINISH PLATE

22. REMOVE REAR NO. 1 FLOOR MAT SUPPORT SIDE PLATE

23. REMOVE REAR DOOR SCUFF PLATE LH

24. REMOVE REAR DOOR OPENING TRIM WEATHERSTRIP LH

25. REMOVE REAR SEAT SIDE GARNISH LH

26. REMOVE TETHER ANCHOR BRACKET SET

27. REMOVE LUGGAGE HOLD BELT STRIKER ASSEMBLY

28. REMOVE DECK TRIM SIDE PANEL ASSEMBLY LH

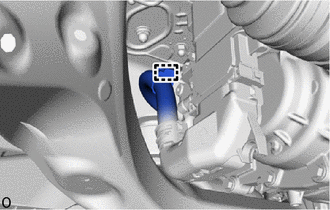

29. DISCONNECT FLOOR UNDER WIRE

CAUTION:

Be sure to wear insulated gloves.

NOTICE:

Insulate the disconnected connectors with insulating tape.

|

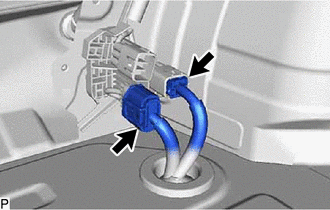

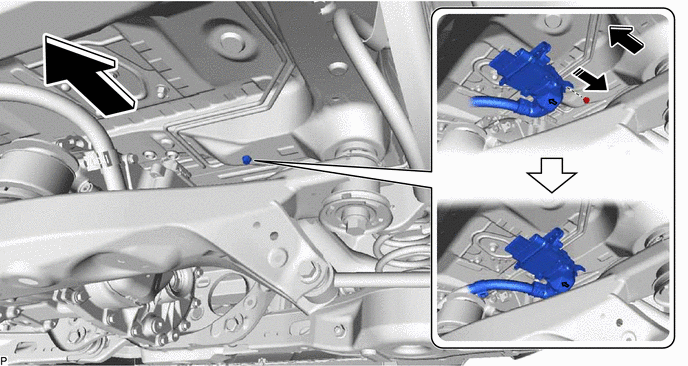

(a) Disengage the clamp. |

|

|

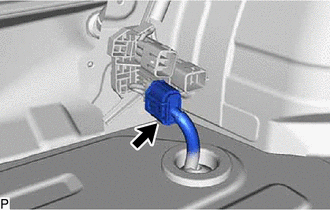

(b) Remove the 2 bolts and HV floor under wire from the rear traction motor with transaxle assembly. NOTICE:

|

|

(c) Temporarily install the HV floor under wire as shown in the illustration.

|

Front of the Vehicle |

- |

- |

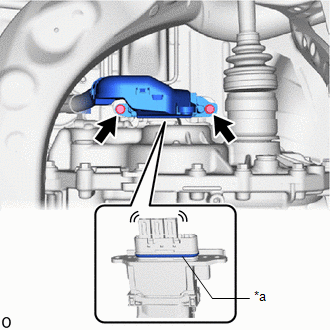

30. REMOVE REAR SUSPENSION MEMBER SUB-ASSEMBLY

|

(a) w/ Height Control Sensor: (1) Disconnect the 2 connectors. |

|

|

(b) w/o Height Control Sensor: (1) Disconnect the connector. |

|

(c) Remove the grommet of the wire harness and pass the connector through the hole to the outside of the vehicle.

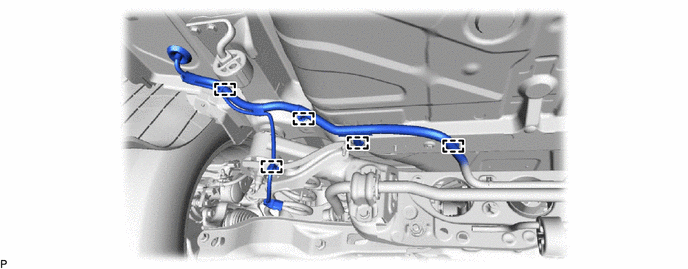

(d) w/ Height Control Sensor:

(1) Disengage the 5 clamps to separate the wire harness.

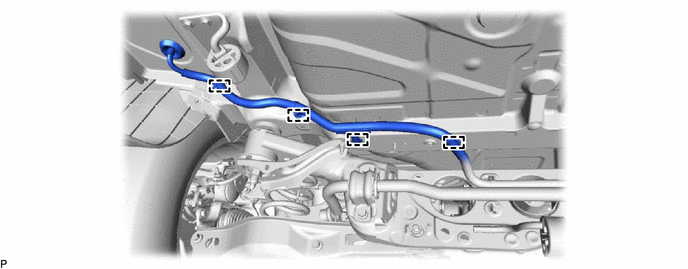

(e) w/o Height Control Sensor:

(1) Disengage the 4 clamps to separate the wire harness.

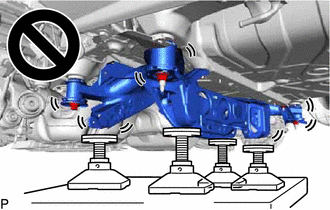

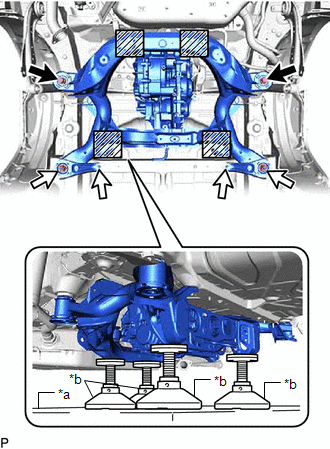

(f) Using an engine lifter and 4 attachments or equivalent tools, support the rear suspension member sub-assembly as shown in the illustration.

CAUTION:

- The rear suspension member sub-assembly is a very heavy component. Make sure that it is supported securely.

- If the rear suspension member sub-assembly is not securely supported, it may drop, resulting in serious injury.

NOTICE:

Use attachments or equivalent tools to keep the rear suspension member sub-assembly level.

|

*a |

Engine Lifter |

|

*b |

Attachment |

|

Attachment and Wooden Block Placement Location |

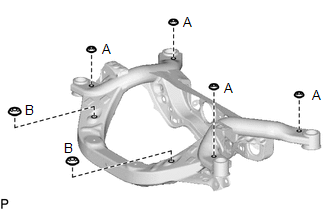

(g) Remove the 2 bolts, 4 nuts, 2 rear suspension member lower stoppers, rear suspension member lower brace LH and rear suspension member lower brace RH.

(h) Slowly lower the rear suspension member sub-assembly.

NOTICE:

When lowering the rear suspension member sub-assembly, be careful not to damage the vehicle body or other components installed to the vehicle.

(i) for TMC Made:

(1) Remove the 4 rear suspension member cushions from the rear suspension member sub-assembly.

HINT:

Make sure to place an identification mark on the rear suspension member cushion so that they can be reinstalled to their original positions.

(j) for TMMC Made:

(1) Remove the 2 rear suspension member cushions and 2 upper differential support member stoppers from the rear suspension member sub-assembly.

HINT:

Make sure to place an identification mark on the rear suspension member cushion and upper differential support member stopper so that they can be reinstalled to their original positions.

31. DISCONNECT WIRE HARNESS

32. REMOVE REAR TRACTION MOTOR WITH TRANSAXLE ASSEMBLY

33. REMOVE REAR UPPER CONTROL ARM ASSEMBLY LH

34. REMOVE REAR UPPER CONTROL ARM ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

35. REMOVE REAR SUSPENSION MEMBER FRONT BODY MOUNTING CUSHION (for LH Side)

36. REMOVE REAR SUSPENSION MEMBER FRONT BODY MOUNTING CUSHION (for RH Side)

HINT:

Perform the same procedure as for the LH side.

37. REMOVE REAR SUSPENSION MEMBER REAR BODY MOUNT CUSHION LH

38. REMOVE REAR SUSPENSION MEMBER REAR BODY MOUNT CUSHION RH

HINT:

Perform the same procedure as for the LH side.

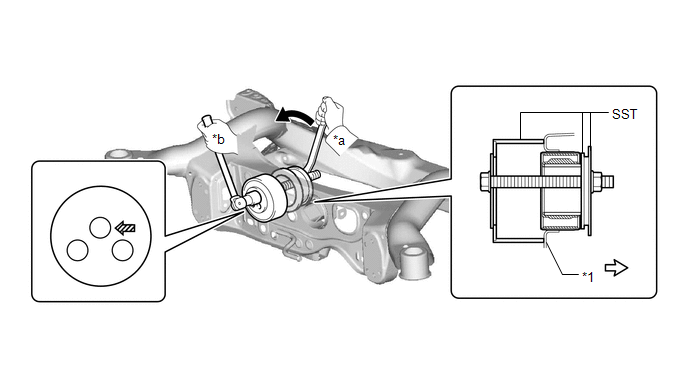

39. REMOVE DIFFERENTIAL MOUNT CUSHION

(a) Using SST, remove the differential mount cushion.

09316-12010 09570-24011

|

*1 |

Rear Suspension Member Sub-assembly |

- |

- |

|

*a |

Turn |

*b |

Hold |

|

Turning Direction |

|

Front of Vehicle |

|

SST Bolt Position |

- |

- |

NOTICE:

- Do not bring SST into contact with the rear suspension member sub-assembly.

- Before using SST, apply grease to SST bolt.

- Set SST in the correct direction.

- Do not tilt the bolt of SST.

- Do not reuse the differential mount cushion.

40. REMOVE HOLE PLUG

|

(a) Remove the 6 hole plugs from the rear suspension member sub-assembly. HINT: There are 2 different shapes of hole plug. |

|

|

|

|

![2024 - 2025 MY RAV4 HV [10/2023 - ]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for HV Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)